Worried about what's really inside that adult toy? Unsafe materials can cause infections, allergic reactions, and serious health issues. Your intimate health deserves better than questionable manufacturing practices.

Body-safe adult toys must use non-porous, phthalate-free materials like medical-grade silicone, borosilicate glass, or 316L stainless steel. Quality manufacturers follow FDA guidelines, conduct biocompatibility testing, and maintain ISO 10993 certifications for biological evaluation of medical devices.

I've been in this industry for 15 years, and the transformation in safety standards has been remarkable. When I first started VF Pleasure, the market was flooded with toys containing dangerous chemicals. I remember testing products that made our lab technicians cringe. Today, at our facilities in Dongguan, we refuse to work with anything that doesn't meet the highest safety standards. It's not just about regulations - it's about the people who trust our products with their most intimate moments.

What Materials Should You Absolutely Avoid?

Confused by marketing claims about "safe" materials? Some manufacturers use clever wording to hide dangerous substances. Knowing what to avoid can literally protect your health and your customers' wellbeing.

Never use toys containing phthalates, PVC, rubber, or jelly materials. These can cause chemical burns, allergic reactions, and long-term health issues. Always verify material safety certificates and avoid products with strong chemical odors or oily surfaces.

In my early days as an adult toy manufacturer, I encountered suppliers pushing cheap PVC and jelly materials. The profit margins looked attractive until I understood the health risks. Phthalates, commonly found in cheap toys, are endocrine disruptors linked to hormonal imbalances and reproductive issues. At our sex toys factory, we've completely eliminated these materials from our supply chain. When working with OEM adult toys manufacturer partners, I always emphasize material safety first. Jelly materials might feel soft and appealing, but they're porous breeding grounds for bacteria that can't be properly sterilized. Rubber contains proteins that can trigger severe allergic reactions. TPE (thermoplastic elastomer) is better than jelly but still porous and can degrade over time. For our custom sex toys and private label sex toys, we exclusively use food-grade platinum silicone, borosilicate glass, and medical-grade ABS plastic. These materials are non-porous, hypoallergenic, and can withstand proper cleaning. When customers like Felle Reynolds evaluate products, material safety is always their top priority because they understand that one health incident can destroy a brand's reputation overnight.

| Material Type | Safety Level | Porosity | Sterilizable | Common Issues |

|---|---|---|---|---|

| Medical Silicone | Excellent | Non-porous | Yes | None when quality |

| Borosilicate Glass | Excellent | Non-porous | Yes | Breakage risk |

| 316L Steel | Excellent | Non-porous | Yes | Weight/coldness |

| ABS Plastic | Good | Non-porous | Yes | Can scratch |

| TPE | Fair | Semi-porous | No | Bacterial growth |

| PVC/Jelly | Poor | Porous | No | Chemical toxicity |

How Do You Verify Manufacturing Quality and Testing?

Overwhelmed by technical specifications and testing protocols? Quality verification isn't just paperwork - it's your guarantee that products won't harm users. Smart buyers know exactly what documentation to demand.

