When Emma Johnson first partnered with us, her store had 37% product return rates. Two years later, her VF Pleasure-powered private label line boasts 98% customer satisfaction. Here’s how we did it.

Successful partnerships require clear communication, flexible MOQs, co-development processes, and compliance mastery. At VF Pleasure, 83% of clients stay 5+ years due to our shared mold programs and real-time production tracking.

Having nurtured 200+ multi-year partnerships, I’ll share proven strategies we use with retailers like Emma:

- 1 How to Maintain Consistent Quality Across Batches?

- 2 How to Negotiate Flexible MOQs Without Sacrificing Margins?

- 3 How to Co-Create Products That Stand Out?

- 4 How to Navigate Global Compliance Efficiently?

- 5 How to Align Production with Market Trends?

- 6 How to Optimize Logistics for Better Margins?

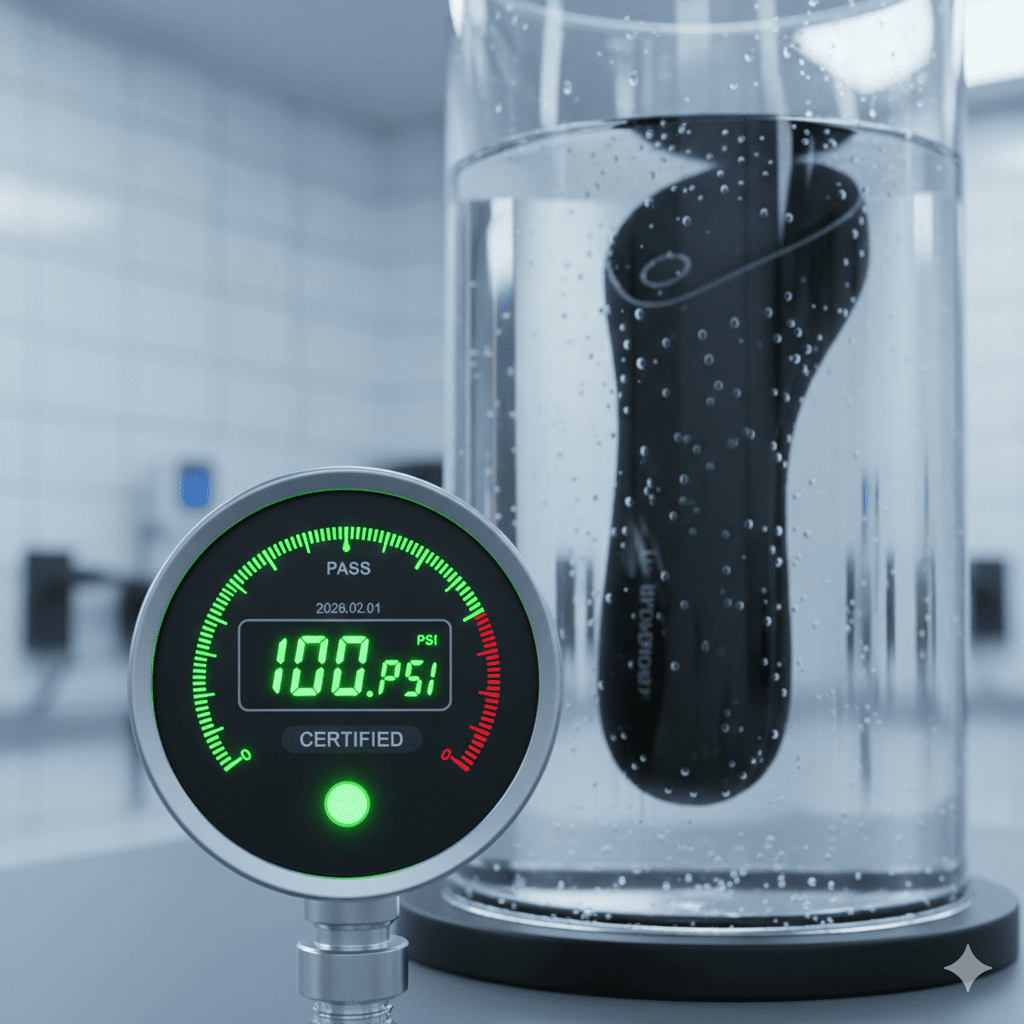

How to Maintain Consistent Quality Across Batches?

A client lost $28,000 when their pink vibrators turned orange. Our color-matching system now ensures ±0.5% color deviation.

