Struggling to bring a unique product idea to a competitive market? Turning a concept into a physical product on the shelf can feel complex, but it's a clear path with the right partner.

The step-by-step process for developing private label adult products involves five key stages: concept and market research, design and material selection, prototyping and testing, mass production and quality control, and finally, packaging and logistics. Partnering with an experienced manufacturer simplifies this journey significantly.

I've spent 15 years in this industry, helping people just like you navigate this exact process. I've seen brilliant ideas get stuck and simple ones become best-sellers. The difference is almost always in having a clear, step-by-step plan. Let me walk you through how we at VF Pleasure turn a simple idea into a shelf-ready product. It's a journey we've perfected, and understanding it will give you the confidence to start.

What’s the First Step in Creating a Custom Sex Toy?

Have a great idea but not sure if it will sell? Market research is your first, most crucial step. It helps you see what customers want and where your idea fits in.

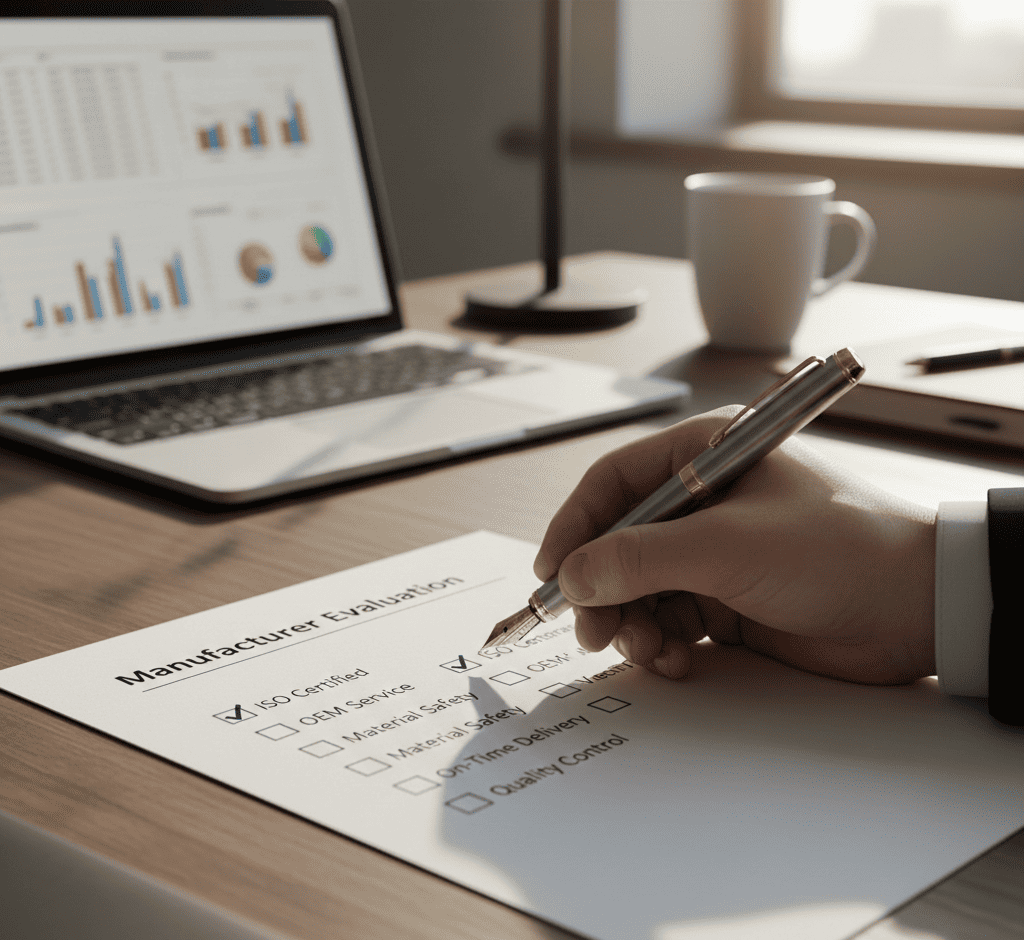

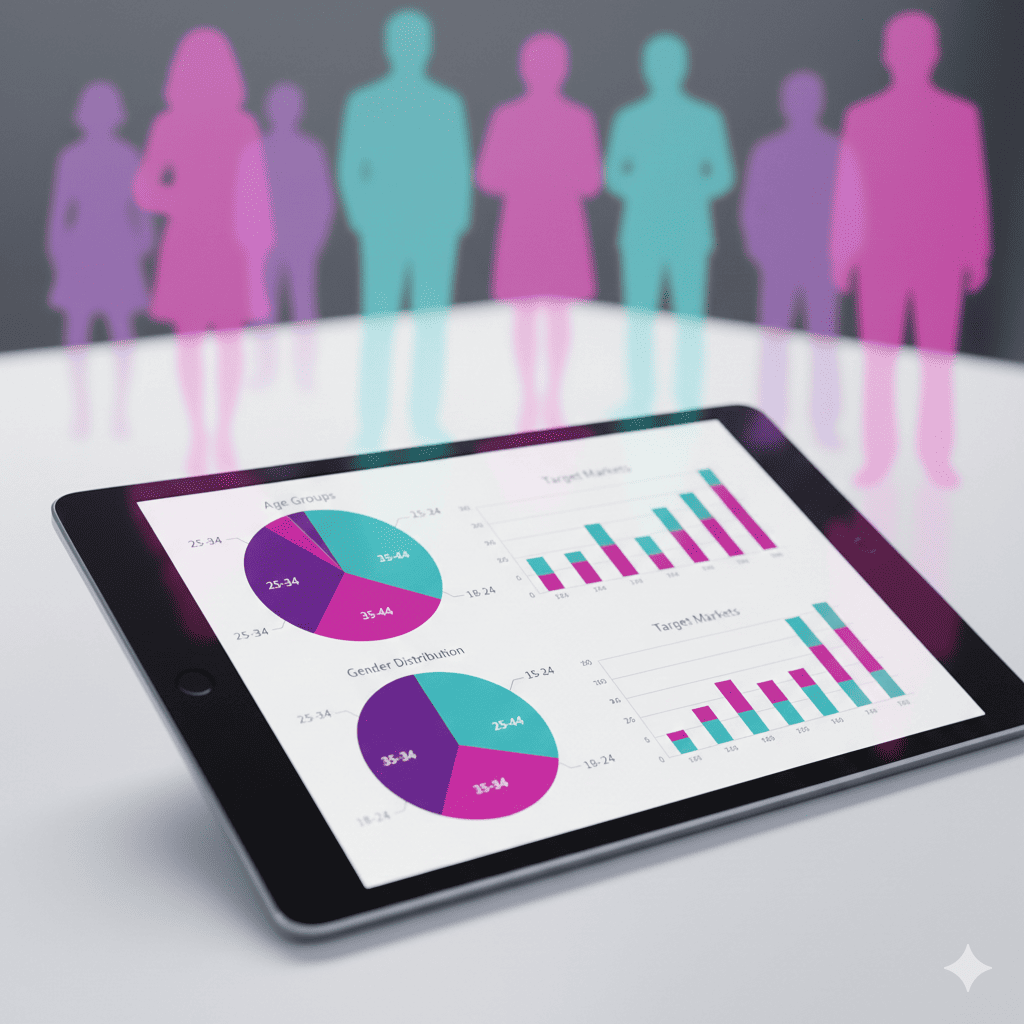

The first step in creating a custom sex toy is combining market research with concept development. This involves identifying your target audience, analyzing trends, and creating a detailed design brief that outlines the product's function, features, and desired materials before approaching a sex toy factory.

