Curious about adult toy creation? It's complex. Unseen efforts bring pleasure and innovation to life for users.

Adult toy manufacturers craft pleasure and innovation through meticulous design, careful material selection, precise manufacturing processes, rigorous quality control, and a constant drive for new technologies. This ensures safe, satisfying, and advanced products for users.

Many people only see the final product on a shelf or website. But as someone who's spent 15 years in this industry, I, Sally from VF Pleasure, can tell you there's a whole world of activity that happens before that. It's a blend of art, science, and engineering. For procurement heads like Felle, understanding this "behind the scenes" look is crucial for choosing a reliable partner who values quality and innovation as much as you do. Let’s pull back the curtain.

What is the Role of Design and Prototyping in Adult Toy Creation?

Bad design sinks great ideas. Prototyping feels slow. Get it wrong, and you waste time and money.

Design and prototyping are foundational in adult toy creation. This stage translates concepts into tangible forms, allowing for ergonomic refinement, functional testing, and aesthetic finalization before mass production, ensuring market viability.

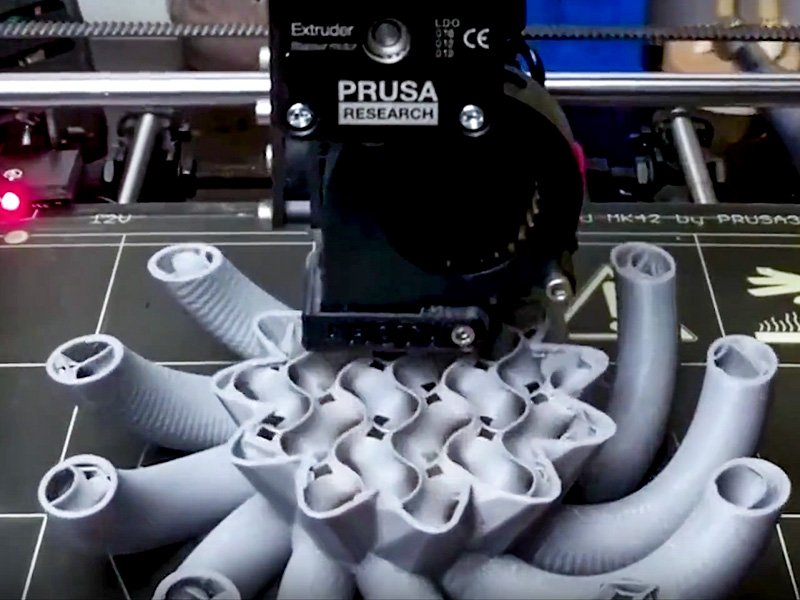

At VF Pleasure, the journey often begins with an idea – either from our client or our in-house R&D team in Shenzhen. The design phase isn't just about making something look good; it's about how it feels, how it works, and if it can be manufactured efficiently. We use 3D modeling software to create initial designs for vibrators or female sex toys. This allows for quick iterations. Then comes prototyping. This involves creating a physical model, often using 3D printing for speed. This prototype is crucial. Felle, you'd appreciate this – it's where you can physically assess the ergonomics, the button placement, the overall feel. We test it. We get feedback. We refine it. This iterative process, part of our custom product development [^3], might seem time-consuming, but it prevents costly mistakes down the line. Rushing this, as some do, can lead to project failure [^5]. A solid prototype ensures the final product truly delivers on its promise of pleasure and innovation, meeting the high standards you expect.

How Are Materials Selected for Safety and Sensation in Adult Toys?

Worried about product safety? The wrong materials can harm users and your brand's reputation. Material choice is critical.

Materials for adult toys are selected based on body safety, tactile sensation, durability, and manufacturing compatibility. Prioritizing medical-grade or food-grade silicone and non-toxic plastics like ABS is key for user well-being and product quality.

