Your business depends on finding the right manufacturing partner, but glossy brochures often hide disorganized workshops. One wrong choice can destroy your brand reputation and profit margins.

After 15 years operating in Dongguan, I've developed a four-point checklist that separates reliable OEM adult toy factories from risky partnerships. This system focuses on IP security, engineering competence, quality control depth, and operational transparency - the four pillars that determine manufacturing success.

I've seen too many brands get burned by factories that looked perfect on paper. My experience at VF Pleasure taught me that real due diligence goes far deeper than price comparisons and capacity claims.

What IP Security Protocols Should You Demand?

Your designs are your competitive advantage. Losing control of your intellectual property can kill your business overnight.

Demand explicit mold storage protocols and signed NDAs before sharing any design files. Ask directly: "Do you sell client-designed molds on platforms like 1688?" A trustworthy custom adult toys factory will have physical security measures separating your tooling from open-market products.

The Real Cost of IP Theft

I once consulted with a European brand that discovered their exclusive design selling for $3 on Alibaba. The OEM sex toys factory had simply duplicated their mold and started mass production.

This happens more often than you'd think. Many adult toy manufacturers treat client designs as templates for their own product lines. They'll fulfill your order, then use your innovation to undercut you in the market.

Physical Security Measures That Matter

Look for these specific protections:

Segregated Storage Areas1: Your molds should be stored separately from standard production tooling. The factory should show you dedicated spaces with restricted access.

Digital File Protection: Ask about their CAD file storage systems. Professional adult toy factory2 operations use encrypted servers with user-specific access controls.

Employee Training: Staff handling your designs should sign individual NDAs. The factory should have clear protocols about sharing client information.

Audit Trail Documentation: You should receive regular reports showing when your molds are accessed and by whom.

