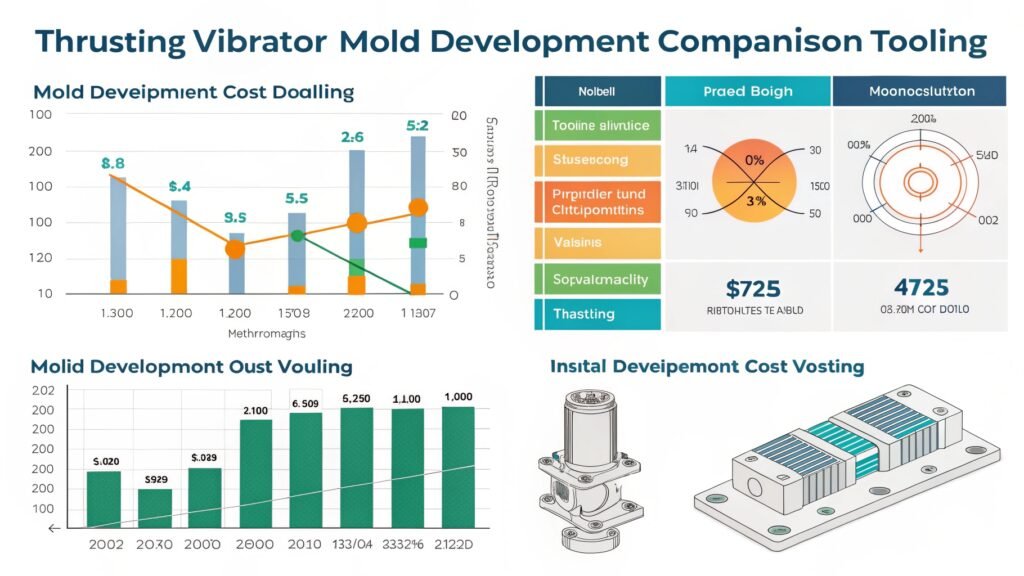

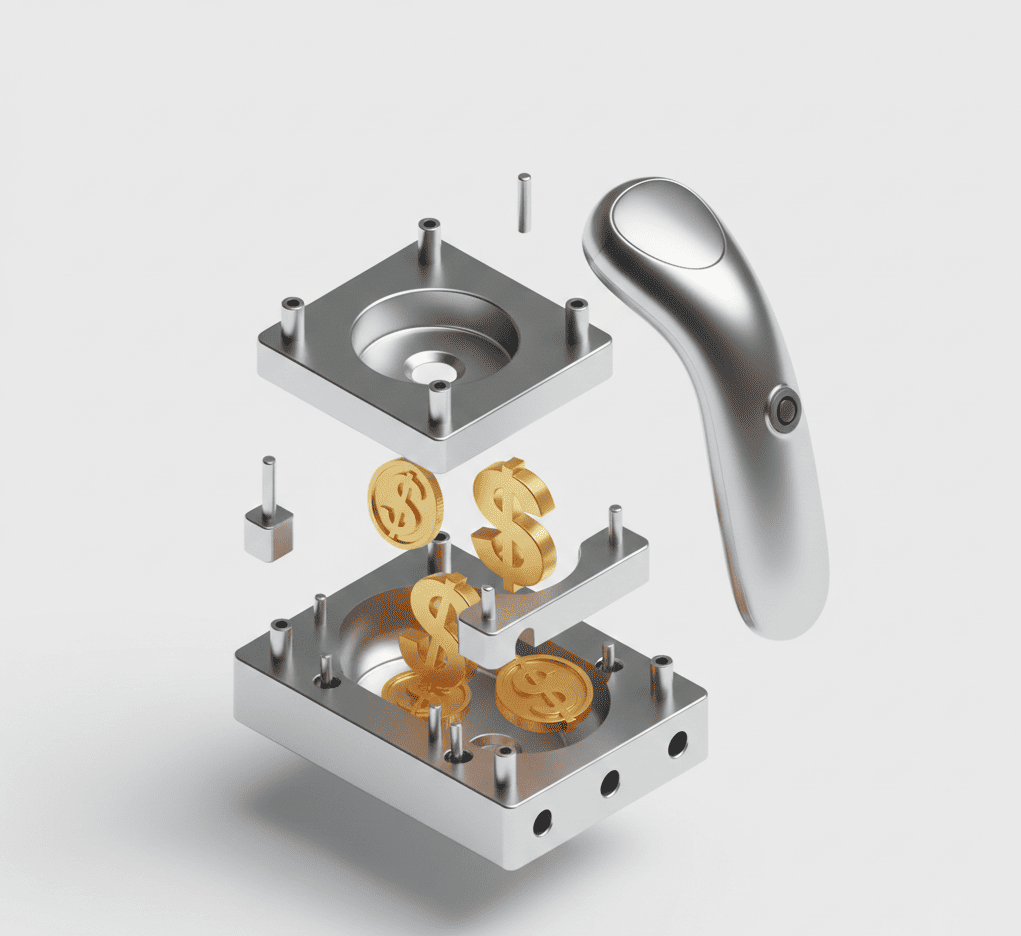

Thrusting vibrator OEM costs catch manufacturers off-guard with hidden expenses that destroy profit margins.

Cost Structure Overview: Motor assemblies represent 35-40% of manufacturing costs, molds cost $8,000-15,000, packaging accounts for 8-12%, and logistics run $2.80-4.20 per unit. Total investment requires 25-35% premium over standard vibrators.

Managing our DongGuang production lines taught me that thrusting products have unique cost drivers that differentiate them significantly from standard vibrators.

What Percentage of OEM Costs Do Thrusting Motors Represent?

Motor assemblies create the highest cost component in thrusting vibrator manufacturing programs.

Motor Cost Impact: Thrusting motors represent 35-40% of total manufacturing costs—significantly higher than conventional toys. Standard motors cost $12-18 per unit, while custom specifications reach $25-35 per unit.

Motor Assembly Cost Analysis

From managing our production lines, I've learned that motor assemblies typically represent 35-40% of total manufacturing costs for thrusting sex toys—significantly higher than conventional products.

Motor costs vary dramatically based on customization requirements. Standard thrusting motors cost $12-18 per unit for basic stroke patterns and torque specifications. Custom torque requirements or specialized stroke patterns can reach $25-35 per unit.

At VF Pleasure, we maintain relationships with three motor suppliers to ensure competitive pricing without compromising reliability standards for our adult toy manufacturer operations.

Motor Cost Breakdown:

- Standard thrusting motors: $12-18 per unit

- Custom torque specifications: $20-28 per unit

- Specialized stroke patterns: $25-35 per unit

- Premium noise reduction motors: $30-40 per unit

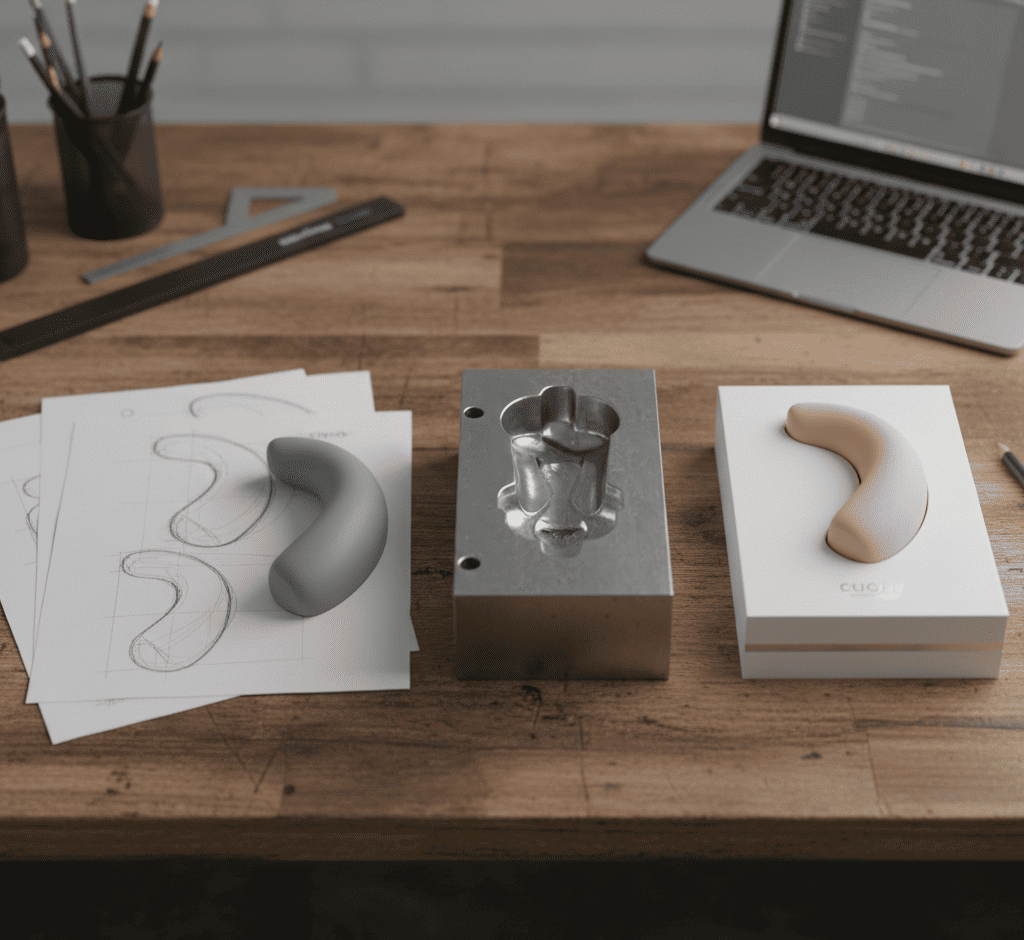

How Much Do Thrusting Vibrator Molds Cost Compared to Standard Designs?

Mold development for thrusting products requires 20-30% higher investment than conventional vibrator tooling.

Mold Investment Range: Thrusting vibrator molds cost $8,000-15,000 depending on complexity. Dual-cavity designs require additional investment for proper motor housing integration and precision tolerances.

Mold Development Investment Requirements

Mold development for thrusting products runs $8,000-15,000 depending on complexity, with dual-cavity designs requiring additional investment for proper motor housing integration.

The precision tolerances needed for seamless motor operation add 20-30% to standard molding costs. I've seen clients underestimate this factor, then face performance issues when trying to economize on mold specifications.

- Single-cavity basic design: $8,000-10,000

- Dual-cavity production molds: $12,000-15,000

- Complex motor housing integration: +$2,000-3,000

- Precision tolerance requirements: +20-30% baseline costs

- Multi-texture surface finishing: +$1,500-2,500

Our custom sex toys require precise mold specifications because motor housing tolerances directly impact thrusting performance and product longevity.

What Are the Packaging and Logistics Costs for Thrusting Vibrators?

Packaging and logistics represent significant cost components requiring careful budget allocation and supplier negotiation.

Cost Percentages: Packaging represents 8-12% of total costs, while logistics from DongGuang run $2.80-4.20 per unit for European destinations, depending on packaging density and volume commitments.

Packaging and Shipping Investment Analysis

Packaging represents 8-12% of total costs for our [adult novelty wholesale](https://flxpoint.com/blog/adult-products-dropshipping-guide)2 operations, with premium presentation materials adding significant value perception for retail positioning.

Logistics from DongGuang typically run $2.80-4.20 per unit for European destinations, depending on packaging density3 and shipping volume commitments. Larger orders achieve better per-unit shipping rates.

Packaging Cost Structure:

- Basic retail packaging: 8-10% of total costs

- Premium presentation boxes: 10-12% of total costs

- Custom branding materials: +$1.50-2.50 per unit

- Protective shipping materials: $0.80-1.20 per unit

Logistics Variables:

- European shipping: $2.80-4.20 per unit

- North American destinations: $3.20-4.80 per unit

- Volume commitments reduce rates by 15-25%

How Do Material Costs Impact Thrusting Vibrator Pricing?

Material expenses significantly influence final product pricing and require strategic supplier relationships for cost control.

Material Cost Impact: Platinum silicone accounts for 15-20% of production expenses. Quality suppliers have increased prices 18% over two years, making material selection crucial for maintaining margins.

Material Cost Management Strategy

Material costs—primarily platinum silicone—account for 15-20% of production expenses for quality sex toy factory operations. Quality silicone suppliers have increased prices 18% over the past two years.

Making material selection crucial for maintaining healthy profit margins on private label sex toys programs.

Material Cost Breakdown:

- Food-grade platinum silicone: 15-18% of total costs

- Motor housing materials: 3-5% of total costs

- Internal lubricants and assemblies: 2-3% of total costs

- Quality control testing: 1-2% of total costs

The key insight: successful thrusting vibrator programs require 25-35% higher initial investment than standard products but deliver superior customer retention rates that justify premium positioning strategies.

Conclusion

Understanding these cost components ensures profitable thrusting vibrator OEM partnerships and realistic pricing strategies.

-

Understanding mold cost factors is crucial for budgeting and ensuring product quality in manufacturing. ↩

-

Explore this link to understand effective strategies for packaging and shipping in the adult novelty industry. ↩

-

Learn about the impact of packaging density on shipping costs to optimize your logistics and save money. ↩