Private label brands are missing out on a goldmine. The male wellness market is exploding, yet most retailers still focus only on traditional products.

OEM penis massager manufacturing requires specialized materials, custom molding techniques, and unique motor systems. Success depends on choosing experienced manufacturers who understand sleeve materials, heating functions, and modular designs that enhance user experience and product longevity.

After 15 years in this industry, I've watched countless brands discover the untapped potential in male-focused adult wellness products. The manufacturing complexities might seem daunting, but the rewards are substantial for those willing to invest in quality partnerships.

- 1 What Makes Penis Massager OEM Manufacturing Different from Traditional Adult Toys?

- 2 How Do You Choose the Right OEM Manufacturer for Penis Massager Production?

- 3 What Design Features Drive Success in Private Label Penis Massagers?

- 4 How Should Private Label Brands Position Penis Massagers in the Market?

- 5 What Are the Profit Margins and Investment Requirements?

- 6 Conclusion

What Makes Penis Massager OEM Manufacturing Different from Traditional Adult Toys?

The technical challenges caught me off guard when I first entered this segment. Standard vibrator manufacturing knowledge doesn't translate directly to penis massagers.

Penis massager OEM requires specialized TPE or silicone sleeve materials, precise durometer testing, custom internal texturing, and motor systems designed for different stimulation patterns than traditional vibrators. Manufacturing costs are 30-40% higher than standard adult toys due to complex sleeve molding and specialized components.

The sleeve materials demand the most attention in my adult toy factory. We work with specialized TPE1 compounds that require precise durometer ratings between 15-25 Shore A. Too soft, and the product lacks structural integrity. Too firm, and user comfort suffers dramatically.

Internal texturing represents another manufacturing challenge. Unlike external toys where texture is applied to outer surfaces, penis massagers require internal chamber designs with varying pressure zones. Our custom molding process creates multiple chambers within single sleeves, allowing different stimulation experiences.

Motor systems need complete redesigning for this product category. Traditional bullet motors work poorly in penis massager applications. We develop linear actuator systems and air pressure mechanisms that create suction and thrusting motions. These specialized motors increase manufacturing costs by 25-30% but deliver superior user experiences.

| Component | Traditional Toys | Penis Massagers | Cost Impact |

|---|---|---|---|

| Motor System | Bullet/Rotating | Linear/Suction | +25-30% |

| Materials | Standard Silicone | Specialized TPE | +15-20% |

| Molding Process | Simple Injection | Multi-Chamber | +20-25% |

| Testing Requirements | Basic Function | Durometer/Pressure | +10-15% |

How Do You Choose the Right OEM Manufacturer for Penis Massager Production?

Finding the right adult toy manufacturer requires understanding specialized capabilities. Most factories focus on female-oriented products and lack male toy expertise.

Choose OEM manufacturers with dedicated male toy production lines, specialized sleeve molding equipment, experience in heating element integration, and proven track records in modular design systems. Verify their quality testing capabilities for durometer measurement and pressure testing.

VF Pleasure's production lines specifically handle male wellness products2 with dedicated equipment for sleeve manufacturing. We maintain separate molding systems for TPE and silicone components, preventing cross-contamination between materials.

Heating function integration separates experienced manufacturers from novices. Adding heating elements increases manufacturing costs by 15-20%, but market research shows perceived value increases by 40-50%. The electrical safety testing alone requires specialized equipment that many factories lack.

Modular design capability proves crucial for long-term success. Our most successful private label clients specify user-replaceable sleeves. This design approach requires precision manufacturing where sleeve tolerances must match device housings exactly. Poor fit results in air leaks and reduced suction performance.