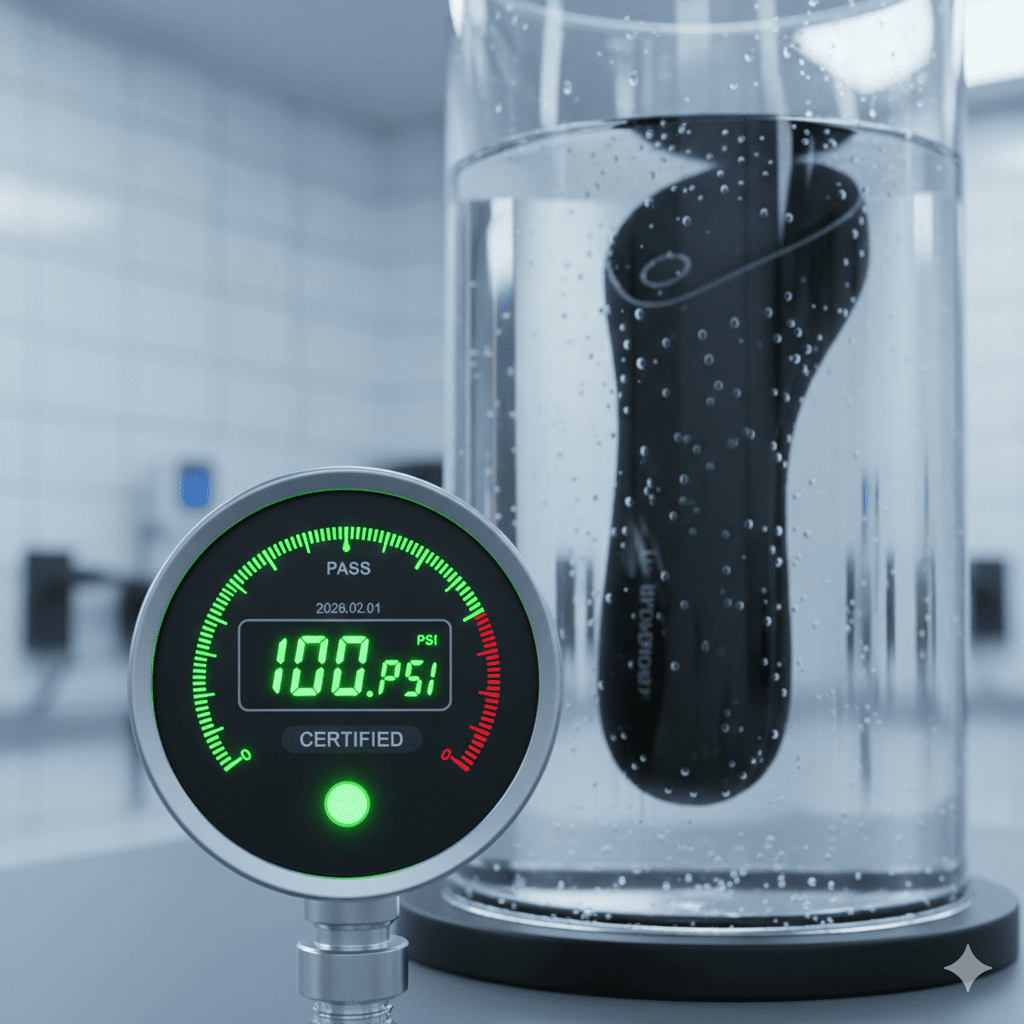

Require biocompatibility testing per ISO 10993 standards, material safety data sheets (MSDS), and third-party laboratory reports. Quality manufacturers provide batch-specific testing results, maintain clean room facilities, and follow pharmaceutical-grade quality control processes.

Quality verification has become incredibly sophisticated since I started in this business. At our Shenzhen R&D center, we maintain partnerships with accredited testing laboratories that specialize in medical device evaluation. Every batch of custom vibrators and female sex toys undergoes rigorous testing protocols. We test for cytotoxicity, skin sensitization, and irritation using internationally recognized methods. Our vibrator factory maintains detailed records of every component's origin and testing history. For wholesale adult toys, we provide complete documentation packages including material certificates, biocompatibility reports, and manufacturing records. The testing process includes checking for heavy metals, volatile organic compounds (VOCs), and phthalate content. We also conduct accelerated aging tests to ensure materials remain stable over time. Electrical safety testing for motorized products follows IEC standards for personal care devices. When evaluating adult toy suppliers, always ask for recent test reports, not just certificates. Legitimate manufacturers can provide batch-specific documentation and explain their testing protocols in detail. They should also maintain traceability systems that can track any component back to its source. This level of quality control might seem excessive, but it's absolutely necessary in an industry where product safety directly impacts intimate health.