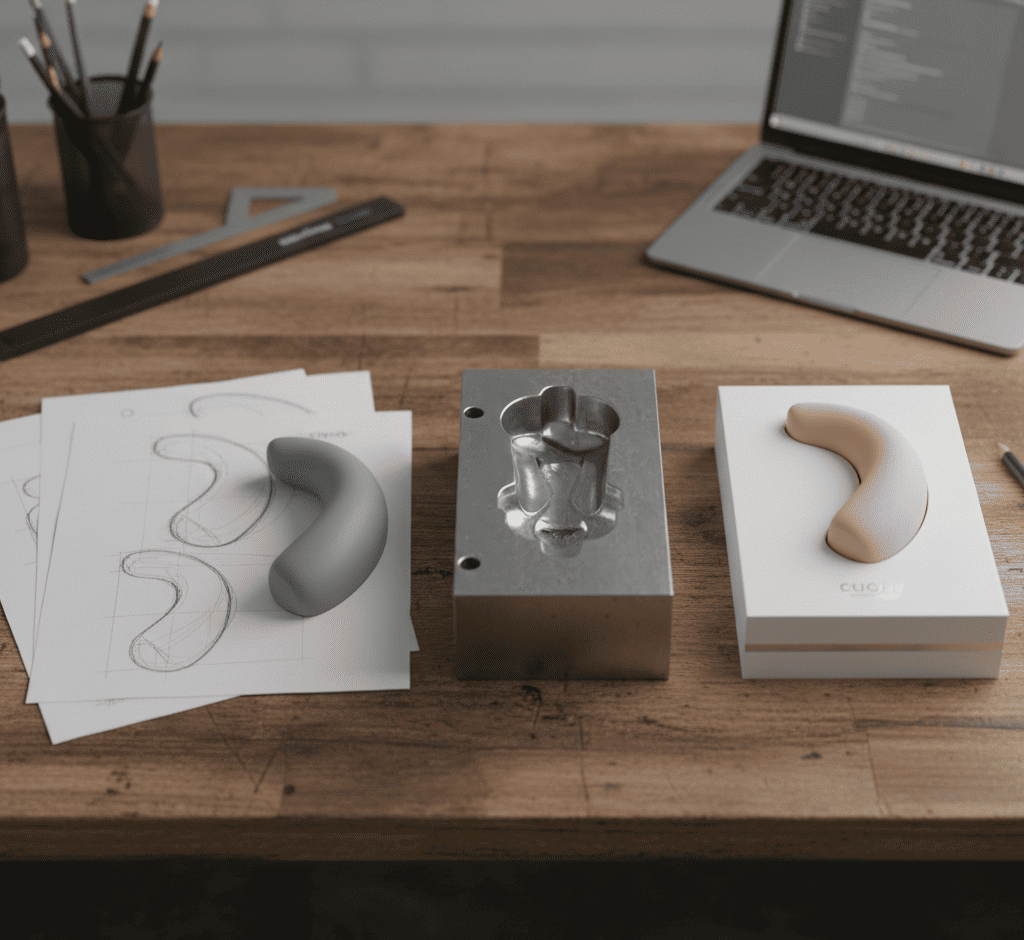

How Can You Spot a Yes-Man Factory?

Engineering pushback is a good sign. Factories that agree to everything without questions usually can't deliver what they promise.

Send a deliberately complex design file as a test. Reliable adult toy suppliers will respond with technical questions and manufacturability concerns. If they say "no problem" instantly, they're probably order-takers, not engineering partners.

The Engineering Red Flags

Real manufacturers ask hard questions. When I review designs at VF Pleasure, we immediately flag potential issues. Here's what genuine engineering feedback sounds like:

Material Compatibility Questions3: "This silicone grade won't bond properly with the ABS housing. Can we adjust the shore hardness?"

Tooling Concerns: "This undercut will require a complex slide mechanism. It'll add $2000 to the mold cost but improve part quality."

Production Efficiency Issues4: "This design requires four-hour cure cycles. We can modify the wall thickness to reduce that by half."

What Real Problem-Solving Looks Like

Professional sex toy manufacturers don't just accept your files. They improve them. We regularly suggest design modifications that reduce costs while maintaining functionality.

For example, a client wanted a complex internal mechanism for their thrusting sex toys. Instead of building exactly what they specified, we proposed a simpler solution that achieved the same result with 40% fewer parts.

Testing Protocols: We simulate stress points using CAD analysis before cutting steel.

Cost Optimization: Our team identifies expensive features that don't add user value.

Regulatory Compliance: We flag potential safety issues that could cause problems in different markets.