Material selection is a cornerstone of responsible adult toy manufacturing, something we take very seriously at VF Pleasure [^4]. For products like male adult toys or couples toys that come into intimate contact with the body, safety is paramount. We primarily use food-grade platinum silicone and medical-grade silicone. These materials are non-porous, hypoallergenic, and easy to clean, making them ideal for intimate use. We also use high-quality ABS plastic for internal structures or certain product types, ensuring it’s phthalate-free and body-safe [^2]. The "sensation" part is also vital. Silicone offers a soft, skin-like feel, while different hardness levels (durometers) can be chosen for varied firmness. The texture and finish of the material are also carefully considered during the design phase to enhance the user experience. We ensure our materials comply with international standards like CE and RoHS [^2], providing you, Felle, with the assurance of safety and quality you need for your retail chain and for ultimate customer satisfaction.

What Does the Manufacturing and Assembly Process Look Like in an Adult Toy Factory?

Wondering how toys are actually made? It's not magic. It's a precise, multi-step process requiring skill and technology.

The adult toy manufacturing process involves mold creation, material injection or pouring, component assembly (motors, electronics), finishing, and packaging. Each step is carefully managed on production lines to ensure consistency and quality.

Once designs are finalized and materials chosen, we move to mold creation. This is a significant step, especially for our OEM/ODM solutions. High-precision molds are made from steel, which are then used for injection molding (for ABS parts) or silicone casting/molding. At our factory in Dongguan, with its five production lines , this is where the physical product starts to take shape. For silicone parts, the liquid silicone is injected or poured into the molds and then cured. For electronic components like motors in thrusting sex toys or control boards, these are often sourced from specialized suppliers and then integrated during the assembly phase. Our skilled workers assemble these components meticulously. This might involve soldering, connecting wires, and fitting parts together. The process is designed for efficiency but also for precision. It’s a blend of automated processes and manual dexterity to ensure each product functions as intended. We've streamlined this; our OEM service portal, for instance, can cut development time [^5], getting your innovative products to market faster.

How is Quality Control and Testing Ensured in Adult Toy Production?

Afraid of faulty products reaching customers? Strict quality control isn't just a promise; it's a systematic process.

Quality control in adult toy production involves multiple checkpoints: incoming material inspection, in-process checks during assembly, and final product testing for functionality, safety, and aesthetics. This ensures every item meets specifications.

Quality control (QC) is not an afterthought; it's integrated throughout our entire manufacturing process at VF Pleasure. Felle, as someone who prioritizes reliability, you'll understand the importance of this. It begins with inspecting raw materials – is the silicone up to spec? Are the electronic components working? Then, during assembly on our production lines, we have in-process checks. For example, after a motor is installed in a vibrator, it's tested. Before a product is sealed, all internal connections are verified. The final stage is perhaps the most rigorous. Every single finished product, whether it's for our private label sex toys clients or our own lines, undergoes functional testing. Does it vibrate correctly? Do all buttons work? Is the charging port functional? We also check for aesthetic flaws. This commitment to certified quality assurance and meeting international standards is crucial for building trust and ensuring customer satisfaction. It's about delivering products that work perfectly, every time, maintaining your brand's reputation.

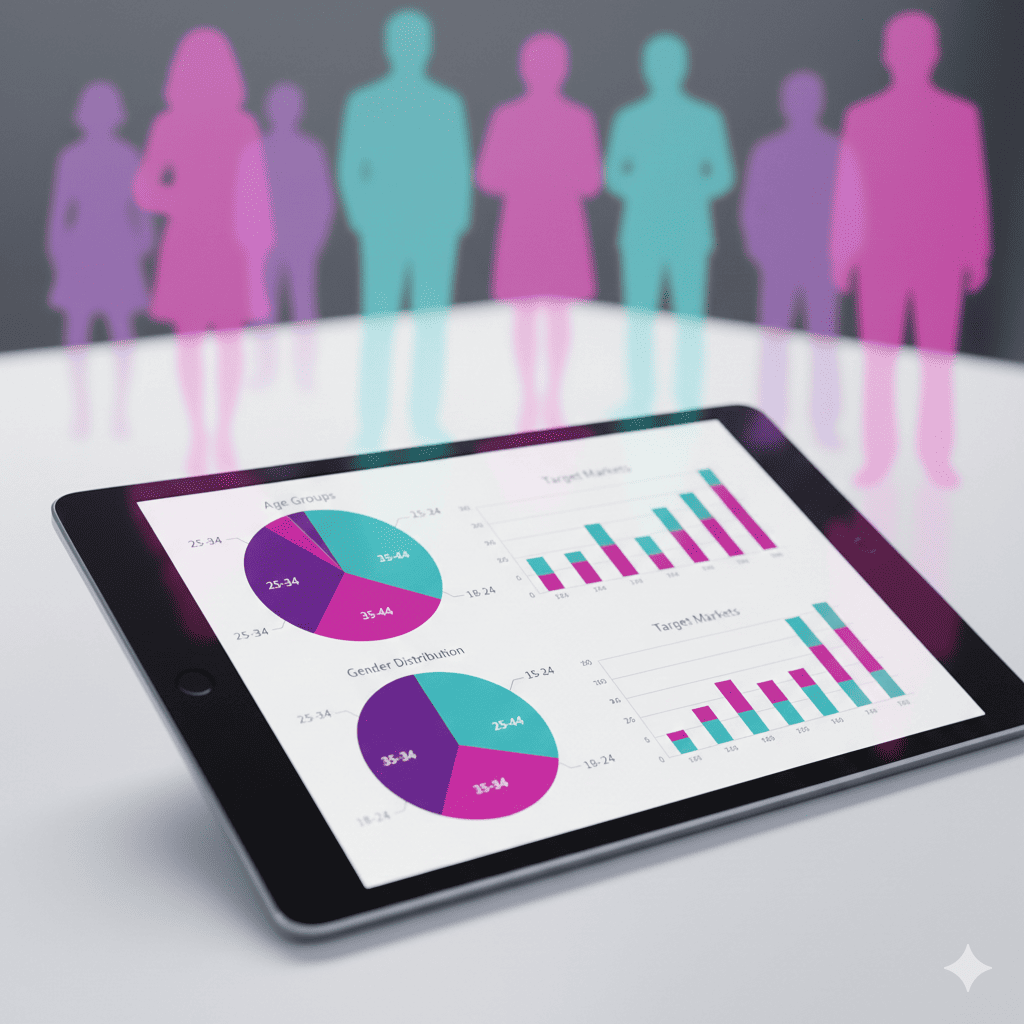

How Do Manufacturers Drive Innovation in Pleasure Products?

Is the adult toy market static? Far from it. Constant innovation is key to meeting evolving desires and technology.

Manufacturers drive innovation in pleasure products through R&D in new materials, motor technologies, ergonomic designs, app connectivity, and user experience features. This commitment to advancement creates more satisfying and diverse products.

Innovation is the lifeblood of the adult toy industry, and it's a core focus for us at VF Pleasure. It’s not just about new shapes; it’s about enhancing the user experience. Our R&D center in Shenzhen [^1] is always exploring. This includes advancements in motor technology for quieter, more powerful, or more varied vibration patterns in our vibrators. We look into new materials that might offer different sensations or are more eco-friendly. App-controlled toys are a big area of innovation, allowing for remote play and customized experiences, especially relevant for couples toys. We also focus on ergonomic designs that are more intuitive and comfortable. For example, developing a new type of stimulator for female sex toys might involve extensive user feedback and testing. This drive for innovation is crucial for brands like yours, Felle, that want to offer a diverse, high-quality product range aligned with market trends. It's about anticipating what customers will want next and having the capability to deliver it. Our About Us page highlights our commitment to this ongoing evolution.

Conclusion

Crafting pleasure and innovation involves meticulous design, safe materials, precise manufacturing, rigorous testing, and a constant drive to improve products.