Got a brilliant idea for a groundbreaking toy, but the path from concept to customer seems overwhelmingly complex and expensive? Let's simplify it and turn your vision into a bestseller.

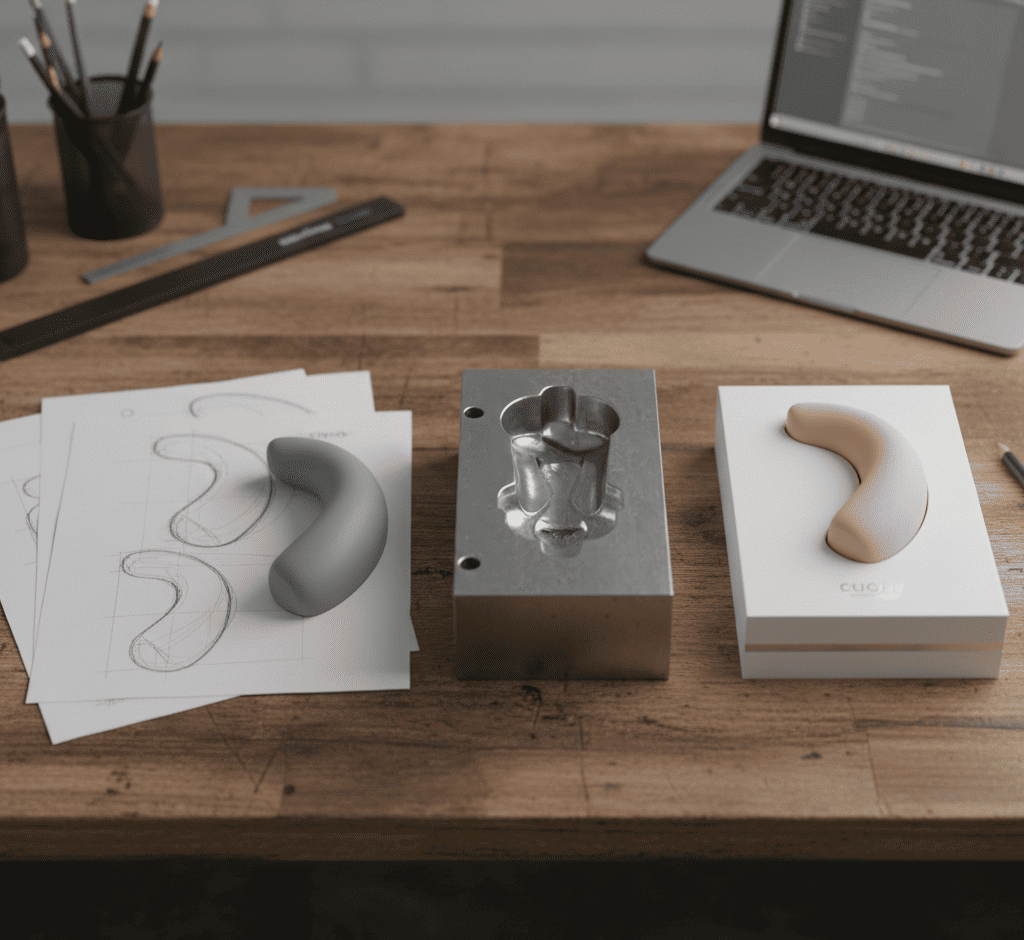

Creating successful custom sex toys involves a collaborative OEM process with an experienced manufacturer. This includes concept validation, 3D modeling, premium material selection, functional prototyping, and rigorous testing before mass production to ensure a market-ready product that sells.

Your entire role is built on sourcing innovative, high-quality products that fly off the shelves. You can't afford a dud. A failed product launch after months of development is a procurement head’s worst nightmare, wasting time, money, and damaging your brand's reputation for being on-trend. I've spent 15 years on the other side of this process, running VF Pleasure from our R&D center in Shenzhen and our sex toy factory in Anhui. I've seen countless ideas come through my door. The ones that succeed aren't just good ideas; they are good ideas backed by a true manufacturing partner, not just an order-taking factory. Let’s talk about how to make sure your next big idea becomes a profitable reality.

What's the Real Cost of Developing a Custom Sex Toy?

Worried about the massive upfront investment for development and molds? It's a valid fear. Hidden costs and unexpected delays can destroy your ROI before a single unit is even sold.