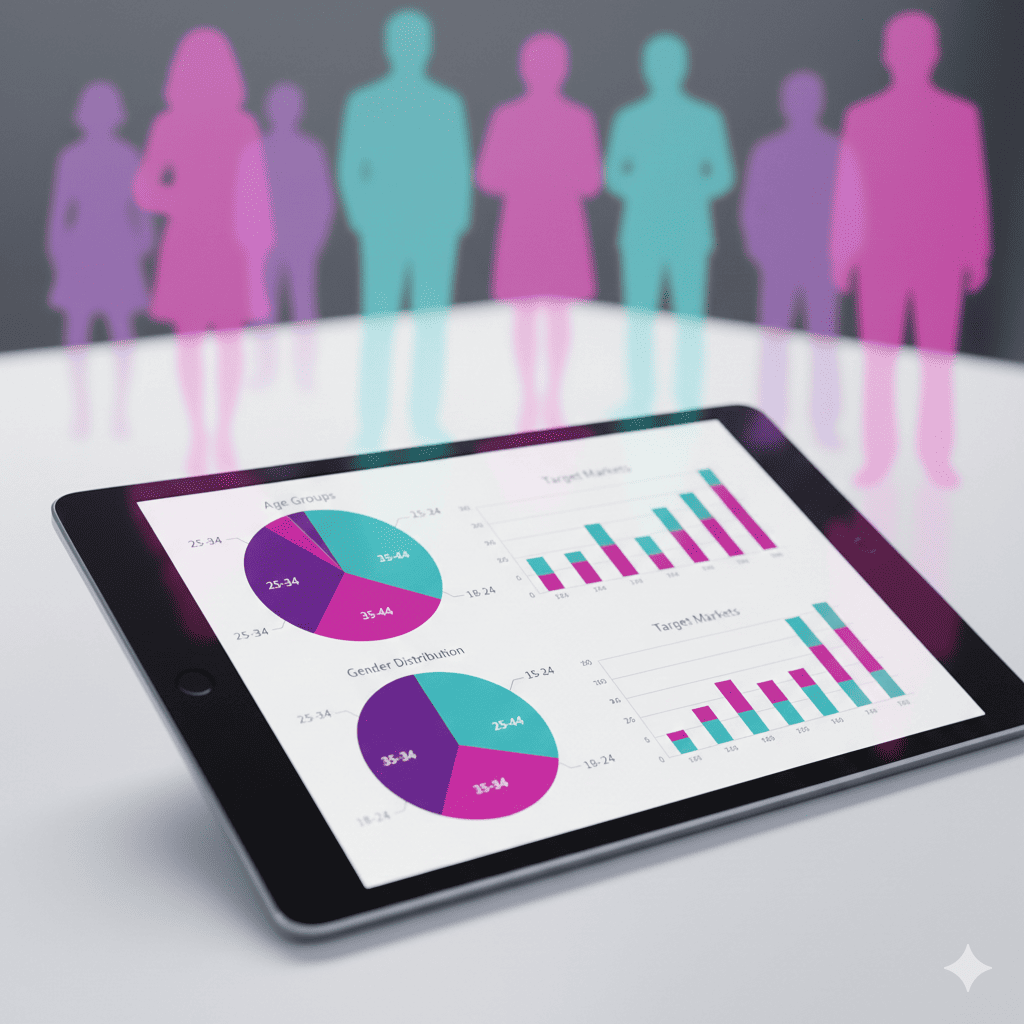

What Certifications Actually Protect Consumers?

Drowning in alphabet soup of certifications? Not all certifications are created equal. Understanding which ones actually matter can help you choose products that prioritize real safety over marketing fluff.

Look for ISO 10993 biocompatibility certification, FDA registration numbers, CE marking with notified body numbers, and RoHS compliance. Avoid manufacturers who can't provide specific certification numbers or rely solely on supplier declarations.

