Selecting the wrong sex toys supplier can devastate your distribution business. Poor quality products lead to returns, safety complaints, and damaged retail relationships that destroy profitability and market position.

The most successful sex toys distributors partner with established manufacturers like VF Pleasure that offer comprehensive services including custom design, high-quality silicone production, rigorous safety testing, reliable logistics, and ongoing product development to ensure distributors maintain competitive market positions.

I've spent 15 years manufacturing adult products in China, watching distributors struggle with unreliable partners. The right manufacturer makes all the difference between thriving and barely surviving in this competitive market. Let me share insights from working with hundreds of distributors about what truly matters when selecting a manufacturing partner for your adult product business.

What Should Sex Toys Distributors Look for in a Manufacturing Partner?

Many distributors face a painful reality after placing orders - discovering their manufacturer lacks essential capabilities. They end up with inconsistent quality, missed deadlines, and products that don't meet market expectations.

Successful sex toys distributors prioritize manufacturers with at least 10 years of industry experience, in-house R&D capabilities, ISO-certified production facilities, comprehensive material testing, and proven ability to adapt to evolving market trends and regulatory requirements.

Diving Deeper Into Manufacturing Partner Selection

I remember meeting a European distributor at an industry trade show who had just wasted six months and over $50,000 on a failed product launch. Their chosen manufacturer had promised everything but delivered products with safety issues, inconsistent performance, and packaging that didn't meet EU regulations. This painful experience highlights why manufacturing partner selection deserves careful consideration.

Manufacturing capability assessment starts with production facilities. At VF Pleasure, our Guangdong Dongguan factory houses five specialized production lines dedicated to different product categories. This specialization matters because producing quality vibrators requires different expertise than creating male adult toys or thrusting sex toys. Distributors should verify that potential partners have dedicated production environments for their specific product categories.

Material expertise represents another critical factor. The adult product industry has evolved significantly regarding material safety. Our silicone formulations undergo rigorous testing to ensure they meet FDA and EU safety standards. When evaluating manufacturers, ask about their material suppliers, testing protocols, and certification documentation. Reputable manufacturers maintain transparent supply chains and readily provide material safety data sheets.

Quality control systems differentiate professional manufacturers from problematic partners. Our multi-stage QC process includes raw material inspection, in-process checks, finished product testing, and shipment verification. During factory visits, pay attention to how potential partners handle quality issues – are they transparent about challenges and systematic in their approach to improvements? The presence of documented quality procedures and trained QC staff indicates a manufacturer serious about consistency.

Production capacity flexibility also deserves consideration. Market demand fluctuates, requiring manufacturers who can scale production up or down accordingly. Our facility manages orders ranging from 500 to 50,000 units, accommodating both new distributors and established brands. Discuss minimum order quantities and lead time adjustments for different order sizes to ensure alignment with your business model.

Research and development capabilities increasingly separate market leaders from followers. Our R&D center in Shenzhen employs designers and engineers dedicated to creating innovative products and improving existing designs. When evaluating potential partners, inquire about their product development process, typical development timelines, and examples of innovations they've brought to market. Manufacturers investing in R&D will help keep your product line competitive.

| Manufacturing Partner Criteria | Questions to Ask | Red Flags |

|---|---|---|

| Production Experience | Years manufacturing adult products, major clients | General manufacturing without adult product focus |

| Quality Systems | Quality certification, testing procedures | Informal or undocumented quality processes |

| Material Safety | Material certifications, testing frequency | Inability to provide documentation |

| R&D Capabilities | Design team size, innovation examples | Reliance solely on client designs |

| Production Flexibility | MOQ options, capacity scaling | Rigid production requirements |

How Can Custom Manufacturing Elevate Your Distribution Business?

Many distributors struggle with market differentiation when selling the same products as their competitors. This commodity approach leads to price wars, shrinking margins, and vulnerability to market disruptions.

Working with a full-service manufacturer like VF Pleasure enables distributors to develop exclusive product lines with customized features, unique branding, personalized packaging, and tailored marketing support that creates sustainable competitive advantages and stronger retailer relationships.

Diving Deeper Into Custom Manufacturing Benefits

The adult product market has matured significantly, making differentiation increasingly critical for distribution success. Our custom manufacturing services have helped distributors transform from commodity sellers to brand owners with distinctive market positions.