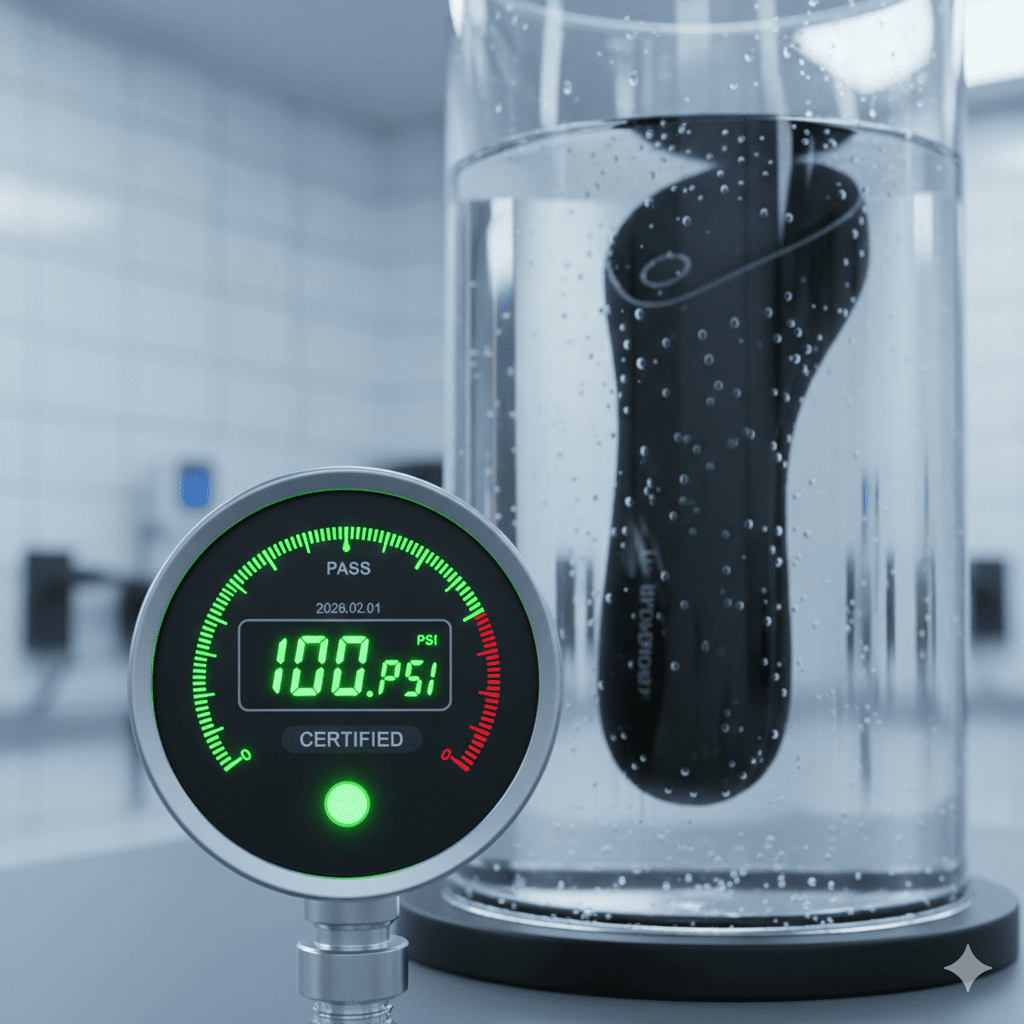

Why Does Quality Control Go Beyond Final Inspection?

Most factories only check finished products. Smart buyers audit the entire supply chain, starting with incoming components.

Ask about IQC (Incoming Quality Control) procedures. Do they test battery aging and motor torque before assembly? Component failures caught after silicone molding become expensive returns that destroy your profit margins.

The Hidden Cost of Poor Component Screening

I learned this lesson the expensive way. Early in my career, we had a batch of vibrators fail after three months. The motors passed final inspection but had marginal bearings that degraded with use.

That single oversight cost us $50,000 in returns and nearly lost a major client. Now, our IQC process tests every component before it enters production.

Component Testing That Actually Matters

Battery Cycle Testing5: We run sample batteries through 500 charge cycles before approving batches. This catches capacity issues that won't show up in basic voltage tests.

Motor Durability Analysis6: Each motor design gets 72-hour continuous operation testing. We measure torque degradation and heat buildup under realistic loads.

Silicone Contamination Screening: Raw silicone batches get tested for heavy metals and volatile compounds. One bad batch can contaminate an entire production run.

Electronic Stress Testing: Circuit boards undergo thermal cycling and vibration testing that simulates years of normal use.

Documentation You Should Demand

Professional wholesale sex toys manufacturers provide detailed test reports:

- Component certificates of analysis

- Incoming inspection checklists

- Process control charts showing consistency trends

- Corrective action reports for any failures

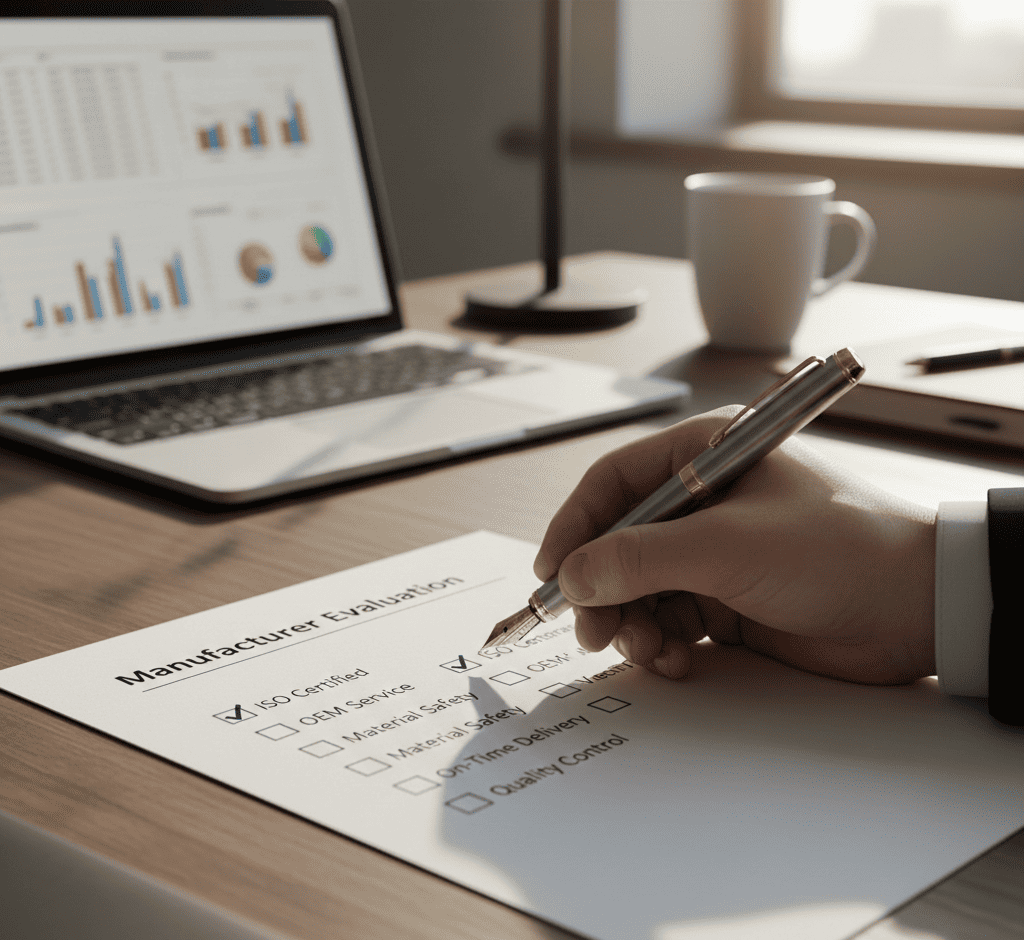

What Transparency Standards Should You Expect?

If a factory won't show you their production line, they're hiding something. Demand video walkthroughs or third-party audits.

Professional OEM adult toys manufacturers welcome facility tours. They understand that transparency builds trust. Factories that hesitate are usually middlemen or have hygiene issues that would concern your customers.

Virtual Auditing That Works

COVID changed how we handle facility visits, but virtual auditing can be just as effective. Here's what I require:

Live Production Walkthroughs: Real-time video calls showing active production lines. This reveals actual working conditions, not staged setups.

Storage Area Documentation: Videos of raw material storage, work-in-progress areas, and finished goods warehouses. You're looking for cleanliness and organization.

Staff Interviews: Brief conversations with floor supervisors and quality technicians. Their knowledge level tells you about training standards.

Equipment Close-ups: Detailed shots of molding machines, testing equipment, and packaging lines. Modern equipment suggests investment in quality.

Third-Party Validation

Consider hiring independent auditors for major partnerships. Organizations like SGS and Bureau Veritas offer specialized adult products facility audits.

These audits check:

- ISO certification compliance

- Worker safety protocols

- Environmental impact procedures

- Quality management systems

Red Flag Behaviors: Factories that refuse audits, delay scheduling, or restrict access to certain areas.

Green Light Indicators: Open communication, detailed documentation, and proactive compliance updates.

Conclusion

Your OEM partner choice determines your brand's success. Focus on IP security, engineering competence, comprehensive quality control, and operational transparency to find manufacturers who'll grow with your business.

-

Understanding the significance of segregated storage areas can help you safeguard your intellectual property effectively. ↩

-

Exploring this link will provide insights into selecting a reliable adult toy factory, ensuring your designs are protected. ↩

-

Understanding material compatibility is crucial for successful product design and manufacturing, ensuring durability and performance. ↩

-

Exploring production efficiency can lead to significant cost savings and faster time-to-market, enhancing overall business performance. ↩

-

Understanding Battery Cycle Testing can help ensure product reliability and longevity, crucial for customer satisfaction. ↩

-

Exploring Motor Durability Analysis reveals how to enhance product performance and prevent costly failures. ↩