I remember a client, let's call him David, who came to us with an idea for a highly specialized thrusting sex toy. He was passionate, but passion alone doesn't guarantee sales. The first thing we did together was dive deep into market research. We looked at what was already selling in the adult sex toys wholesale1 market and identified a gap. This research phase is non-negotiable; it turns a guess into a calculated business decision. Based on these insights, we refined his concept, focusing on a unique feature that no other product offered. We detailed everything in a design brief, which is like a blueprint for the project. This document guides a full service adult toy2 manufacturer like us through your vision. We discuss materials, from body-safe, food-grade platinum silicone to ABS plastic, ensuring the final product is exactly what you, and more importantly, your customers, are looking for. It’s this foundational work that prevents costly mistakes later on.

| Material | Key Benefits | Best For |

|---|---|---|

| Medical-Grade Silicone | Body-safe, hypoallergenic, non-porous, easy to clean, durable. | Premium and luxury vibrators, dildos, and couples toys where quality is paramount. |

| ABS Plastic | Rigid, smooth, affordable, good for complex electronic housing. | Housings for vibrators, budget massagers, and toys with internal mechanisms. |

| Glass | Non-porous, hypoallergenic, can be heated or cooled. | Niche and premium dildos, plugs, and aesthetic-focused toys. |

| TPE (Thermoplastic Elastomer) | Very soft, flexible, lower cost. | Budget-friendly toys or products where a "realistic" texture is desired. Must ensure it's phthalate-free. |

How Does Prototyping and Manufacturing Actually Work?