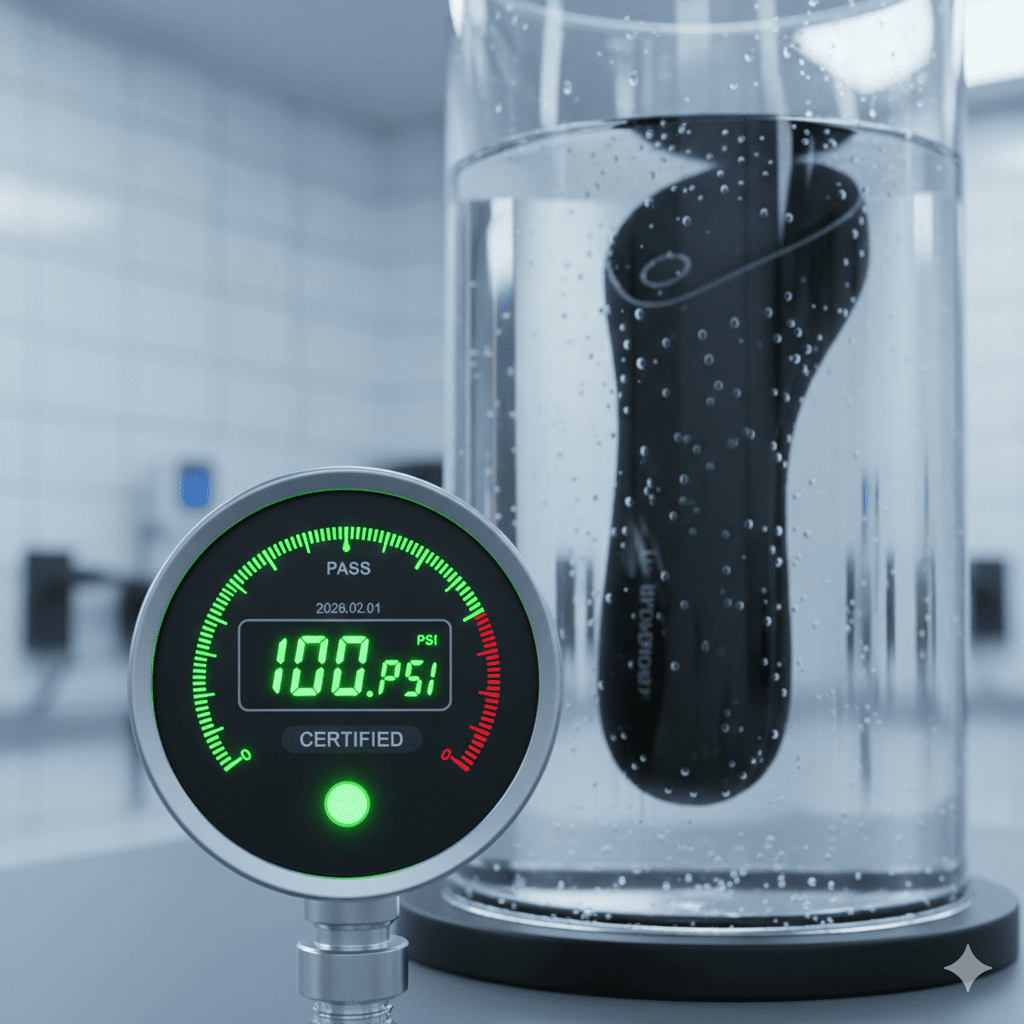

Quality testing goes beyond basic functionality. We perform durometer testing on every batch of sleeve materials, pressure testing for suction mechanisms, and thermal testing for heating elements. Many factories skip these specialized tests, leading to inconsistent product quality.

Minimum order quantities vary significantly between manufacturers. Established adult toy suppliers like us offer flexible MOQs starting at 500 units for initial orders, scaling up for production runs. This flexibility allows brands to test markets before committing to large inventories.