The certification landscape can be confusing, and unfortunately, some manufacturers exploit this confusion. In my experience managing adult toys factory operations, I've learned which certifications actually protect consumers versus which ones are just marketing. ISO 10993 is the gold standard for biological evaluation of medical devices and applies directly to intimate products. This comprehensive standard covers cytotoxicity, sensitization, irritation, and systemic toxicity testing. At VF Pleasure, all our thrusting sex toys and couples toys meet these standards. CE marking is mandatory for European markets, but only CE marks with four-digit notified body numbers indicate proper assessment. Self-declared CE marks are essentially worthless. FDA registration doesn't mean FDA approval, but it does indicate the manufacturer has proper quality systems and facility registration. RoHS compliance ensures products don't contain restricted heavy metals like lead, mercury, or cadmium. For male adult toys with electronic components, FCC certification ensures electromagnetic compatibility. REACH compliance is crucial for EU markets and covers chemical safety extensively. When working with OEM sex toys factory partners, always verify certification numbers directly with issuing bodies. Legitimate certifications can be validated online through official databases. Beware of manufacturers who provide only photocopies or refuse to share certification numbers. Investment in proper certifications might increase costs, but it's essential insurance against legal liability and customer safety issues.

How Do Manufacturing Processes Impact Safety?

Curious about what happens inside the factory walls? Manufacturing processes can contaminate even the safest materials. Understanding production methods helps you identify manufacturers who truly prioritize safety throughout their operations.

Safe manufacturing requires clean room environments, dedicated production lines, proper curing processes for silicone, and contamination prevention protocols. Quality manufacturers maintain separation between different material types and follow pharmaceutical-grade hygiene standards.

Manufacturing process control is where many suppliers fail, even when using quality materials. Our Dongguan facilities operate under pharmaceutical-grade cleanliness standards because contamination can occur at any production stage. For custom adult toys, we maintain separate production lines for different materials to prevent cross-contamination. Silicone curing is particularly critical - improper curing can leave unreacted chemicals that cause skin irritation. Our platinum-cure silicone process requires precise temperature and time controls. We use only platinum catalysts, never tin-based systems that can leave harmful residues. For bulk sex toys production, we implement strict material handling protocols including sealed storage systems and environmental controls. Workers wear protective equipment and follow hygiene procedures similar to food processing facilities. Quality control checkpoints throughout production catch issues before they reach finished products. Our sex toy wholesale clients depend on this consistency. Each production run includes witness samples that undergo full testing protocols. We also maintain detailed batch records that enable complete traceability if issues arise. For electronic components in products like sucking vibrator exporter models, we use lead-free solder and conformal coatings to prevent chemical leaching. The investment in proper manufacturing infrastructure is substantial, but it's the only way to guarantee consistent safety across thousands of products.

What Role Does Packaging Play in Product Safety?

Overlooking packaging in your safety evaluation? Poor packaging can contaminate even the safest products during storage and shipping. Smart manufacturers understand that safety extends beyond the factory floor to your customer's hands.

Safe packaging must be non-reactive, provide barrier protection, and maintain sterility during shipping. Quality manufacturers use pharmaceutical-grade packaging materials, avoid PVC films, and include proper storage instructions and safety information.

Packaging safety is often overlooked, but it's crucial for maintaining product integrity from factory to consumer. At VF Pleasure, we've invested heavily in packaging research because we've seen quality products contaminated by poor packaging choices. For our personalized sex toys and white label sex toys, we use only medical-grade packaging materials. PVC packaging films can transfer phthalates to products during storage, especially in warm conditions during shipping. We use polyethylene or PET films that are chemically inert and won't interact with silicone products. Our sealing processes create barrier protection against moisture, dust, and other contaminants. For premium dildo exporter products, we include desiccant packets and oxygen absorbers when necessary. The packaging design must also protect against physical damage that could compromise product safety. Sharp edges from broken packaging can create injury hazards. We conduct drop tests and compression tests to ensure packaging integrity throughout the supply chain. Storage instructions are critical - proper temperature and humidity ranges prevent material degradation. For wholesale dildos and bulk shipments, we use moisture barrier bags and provide detailed storage guidelines. Our packaging also includes comprehensive safety information, cleaning instructions, and material disclosures. When evaluating manufacturers, examine their packaging materials and ask about storage stability testing. Quality packaging might seem like an unnecessary cost, but it's essential for maintaining the safety investments made in materials and manufacturing.

Conclusion

Body-safe adult toy manufacturing requires comprehensive attention to materials, processes, testing, and compliance. Invest in manufacturers who prioritize safety as much as performance and profitability.