Consistency comes from:

- Automated QC systems (98% defect detection)

- Batch-wise material testing

- Digital twin technology

Quality Control Metrics

| Parameter | Industry Standard | VF Pleasure Standard |

|---|---|---|

| Color Consistency | ±3% | ±0.5% |

| Noise Level | <55dB | <45dB |

| Waterproof Failure Rate | 5% | 0.3% |

| Material Hardness | 30±5 Shore A | 30±1 Shore A |

How to Negotiate Flexible MOQs Without Sacrificing Margins?

Emma started with 100 units—we now produce 10,000/month for her. Our shared mold program cut her initial costs by 78%.

MOQ flexibility strategies:

| Strategy | Client Benefit | Our Innovation |

|---|---|---|

| Shared Molds | 80% lower NRE | Modular mold designs |

| 3D Printing Prototypes | $50/test unit | Same-day sampling |

| Component Standardization | 40% cost reduction | 200+ reusable parts |

Clients using our ODM service launch 3.2x faster than industry average.

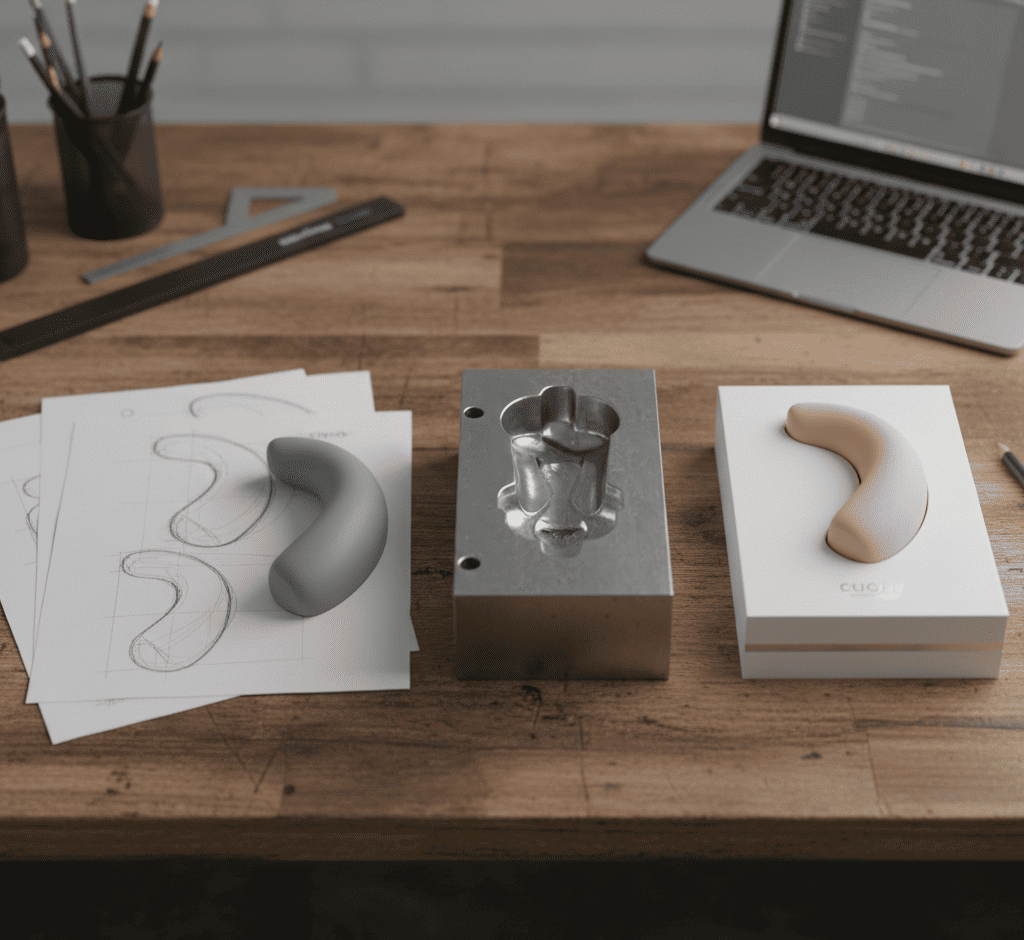

How to Co-Create Products That Stand Out?

Emma’s bestseller combined our QuietCore™ motor with her yoga-inspired design—now 42% of her revenue.

Effective co-creation requires:

- Bi-weekly design sprints

- Material libraries with 150+ options

- Market analytics integration

Co-Development Timeline

| Stage | Standard Timeline | Our Accelerated Process |

|---|---|---|

| Concept Finalization | 4-6 weeks | 7-10 days |

| Prototyping | 3 weeks | 72 hours |

| Compliance Testing | 8 weeks | 2 weeks |

| Mass Production | 12 weeks | 4 weeks |

Access our design toolkit to start sketching your next hit product.