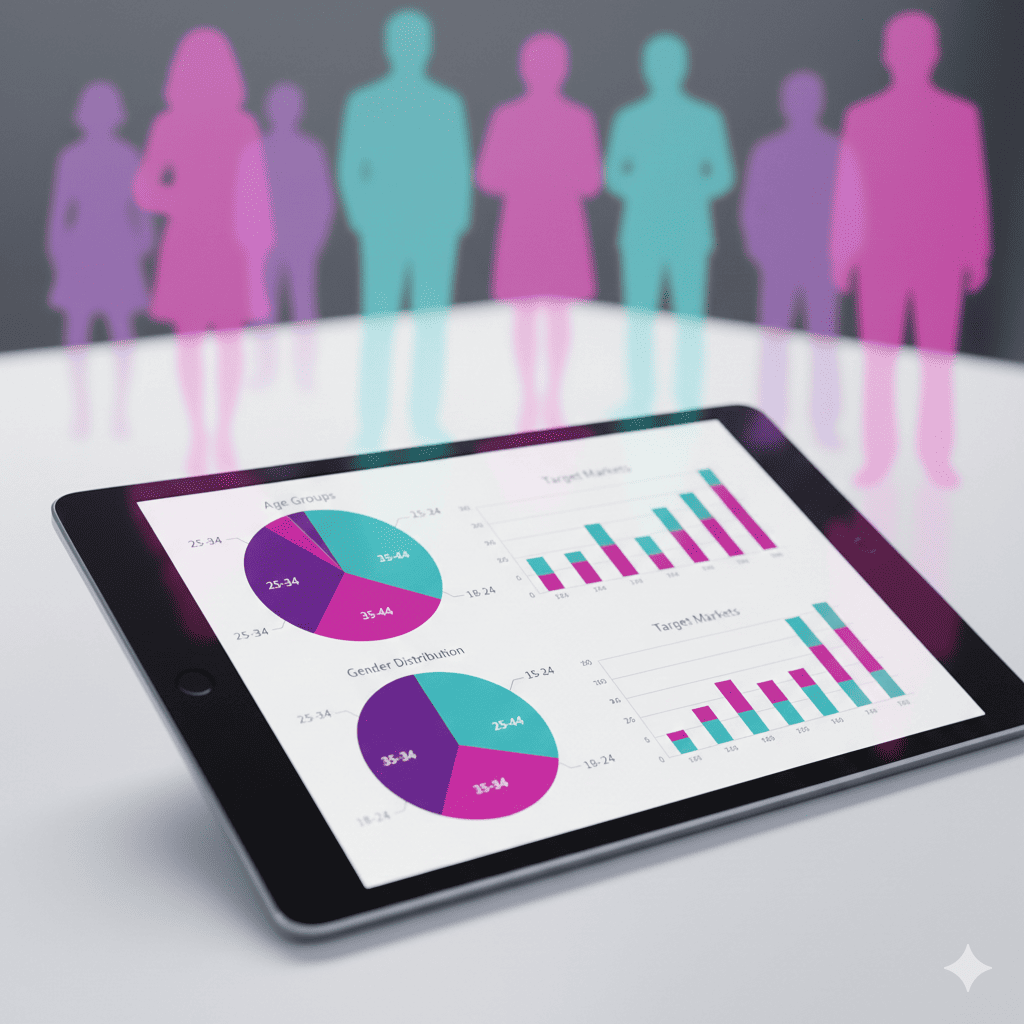

Custom development begins with market analysis. One North American distributor I worked with was struggling with slim margins in the vibrator category. By analyzing their market, we identified an underserved niche for travel-friendly, discreet products with premium performance. We developed a custom line of compact female sex toys that could be marketed at premium price points, doubling their category margins while creating a recognizable product identity.

Product design customization offers multiple approaches based on your business model. Full custom development creates entirely unique products, while semi-custom options modify existing platforms with your specific features. For distributors entering custom manufacturing, we often recommend the semi-custom approach to balance distinctiveness with cost efficiency. This strategy reduced development time by 40% for an Australian distributor while still delivering a product line retailers recognized as unique.

Material and color customization provides another differentiation opportunity. Our silicone formulation capabilities allow for custom textures, colors, and performance characteristics that visually distinguish your products. A European distributor leveraged this capability to create a signature color palette that became instantly recognizable in stores, strengthening their brand identity without requiring completely new product designs.

Packaging customization extends your brand experience beyond the product itself. Our packaging design team works with distributors to create retail-ready presentations that align with specific market positioning, from luxury to lifestyle to value-oriented approaches. Custom packaging has proven particularly valuable for distributors working with major retailers who demand visually distinctive presentations that align with their store environments.

Feature customization tailors product functionality to specific market preferences. Our engineering team can modify vibration patterns, control interfaces, and other functional elements to match regional preferences or distribution channel requirements. This capability helped one Asian distributor create products specifically designed for their market's unique preferences, significantly outperforming imported designs from other regions.