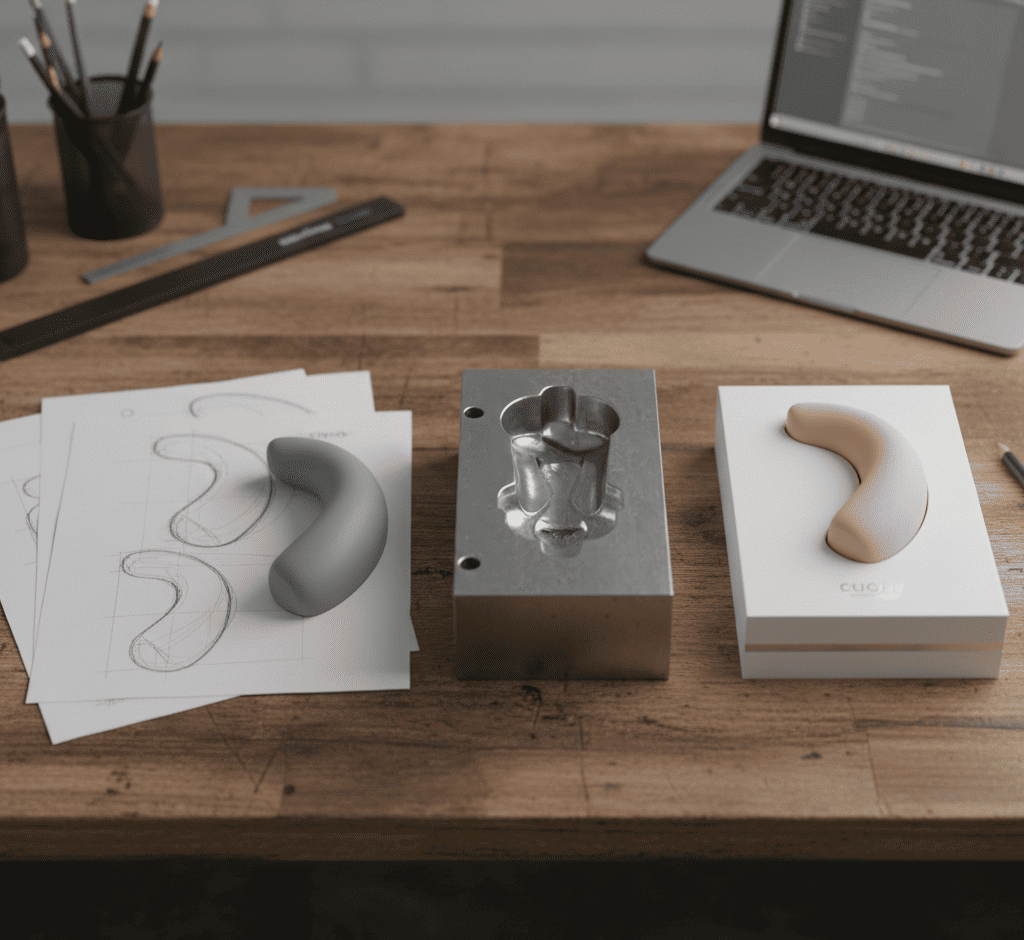

What Design Features Drive Success in Private Label Penis Massagers?

Market success depends heavily on specific design elements that enhance user experience and product longevity. I've tested countless configurations to identify winning features.

Successful penis massager designs prioritize discretion, easy maintenance, modular components, and heating functions. Focus on removable dishwasher-safe parts, compact charging systems, and sleeve replaceability for maximum customer satisfaction and repeat purchases.

Discretion ranks as the top priority for male wellness products. Our [custom adult toys](https://www.vibratorfactory.com/blog-private-label-sex-toys-5-benefit.html)3 feature minimalist designs that don't immediately reveal their purpose. Compact charging cases double as storage solutions, addressing privacy concerns that dominate this market segment.

Maintenance simplicity directly impacts customer satisfaction. Our best-performing models feature completely removable sleeves that separate from electronic components. Users can clean sleeves in dishwashers or with standard soap and water without damaging sensitive electronics.

Modular sleeve systems4 create additional revenue opportunities. Replacement sleeves typically sell for 30-40% of original product prices with 70-80% profit margins. Brands can offer different textures, sizes, or materials as upgrade options, building customer loyalty through variety.

Heating elements transform user experience when implemented correctly. We integrate heating coils throughout device housings, not just in sleeves. This approach ensures even temperature distribution and prevents hot spots that cause discomfort. Temperature control systems maintain 98-102°F ranges automatically.