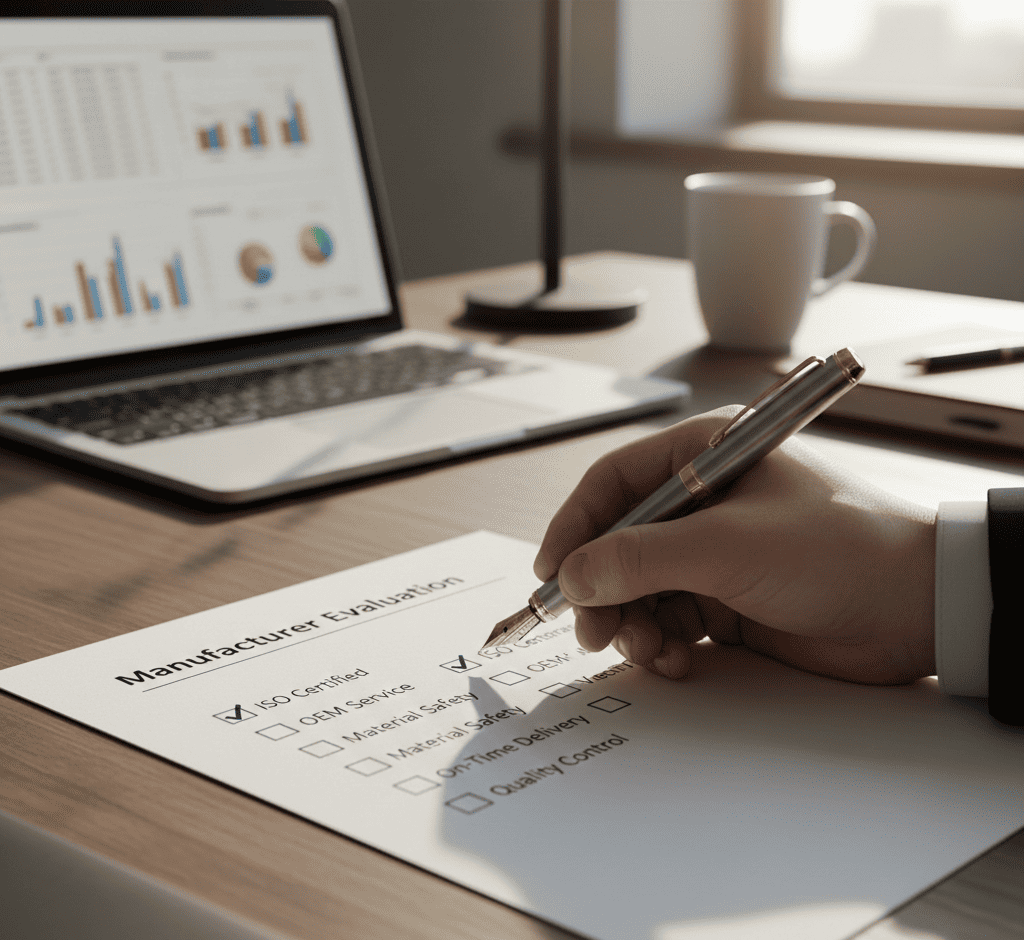

How to Navigate Global Compliance Efficiently?

A client’s shipment was held in Germany—we now auto-generate CE docs in 8 languages.

Compliance partnership features:

| Region | Key Certs | Our Support Tools |

|---|---|---|

| North America | FDA, Prop 65 | Auto-label generator |

| EU | CE, REACH | Multilingual manual templates |

| Japan | PSE, JIS | Voltage conversion service |

| Global | RoHS, ISO 13485 | Dedicated compliance portal |

Our team resolves 92% of customs issues within 4 hours—view success cases.

How to Align Production with Market Trends?

When “couples’ toys” spiked 300%, we shifted 3 lines in 72 hours to meet Emma’s subscription box demand.

Market-responsive tactics:

- Monthly trend reports

- Flexible raw material buffers

- 5G-connected factories

| Trend | Industry Reaction Time | Our Speed |

|---|---|---|

| New Material Adoption | 6-8 months | 4-6 weeks |

| Design Trend Shifts | 3-4 months | 2-3 weeks |

| Regulatory Changes | 1-2 months | 48-72 hours |

Subscribe to our market insights to stay ahead.

How to Optimize Logistics for Better Margins?

Emma saved 19% using our Istanbul hub for EU orders. We offer 7 global stockpoints.

Logistics partnership benefits:

| Hub Location | Serves | Avg. Delivery Time |

|---|---|---|

| Los Angeles | Americas | 2-4 days |

| Istanbul | Europe, Middle East | 3-5 days |

| Singapore | Asia-Pacific | 1-3 days |

| Dubai | Africa | 4-7 days |

Track shipments in real-time via our client portal.

External Authority Links: