Most procurement managers get burned by suppliers who promise everything but deliver disappointment. You're not alone if you've experienced motor failures, inconsistent performance, or hidden cost escalations when sourcing thrusting vibrators from China.

After 15 years leading VF Pleasure's operations in DongGuang, I've found that successful thrusting vibrator partnerships require balancing three critical factors: genuine low MOQ capabilities, fast prototyping expertise, and motor specification mastery that most suppliers simply don't possess.

If you're tired of suppliers who overpromise and underdeliver, you need to understand what separates legitimate manufacturers from order-takers in this complex product category.

What Makes Low MOQ Thrusting Vibrator Manufacturing Actually Sustainable?

The promise sounds too good to be true because it usually is. Every week, I see procurement managers fall for suppliers advertising MOQs of 50 or even 25 pieces for thrusting products.

True low MOQ capability for thrusting vibrators requires exceptional production efficiency, established material sourcing relationships, and motor inventory management that most suppliers lack. Legitimate minimums start at 100 pieces for established designs, with custom development requiring 300-500 pieces.

The Hidden Economics Behind Sustainable Low MOQs

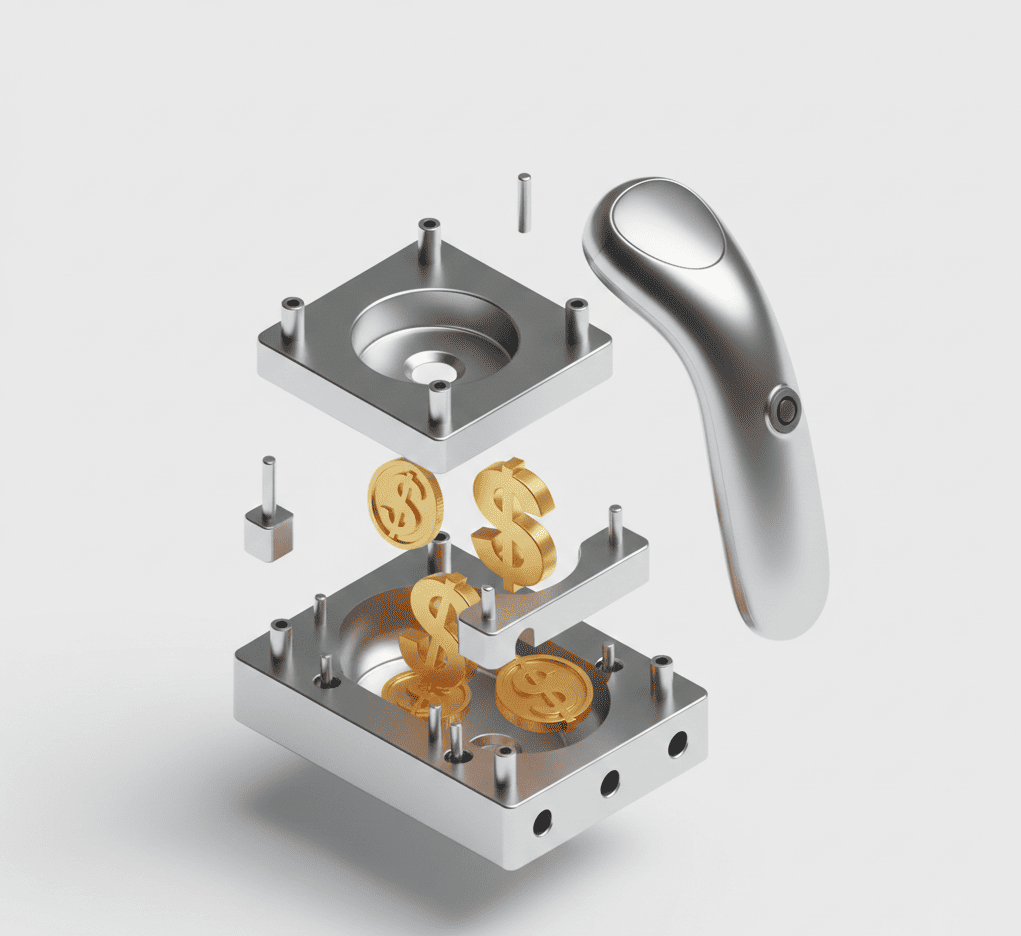

At VF Pleasure, we maintain custom sex toys factory capabilities that allow genuine low minimums through three key investments most suppliers avoid.

First, we stock specialized motors in multiple torque ranges. Most adult toy manufacturers rely on generic motors ordered per project. We maintain inventory of 12 different thrusting motor specifications, allowing us to fulfill small orders without waiting for motor production runs.

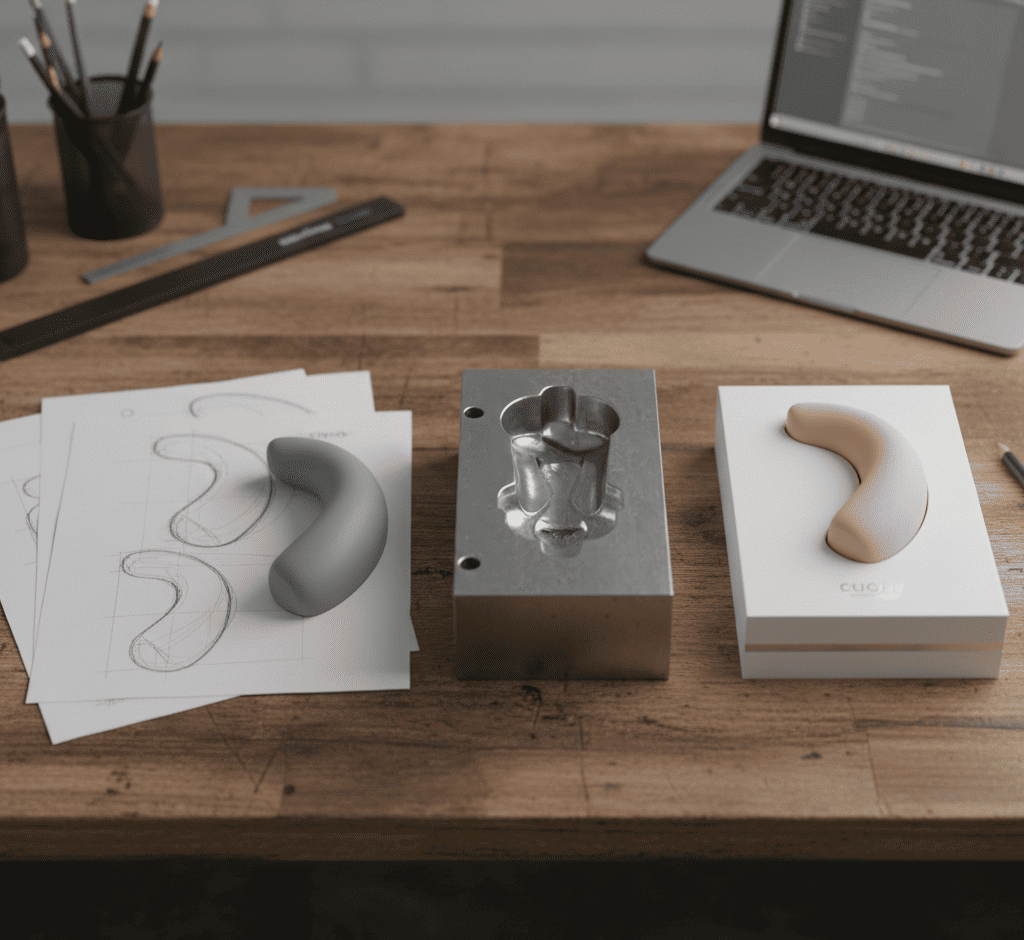

Second, our silicone molding setup accommodates small batches efficiently. We invested in modular tooling systems that eliminate the typical fixed costs associated with small production runs. Traditional suppliers amortize tooling costs across large orders, making small quantities financially unfeasible.

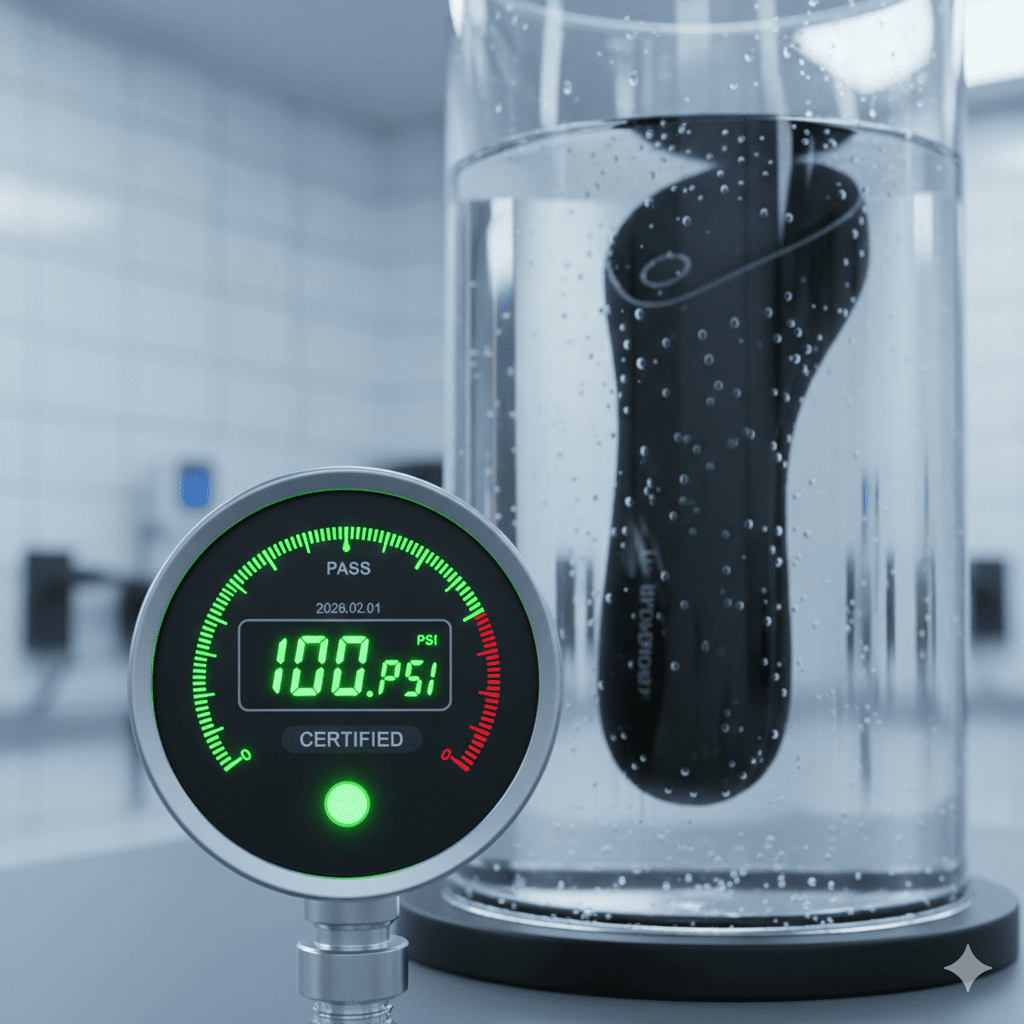

Third, we've developed streamlined quality control processes specifically for thrusting sex toys that maintain standards regardless of quantity. Many suppliers compromise testing protocols on small orders, leading to the quality issues you've probably experienced.

The reality check? If a supplier offers extremely low MOQs without these capabilities, they're either inflating per-unit costs dramatically or cutting corners somewhere in the process.

How Fast Should Thrusting Vibrator Prototyping Actually Take?

Speed matters, but not at the expense of functionality. I've seen too many procurement managers choose suppliers based on unrealistic prototyping timelines, only to receive products with fundamental design flaws.

Professional thrusting vibrator prototyping requires 7-14 days minimum for motor calibration, silicone molding precision, and comprehensive testing phases. Suppliers promising faster turnarounds typically skip critical testing that prevents motor failures in final products.

The Testing Phases That Separate Professional Manufacturers

Our prototyping timeline at VF Pleasure reflects years of R&D investment in understanding what actually matters for thrusting product reliability.

Days 1-3 involve motor specification1 and initial assembly. We test torque delivery, stroke length consistency, and heat generation under various load conditions. Most suppliers skip load testing entirely, leading to motors that fail under normal use conditions.

Days 4-7 focus on silicone molding precision2 and material compatibility. Thrusting mechanisms create unique stress patterns on silicone housings that require specialized compound formulations. We maintain relationships with medical-grade silicone suppliers who understand these requirements.

Days 8-14 involve comprehensive performance testing cycles. We run 500-cycle endurance tests, temperature monitoring, and noise level measurements. This phase identifies the design issues that cause warranty claims later.

The suppliers who promise 3-day prototyping either have pre-made samples (not custom prototypes) or skip the testing phases that ensure your final products actually work reliably.

Why Motor Specification Expertise Matters More Than You Think?

Generic motors kill thrusting vibrator performance faster than any other factor. After working with hundreds of clients, I've learned that motor customization capability directly correlates with long-term product success.

Quality thrusting vibrators require suppliers who modify torque and stroke patterns based on target demographics rather than using one-size-fits-all components. In-house motor customization capabilities separate serious manufacturers from component assemblers.

The Motor Variables That Impact Performance

At our adult toys factory, we customize five critical motor parameters based on your target market requirements.

Torque ratings3 determine penetration force and user satisfaction levels. We adjust torque based on intended user demographics - higher torque for premium products, optimized torque for battery life in budget ranges. Generic motors use fixed torque ratings that rarely match market needs.

Stroke length affects sensation delivery and mechanical reliability. We modify stroke patterns from 15mm for subtle stimulation to 45mm for intense experiences. Most suppliers offer only standard stroke lengths, limiting your product differentiation opportunities.

Speed variability enables better user experience customization. Our motors support 3-12 speed variations with consistent performance across ranges. Standard motors often lose torque at higher speeds, disappointing end users.

Noise levels4 matter more than most suppliers understand. We achieve sub-50dB operation through motor mounting isolation and housing design integration. Cheap suppliers ignore noise optimization, creating products customers won't use discreetly.

Heat management prevents motor damage and user discomfort. We implement thermal protection circuits and heat-dissipating housing designs based on motor specifications. Generic approaches lead to overheating issues and shortened product lifespans.

What Should You Actually Look for in Thrusting Vibrator Suppliers?