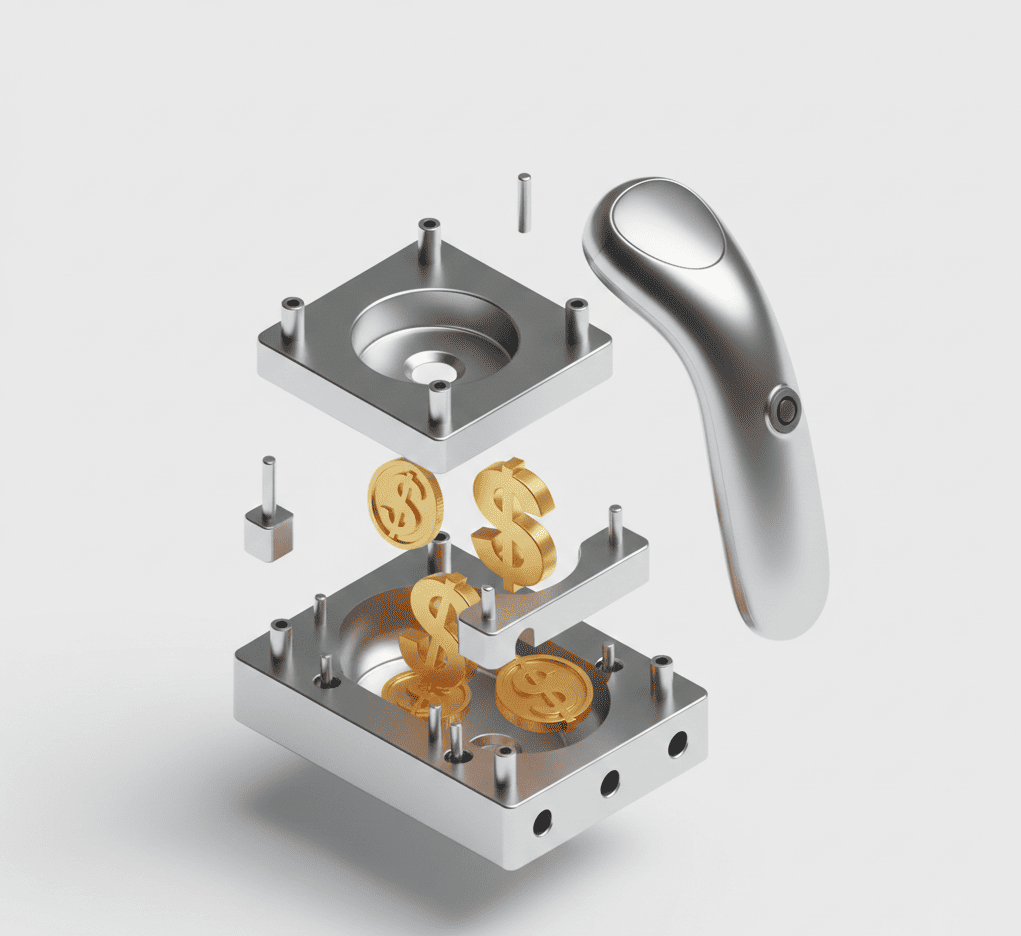

The primary investment for a custom sex toy is the mold (tooling), which can range from $10,000 to $25,000+. A transparent oem sex toys factory provides a detailed breakdown of all costs upfront and helps optimize your design to ensure cost-effectiveness.

One of your biggest pain points, Felle, is the high initial investment cost. Let's pull back the curtain on that. The bulk of the expense in any oem sex toys project is what we call NRE, or Non-Recurring Engineering and Tooling costs. This is a one-time investment to create the unique mold for your product. Anyone who tells you this is cheap is not being honest. However, a strategic partner can help you manage this cost. For example, during the design phase, my team might suggest a small modification to your concept that simplifies the mold's complexity, potentially saving you thousands of dollars without compromising the product's function. We believe in transparency. We provide a clear, itemized quote so you know exactly where your money is going. We want you to succeed because your success means a long-term partnership for us. It’s far better than a one-time, overpriced project. This is the difference you get when you work with a real dildo manufacturer versus a simple sourcing agent. You can learn more about our philosophy on our service page.

| Development Stage | Typical Cost Range (USD) | What You're Paying For |

|---|---|---|

| Design & Prototyping | $1,000 - $5,000 | Engineering time, 3D models, and functional samples for testing. |

| Tooling (Mold Creation) | $10,000 - $25,000+ | The high-precision steel mold used for mass production. This is your asset. |

| Certifications | $500 - $2,000 | Ensuring your product meets international standards like CE and RoHS. |

How Do You Ensure Your Custom Design Is Kept Confidential?

Your unique design is your competitive advantage. The fear of a manufacturer leaking that brilliant idea to a competitor is a major risk that keeps smart procurement heads up at night.

Protecting your idea is simple and non-negotiable: you need a Non-Disclosure Agreement (NDA). A professional custom sex toys factory will insist on signing an NDA before any sensitive details are shared, making confidentiality the foundation of your partnership.

Felle, your strategic mind knows that market uniqueness is invaluable. Your biggest fear should be your groundbreaking idea showing up under a competitor's brand. This is a real risk with unprofessional operations. At VF Pleasure, the very first step in any custom adult toys discussion is signing an NDA. It’s our policy. It signals that we respect your intellectual property and are serious about building a long-term, trusting relationship. Frankly, any adult toy manufacturer who is hesitant to sign one is a massive red flag. After 15 years in this business, my reputation is everything. We are not interested in a quick buck by stealing a design; we are interested in becoming your go-to partner for all your projects, from high-quality woman sex toys exporter needs to a new line of male adult toys. Your custom molds are your property, securely stored and used only for your orders. It’s a matter of trust and professional ethics, something you can learn more about on our about us page.

From Idea to Reality: What Does the OEM Process Look Like?

You have a vision, but the actual journey from a sketch on a napkin to a pallet of finished goods ready to ship feels like a black box. You need a clear, predictable roadmap.

The OEM (Original Equipment Manufacturer) process is a structured journey from idea to finished product. It moves through clear stages: Concept, Design, Prototyping, Tooling, Mass Production, and Logistics, ensuring your vision is realized accurately and efficiently.

Let's demystify the entire process. My job is to make this journey smooth and transparent for you, eliminating the anxieties about long lead times and product reliability. At our sex toys factory, we follow a proven six-step path for every oem adult products project.

- Concept & NDA: It starts with your vision. You bring us your idea, we sign the NDA, and we provide initial feedback based on our manufacturing experience.

- 3D Modeling & Design: Our engineers turn your concept into a detailed 3D digital blueprint. We work with you to refine every curve and feature until it's perfect.

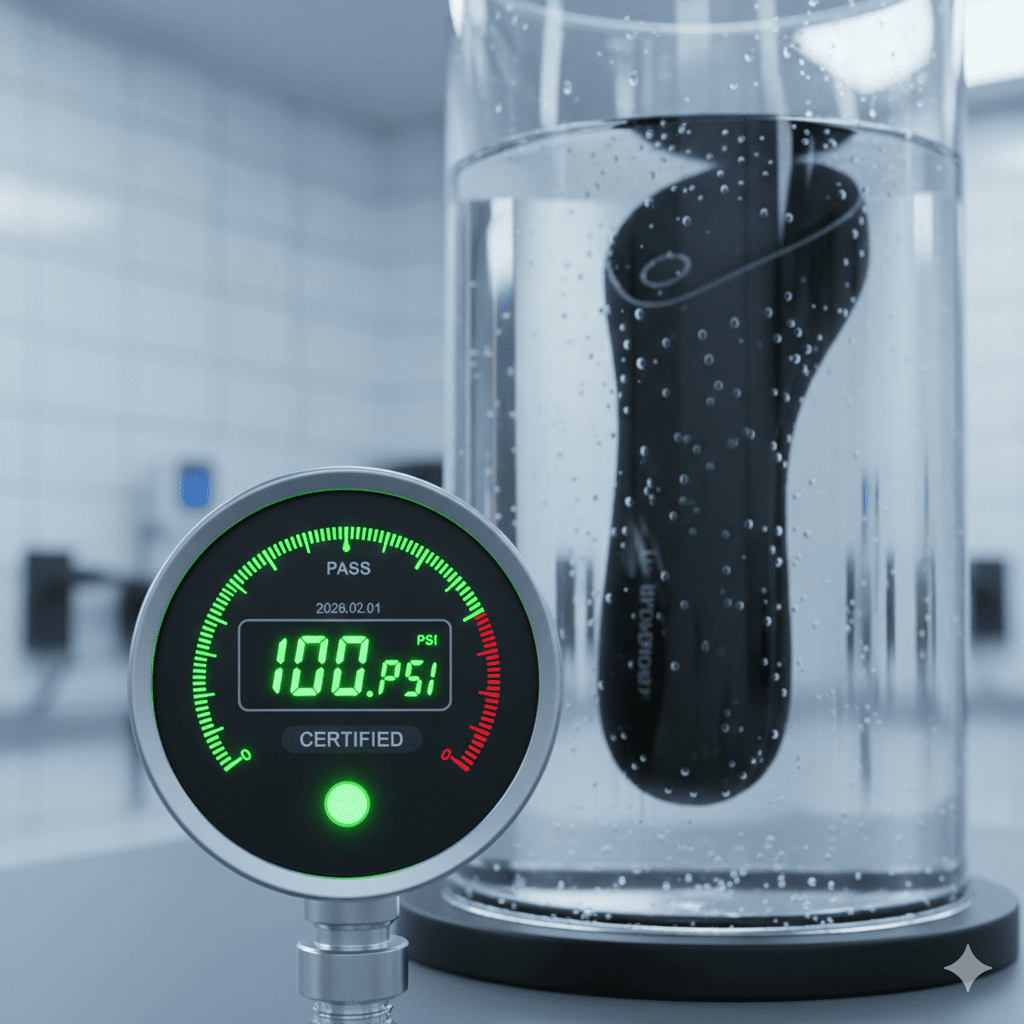

- Prototyping: This is where your idea becomes real. We create a physical, functional prototype using the exact materials, like body-safe silicone, for the final product. You get to test a real custom vibrator or whatever your product is.

- Tooling (Mold Creation): Once you approve the prototype, we create the high-precision steel mold. This is the most time-intensive part, but it's the key to flawless mass production.

- Mass Production & QA: With the mold complete, our production lines get to work. Our dedicated Quality Assurance team checks everything obsessively to ensure every unit is perfect.

- Packaging & Logistics: We work with you to create custom packaging and handle the complexities of shipping your final order of wholesale sex products to your warehouse.

This structured process, whether for a new thrusting sex toy or a line of private label sex toys, is our promise of reliability.

Conclusion

Creating custom sex toys isn't about finding the cheapest factory. It's about finding a dedicated OEM partner who will protect your ideas, guide you through a transparent process, and deliver the high-quality, innovative products your brand deserves.