Private labeling represents the most accessible entry point to custom manufacturing. Our private label sex toys program allows distributors to place their branding on established designs, creating market recognition without full custom development costs. This approach has helped numerous distributors transition from anonymous distribution to brand building while minimizing initial investment.

The most successful distributor partnerships involve ongoing development cycles. Rather than one-time projects, we establish product roadmaps that systematically expand and refresh custom product lines. This approach helped one European distributor grow from three initial custom products to a comprehensive 28-item range over three years, securing significant market share against much larger competitors.

What Quality Standards Should Distributors Demand From Manufacturers?

Many distributors discover quality problems only after products reach their warehouses or worse, their customers. These issues damage retailer relationships, trigger costly recalls, and create financial liabilities that can threaten business viability.

Professional sex toys distributors require manufacturing partners with comprehensive quality systems including ISO 9001 certification, material safety testing to FDA and EU standards, electrical safety compliance, performance consistency testing, and documented quality control processes throughout production.

Diving Deeper Into Quality Assurance Requirements

Quality issues represent the most common and costly problems distributors face with adult products. As manufacturing has globalized, the importance of verifiable quality systems has increased dramatically. Having established comprehensive quality protocols at VF Pleasure, I've seen firsthand how proper systems prevent issues that would otherwise devastate distribution businesses.

Material safety certification forms the foundation of product quality. Our silicone formulations undergo testing for biocompatibility, chemical composition, and allergenic compounds before being approved for production. Distributors should request test reports confirming materials meet FDA standards for body-safe applications. These documents provide both regulatory protection and marketing value by verifying product safety claims.

Manufacturing consistency depends on standardized production processes. Our factory utilizes Statistical Process Control (SPC) to monitor critical quality parameters throughout production runs. When evaluating manufacturers, ask about their process control methodologies and how they ensure consistency between production batches. Request documentation of their quality metrics for recent production runs similar to your planned products.

Motor and electronic component reliability directly impacts customer satisfaction and return rates. Our couples toys undergo accelerated life testing simulating years of usage to identify potential failure points before production. When assessing potential manufacturers, inquire about their component selection process, reliability testing protocols, and historical failure rates. Quality manufacturers track this data systematically and use it to continuously improve designs.

Waterproofing integrity testing is particularly critical for adult products. Our testing protocols include both pressure testing and submerged operation testing to verify waterproof claims. Ask potential partners about their waterproofing technologies and validation methods, as this represents a common failure point for less experienced manufacturers.

Product performance validation ensures products deliver the promised user experience. Our testing includes vibration intensity mapping, noise level measurement, and battery life verification across multiple usage scenarios. These objective measurements should align with your market positioning and competitive analysis.

Packaging and shipping durability also require verification. Products must arrive at retail locations in perfect condition despite the rigors of global shipping. Our packaging undergoes drop testing, compression testing, and environmental simulation to ensure it protects products throughout the distribution chain. Review potential partners' packaging validation methods, particularly for fragile or premium products.

Perhaps most importantly, quality documentation provides protection against regulatory challenges. Our quality system maintains complete traceability from raw materials through shipping, with documentation available to support distributors facing customs inquiries or regulatory questions. Verify that potential manufacturing partners maintain organized records that can be provided quickly when needed.

| Quality System Element | Verification Method | Importance |

|---|---|---|

| Material Safety Testing | Request test reports and certifications | Prevents health risks and regulatory issues |

| Production Process Control | Review SOP documentation and process metrics | Ensures consistent quality across production runs |

| Performance Testing | Request test protocols and sample reports | Verifies products meet market expectations |

| Packaging Validation | Review packaging test results | Prevents damage during distribution |

| Documentation System | Verify record retention and accessibility | Provides protection against regulatory challenges |

How Do Logistics and Supply Chain Management Impact Distribution Success?

Unreliable shipping, customs delays, and poor inventory planning create costly disruptions for many distributors. These logistics failures result in out-of-stock situations, excess inventory costs, and missed sales opportunities that directly impact profitability.

Effective manufacturing partners provide distribution logistics support including optimized shipping options, customs documentation assistance, inventory management recommendations, and flexible production scheduling that helps distributors balance inventory costs against product availability.

Having shipped adult products to distributors in over 40 countries, I've learned that logistics excellence often determines business success more than product design or pricing. At about-us, you'll see our commitment to logistics as a core service, not an afterthought.

Shipping cost optimization starts with packaging design. Our engineering team analyzes dimensional weight factors when designing both products and packaging, often reducing shipping costs by 15-25% compared to standard approaches. When evaluating manufacturers, request shipping cost estimates based on actual packaged products rather than theoretical calculations, as differences significantly impact landed costs.

Customs documentation accuracy prevents costly border delays. Our export team specializes in adult product classification, providing proper documentation that minimizes customs scrutiny while maintaining regulatory compliance. Ask potential manufacturing partners about their experience shipping to your specific markets and their procedures for handling customs documentation challenges when they arise.

Inventory level optimization requires collaborative planning. We work with distributors to develop production schedules aligned with their sales cycles, reducing both excess inventory costs and stockout risks. This approach helped one U.S. distributor reduce inventory carrying costs by 22% while improving product availability during peak seasons. Discuss inventory planning capabilities with potential partners, particularly their flexibility in adjusting production schedules as market conditions change.

Order fulfillment options provide strategic advantages for different business models. In addition to traditional bulk shipping to distributor warehouses, we offer drop-shipping services for e-commerce-focused distributors and retail-ready packaging for those supplying major chains. These capabilities have allowed several partners to expand into new channels without significant infrastructure investments.

Lead time management requires transparency and contingency planning. We provide distributors with real-time production status updates and early notification of potential delays, allowing for proactive communication with retail customers. When evaluating manufacturers, inquire about their communication systems for production updates and their track record for on-time delivery during industry peak seasons.

Shipping method diversification has become increasingly important given global logistics disruptions. We maintain relationships with multiple freight forwarders and shipping services, allowing us to pivot quickly when challenges arise in specific shipping lanes. This capability proved invaluable during recent supply chain disruptions when we successfully maintained 94% on-time delivery by utilizing alternative shipping routes for urgent orders.

Return and warranty handling processes deserve particular attention. Our quality systems minimize returns, but we also maintain efficient procedures for addressing the issues that inevitably arise. One European distributor particularly valued our ability to provide technical analysis of returned products, helping identify whether issues stemmed from manufacturing, distribution handling, or customer misuse.

How Can Manufacturers Support Your Market Growth Strategy?

Many distributors find their growth limited by manufacturers focused solely on production rather than business success. This transactional approach prevents distributors from accessing valuable expertise that could accelerate market expansion.

Strategic manufacturing partners like VF Pleasure provide market intelligence, product trend analysis, retail display solutions, and continuous innovation pipelines that help distributors identify growth opportunities, enter new markets, and maintain competitive advantages against emerging competitors.

Diving Deeper Into Manufacturer Growth Support

The most successful distributor-manufacturer relationships transcend basic transaction models. As a manufacturer committed to distributor success, we've developed systematic approaches to supporting business growth beyond simply producing products.

Market intelligence sharing creates mutual value. Our position as a manufacturer serving multiple markets provides visibility into emerging trends across regions. We regularly conduct trend analysis workshops with distribution partners, sharing insights that inform both product development and marketing strategies. This collaboration helped one Canadian distributor identify a growing category six months before their competitors, establishing early market leadership.

Product line strategy development optimizes your offering. We work with distributors to analyze their current portfolio against market opportunities, identifying both gaps and redundancies. This process helped a UK distributor consolidate their product range by 30% while increasing sales by focusing resources on their most profitable and distinctive products.

Retail merchandising support bridges the gap between manufacturing and sell-through. Our team develops custom display solutions, training materials, and point-of-sale assets that help products stand out in retail environments. These resources have proven particularly valuable for distributors entering new retail channels where category presentation significantly impacts sales performance.

Marketing asset development saves distributors significant time and expense. We provide professional photography, product videos, feature highlights, and technical specifications that distributors can integrate into their marketing materials. These assets helped one online distributor reduce their content creation costs by over 40% while improving product presentation quality.

Regulatory guidance navigates increasingly complex compliance requirements. Our experience with regulations across multiple markets helps distributors avoid compliance issues that could restrict product distribution. This support proved crucial for several European distributors adapting to changing EU regulations that might otherwise have required costly product modifications or recertification.

Innovation pipeline sharing allows forward planning. We provide distribution partners with visibility into our product development roadmap, helping them plan future assortment updates and marketing campaigns. This collaborative approach has helped numerous distributors maintain market freshness without the unpredictability that often challenges retail planning.

Co-development opportunities accelerate market differentiation. Beyond standard custom manufacturing, we engage in true co-development with strategic distribution partners, combining our technical expertise with their market knowledge. This approach created breakthrough products for several distributors who now enjoy market exclusivity on innovations their competitors cannot easily replicate.

The most strategic manufacturer-distributor relationships involve regular business reviews focused on growth opportunities, competitive challenges, and continuous improvement. These structured discussions move beyond operational issues to address fundamental business strategy, creating alignment that benefits both parties through sustainable growth.

Conclusion

Partnering with VF Pleasure gives sex toys distributors a competitive edge through quality manufacturing, custom product development, comprehensive support, and logistics excellence that builds profitable, sustainable adult product businesses in today's challenging market.