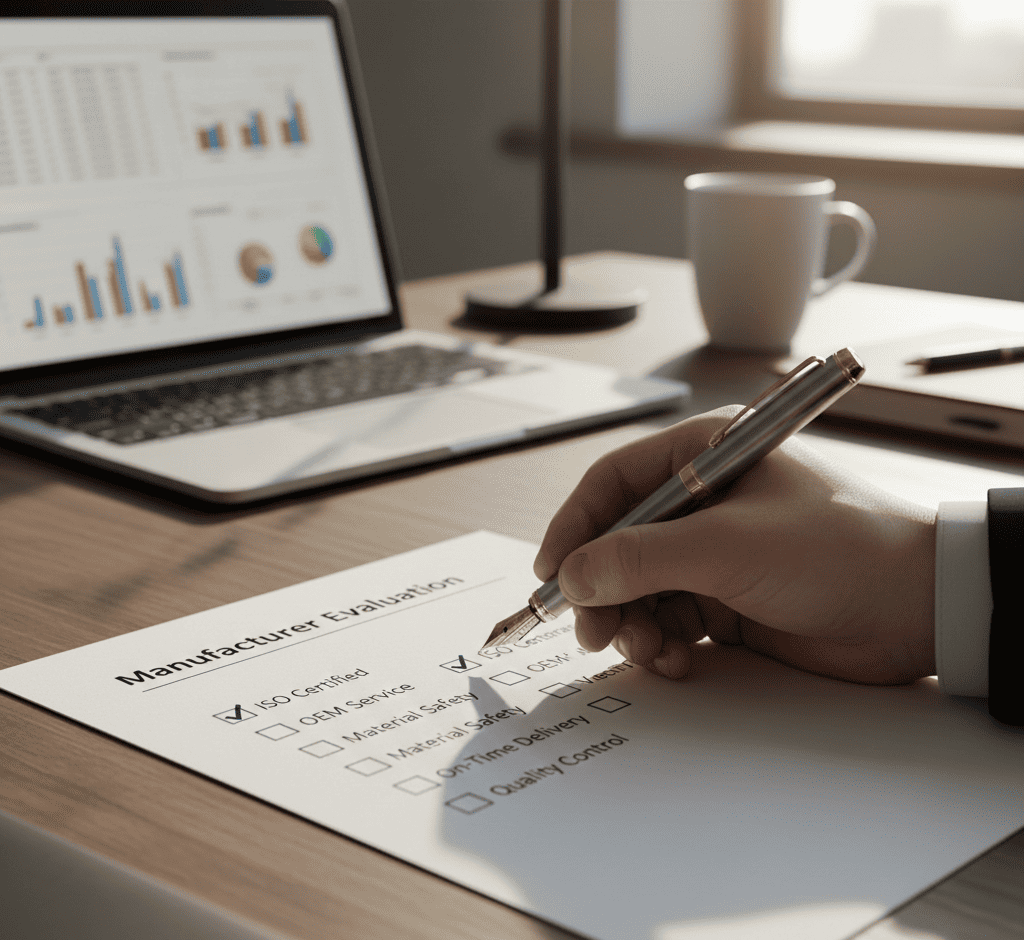

Evaluation criteria matter more than supplier promises. After helping hundreds of brands source successfully, I've identified the questions that reveal genuine capability versus marketing claims.

Ask potential suppliers for motor specification sheets, testing protocols, and prototype timeline breakdowns. Legitimate manufacturers provide detailed technical documentation, while order-takers offer vague assurances and generic product photos.

The Documentation That Reveals True Capability

Request comprehensive testing reports for their existing thrusting products. Professional manufacturers maintain detailed performance data including endurance cycles, failure rates, and warranty statistics. Suppliers who can't provide this data likely don't perform adequate testing.

Examine their OEM adult toys manufacturer credentials and certifications. Look for ISO 134855 medical device quality management, FDA registration numbers, and CE compliance documentation. These certifications require the quality systems necessary for reliable thrusting product manufacturing.

Evaluate their motor customization examples and technical specifications. Ask for torque curves, speed variation data, and noise level measurements across their product range. Suppliers with genuine motor expertise can provide detailed technical discussions about performance optimization.

Review their prototype development process documentation. Professional manufacturers outline each testing phase, timeline expectations, and deliverable specifications. Vague promises about "fast prototyping" without detailed processes indicate shortcuts that compromise quality.

The investment in proper supplier evaluation pays dividends through reduced warranty claims, stronger end-customer satisfaction, and better long-term profitability compared to choosing suppliers based solely on price or speed promises.

Conclusion

Success in thrusting vibrator sourcing requires suppliers who balance genuine low MOQ capabilities, professional prototyping timelines, and motor customization expertise - capabilities that separate legitimate manufacturers from order-takers promising everything but delivering disappointment.

-

Understanding motor specifications is crucial for ensuring product reliability and performance. Explore this link to learn more. ↩

-

Silicone molding precision is vital for product durability. Discover insights on its impact on quality by visiting this resource. ↩

-

Understanding torque ratings is crucial for enhancing user satisfaction and product performance. Explore this link for expert insights. ↩

-

Minimizing noise levels is essential for user comfort and discretion. Discover effective strategies to achieve quieter operations. ↩

-

Learn about ISO 13485 to grasp its significance in ensuring quality management in medical device manufacturing, crucial for safety and reliability. ↩