Suction mechanisms require careful engineering. Air pressure systems create suction through controlled airflow rather than vacuum pumps. This approach reduces noise levels significantly while providing consistent pressure across different user sizes and preferences.

| Design Feature | User Benefit | Manufacturing Cost | Retail Value Impact |

|---|---|---|---|

| Heating System | Enhanced Comfort | +15-20% | +40-50% |

| Modular Sleeves | Easy Cleaning | +10-15% | +25-30% |

| Compact Design | Discretion | +5-10% | +20-25% |

| Suction Control | Customization | +20-25% | +35-40% |

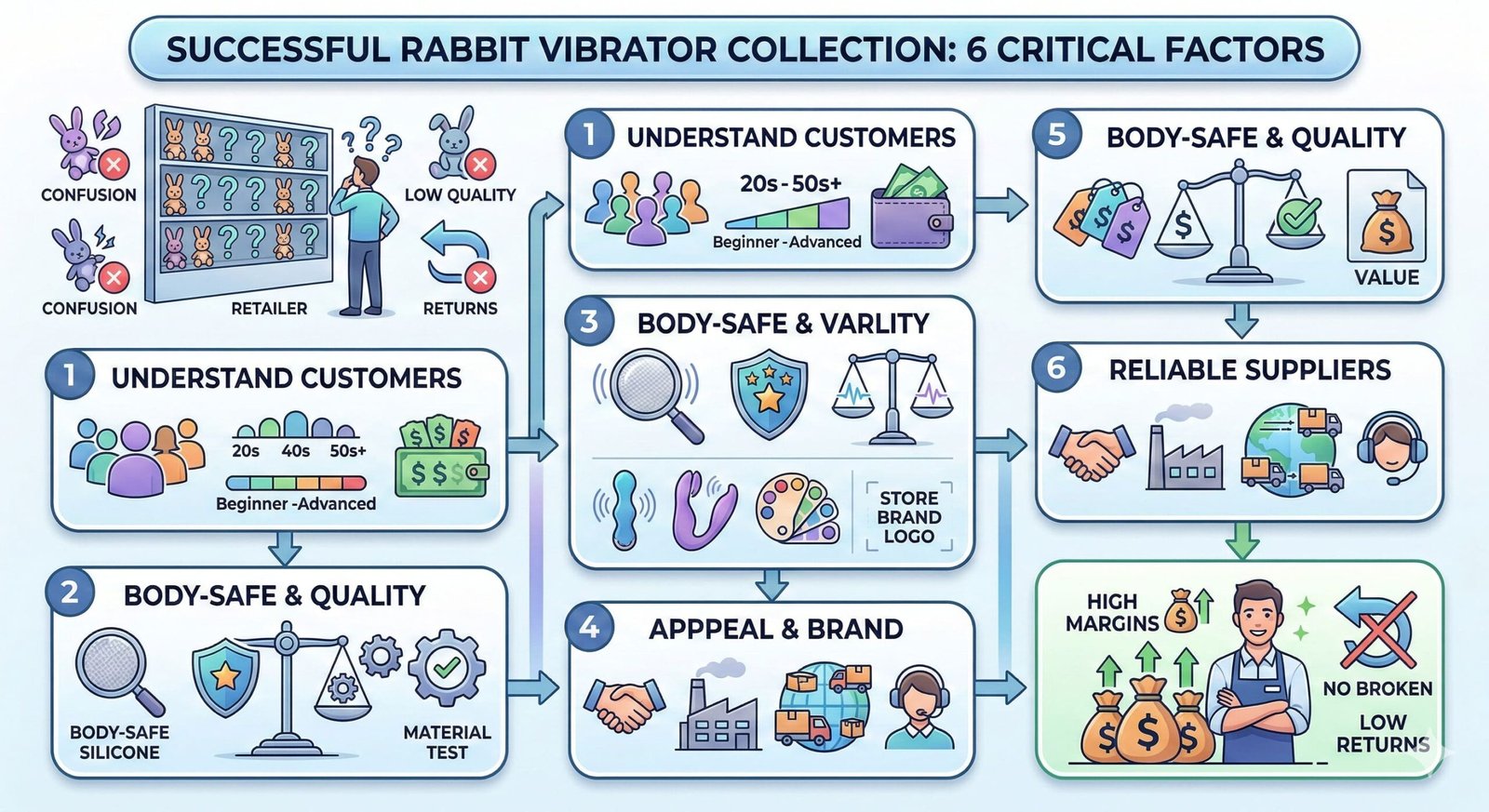

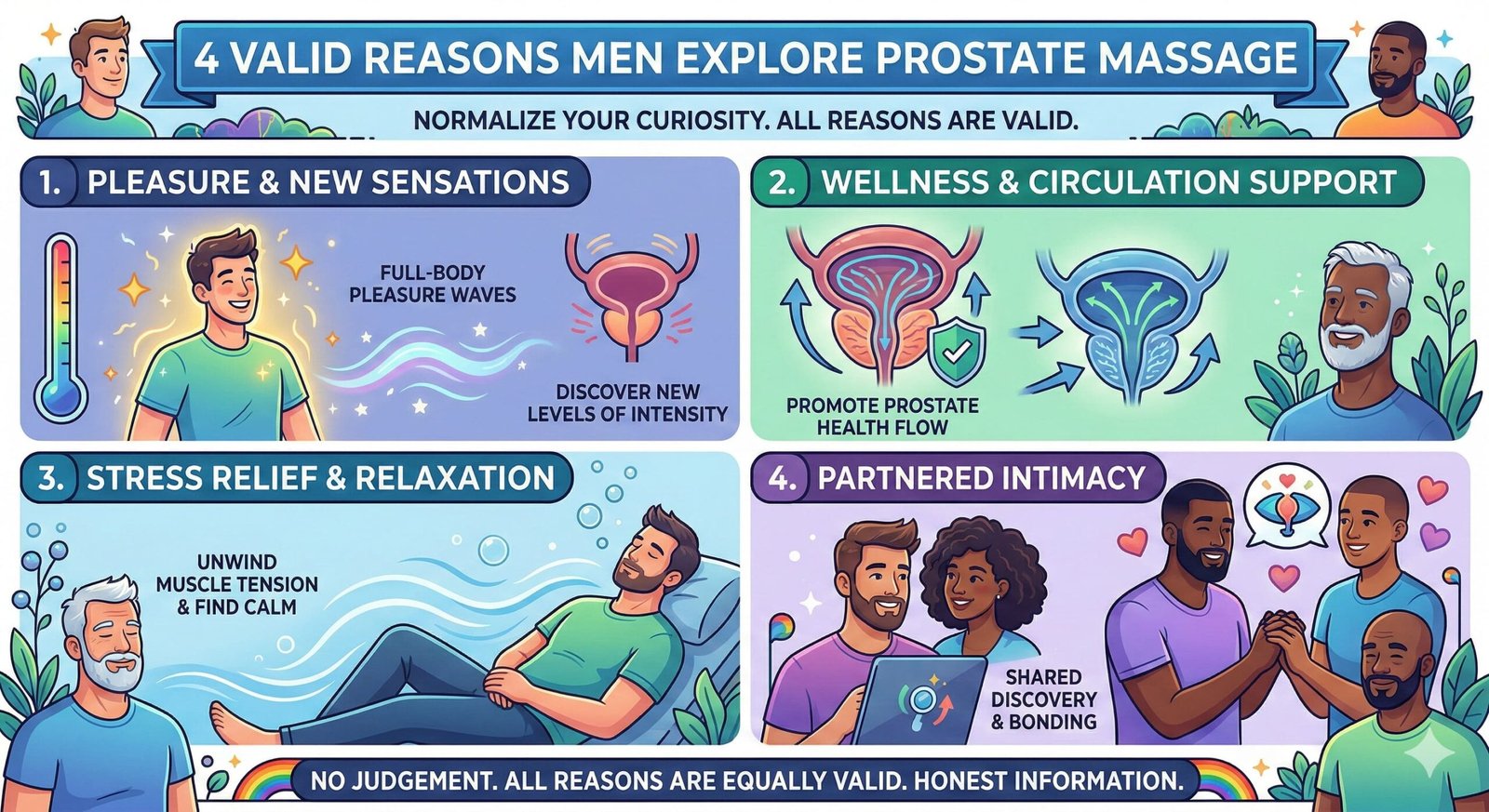

How Should Private Label Brands Position Penis Massagers in the Market?