Your design looks perfect on paper, but will it work in real life? Prototyping is how you find out. It’s where your idea becomes something you can actually hold and test.

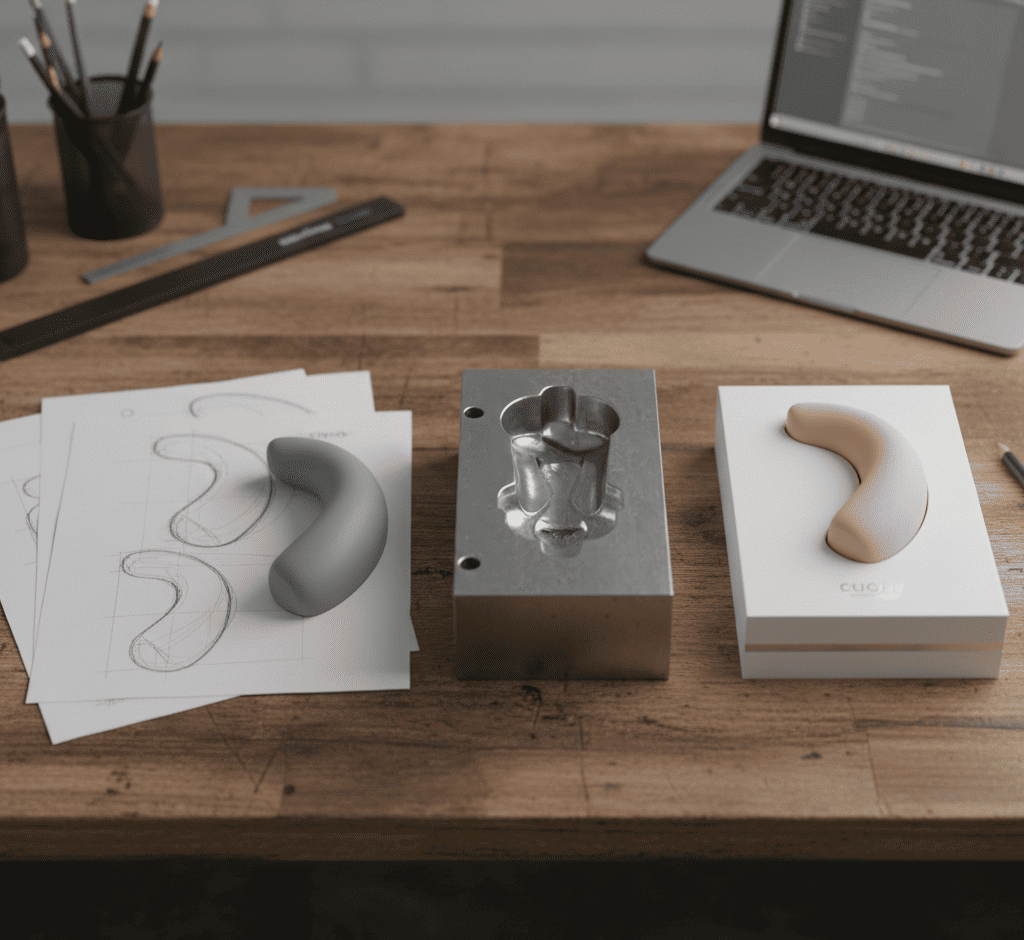

After finalizing the design brief, the process moves to prototyping and then mass production. Prototyping involves creating initial models to test the design's form and function, while manufacturing scales up production using methods like injection molding for precision and efficiency.

This is my favorite part of the process. It's where the magic really happens. At our adult toys factory in Dongguan, our design team takes your brief and creates 3D models. From there, we might use CNC machines or 3D printers to create a "looks like" or "works like" prototype.This is a critical feedback loop. You get to touch and feel the product, test its ergonomics, and make sure the function is perfect before committing to expensive tooling. It's not uncommon to go through a few revisions. Once you approve the prototype, we move to create the steel molds for mass production. With our 5-10 production lines, we can then begin manufacturing. Whether you need custom vibrators, wholesale dildos, or want to become a dildo supplier, this is the stage where your inventory is created. As a seasoned sex toy manufacturer china, we've streamlined this to be as efficient as possible, turning your approved design into thousands of units ready for the next step.

What Happens After Production to Get Products on Shelves?

Your products are made, but they aren't ready for customers yet. The final steps are just as important as the first. Quality control, packaging, and shipping are what protect your brand's reputation.

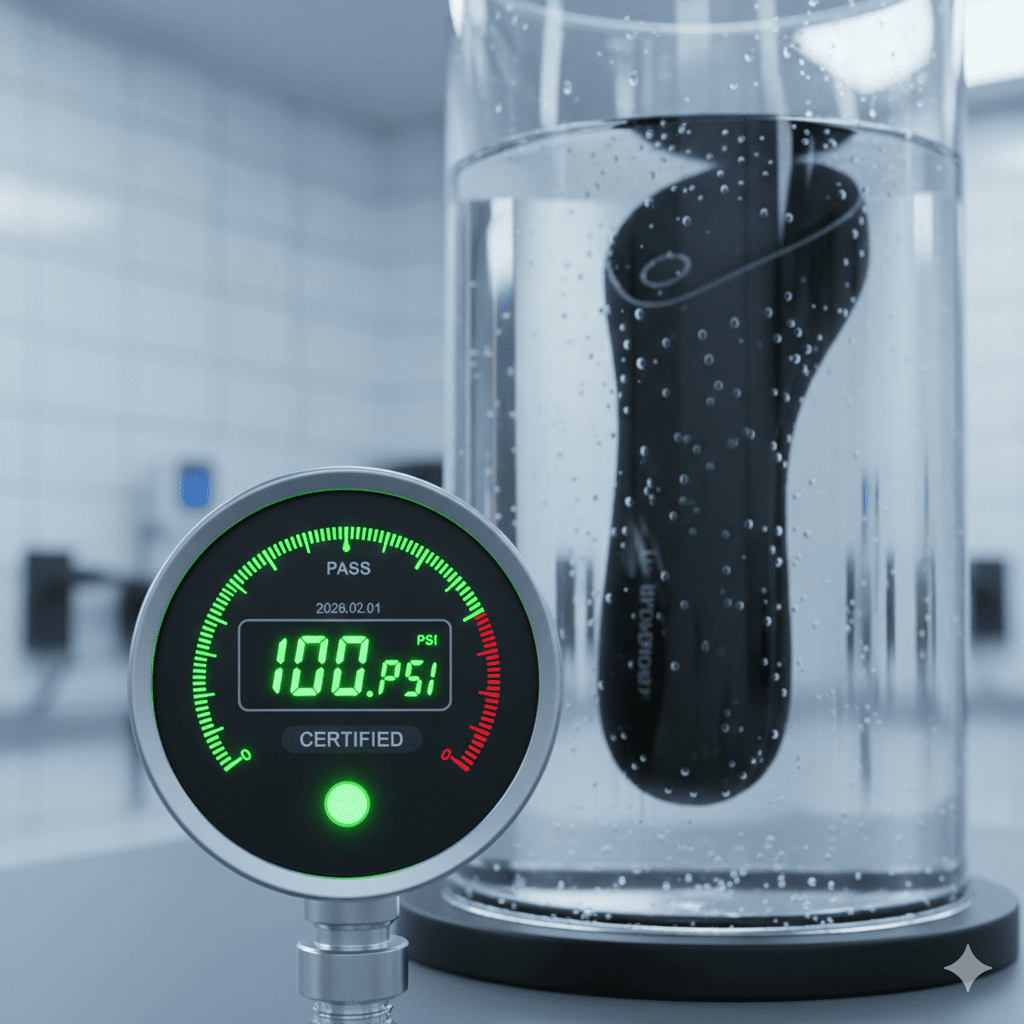

After mass production, the final steps are quality control (QC), branding and packaging, and logistics. Rigorous QC checks ensure every product meets safety and performance standards.Packaging protects the product and builds your brand, while logistics handle getting the products to you or your distributors.

Think of this final phase as the home stretch. Every single unit that comes off our line undergoes strict quality control.We test for everything—material safety, durability, and electronic function.A faulty product can ruin a brand's reputation, and as your adult toy supplier3, we take that responsibility very seriously. Next, we work with you on packaging. For a private label sex toys4 brand, the box is more than just protection; it's your brand's first impression. We can help you design unique, eye-catching packaging that reflects your identity. Finally, we handle the logistics. Whether you are selling wholesale adult toys or need bulk sex toys shipped internationally, we manage the complexities of customs and delivery. We ensure your products arrive safely and discreetly, ready for your warehouse or retail shelves. From a single idea to a product in your customer's hands, we are there every step of the way, offering a complete OEM/ODM solution.

Conclusion

Bringing a private label product to life is a clear, manageable process with the right manufacturing partner. From research to shipping, we can guide you through every single step.

-

Exploring this link will provide insights into market trends and help you understand the competitive landscape. ↩

-

This resource will clarify the benefits of working with a full service manufacturer, ensuring your product meets market demands. ↩

-

Explore this link to understand how to select a reliable adult toy supplier that ensures quality and safety. ↩

-

Discover strategies for building a strong private label sex toys brand that stands out in the market. ↩