Marketing positioning makes or breaks success in male wellness products. The approach differs dramatically from traditional adult toy marketing strategies.

Frame penis massagers as wellness and stress-relief products rather than purely recreational items. Focus on health benefits, discretion, and quality of life improvements. Avoid explicit imagery and emphasize personal care, relaxation, and wellness lifestyle positioning.

Wellness positioning works better than recreational marketing. Our private label partners achieve higher conversion rates when emphasizing stress relief5, improved sleep quality, and personal wellness benefits. Medical-style packaging and terminology increase perceived legitimacy.

Customer education requires significant investment but pays long-term dividends. I work with brands to develop comprehensive user guides, video tutorials, and FAQ sections. Male consumers typically research extensively before purchasing, making educational content crucial for conversion.

Discretion extends beyond product design to packaging and shipping. Plain packaging without branding or product descriptions protects customer privacy. Many successful brands offer discreet billing descriptors and unmarked shipping boxes as standard practices.

Pricing strategies need careful consideration. Premium pricing works when supported by quality manufacturing and education. Our OEM adult products typically retail between $89-249, with higher prices justified through heating functions, premium materials, and modular designs.

Distribution channels matter enormously. Online direct-to-consumer sales work better than traditional adult retail for male products. Men prefer private purchasing experiences without face-to-face interactions. E-commerce platforms allow detailed product descriptions and customer reviews that build confidence.

What Are the Profit Margins and Investment Requirements?

Understanding financial requirements helps brands make informed manufacturing decisions. The numbers look attractive but require patient market development.

Penis massager OEM typically offers 60-70% retail margins with initial investments of $15,000-50,000 for first production runs. Manufacturing costs range from $12-35 per unit depending on features, with retail prices from $89-249. ROI timelines average 12-18 months.

Manufacturing costs6 vary significantly based on feature complexity. Basic models with standard sleeves and simple motors cost $12-18 per unit. Premium versions with heating, multiple sleeves, and advanced suction systems reach $25-35 per unit at our sex toys manufacturer facility.

Initial investment requirements include tooling costs, minimum order quantities, and marketing budgets. Tooling for custom designs ranges from $2,000-8,000 per product. MOQs typically start at 500-1,000 units for initial orders, scaling to 2,000-5,000 for production runs.

Market development requires patience and consistent investment. Unlike established product categories, male wellness items need customer education and market conditioning. Successful brands budget 20-30% of gross revenue for marketing during the first two years.

Replacement sleeve revenue provides ongoing profit opportunities. Sleeves cost $3-6 to manufacture but retail for $25-45. Customers typically purchase replacement sleeves every 3-6 months, creating recurring revenue streams that improve overall profitability.

International market expansion offers significant upside potential. European and Australian markets show higher male wellness product acceptance rates than North American markets. Export opportunities through experienced adult toy manufacturers can double or triple addressable markets.

Conclusion

Penis massager OEM manufacturing offers substantial opportunities for private label brands willing to invest in specialized partnerships, quality design, and patient market development.

-

Explore how specialized TPE enhances the quality and user experience of adult toys, ensuring safety and comfort. ↩

-

Explore this link to understand the growing importance and benefits of male wellness products in today's market. ↩

-

Explore this link to understand how custom adult toys enhance user experience and satisfaction. ↩

-

Discover how modular sleeve systems can boost product versatility and customer loyalty in the adult toy market. ↩

-

Explore this link to understand how stress relief products can enhance well-being and improve quality of life. ↩

-

Understanding manufacturing costs is crucial for budgeting and pricing strategies in any business. ↩