Starting your adult products business feels exciting, but finding the right wholesale partner without breaking the bank can feel overwhelming. You need quality products, reasonable prices, and flexibility—especially when you're just testing the waters or working with limited capital.

If you're looking for adult novelty wholesale options with low MOQs, your best approach depends on your business goals. Local distributors and trading companies typically offer the lowest minimum orders (often under 50 mixed units), making them ideal for immediate inventory needs. However, working directly with experienced adult toy manufacturers like VF Pleasure provides better long-term value through white label solutions that balance factory-direct pricing with manageable starting volumes.

The key isn't just finding any supplier—it's finding the right partner who understands your growth trajectory. Let me walk you through the real options available and help you make a decision that actually serves your business model.

What Are the Best Sources for Low MOQ Adult Toy Purchases?

Finding wholesale sex toys with flexible minimums requires understanding the supplier landscape. Your choices affect not just your initial investment, but your profit margins and brand potential for years to come.

Three main channels exist for low MOQ adult novelty purchases: domestic wholesalers (typically 10-50 units mixed), trading companies (50-200 units), and direct manufacturers with white label programs (100-500 units with your branding). Each serves different business needs and growth stages.

Understanding Your Real Sourcing Options

After 15 years in this industry, I've watched countless entrepreneurs make sourcing decisions. The pattern is clear—your choice must align with your actual business model, not just your current budget constraints.

Domestic Adult Toy Wholesalers

Local wholesale adult toys distributors represent the path of least resistance. These adult toy wholesalers maintain inventory and ship quickly, usually within your country. You can order as few as 10-20 mixed units.

The trade-off? Your per-unit costs run 40-60% higher than factory-direct pricing. For someone testing market response with $500-1000, this makes perfect sense. You minimize risk while learning customer preferences.

I've seen retailers successfully use this model for 12-18 months before transitioning to direct manufacturing relationships. One client in California started with a local adult wholesale direct supplier, identified her three best-selling categories, then came to us for private label versions at half her previous cost.

Trading Companies and Middlemen

The middle ground involves trading companies specializing in bulk adult toys. They typically require 50-200 unit minimums across fewer SKUs. Their pricing falls between domestic wholesalers and manufacturers—usually 20-35% above factory cost.

These companies serve a purpose. They handle import logistics, quality inspection, and often provide mixed container consolidation. If you need 100 vibrators, 50 dildos, and 50 male toys but want someone else managing the supply chain complexity, trading companies deliver value.

The limitation? You're still paying for their operational overhead and profit margin. As your volumes grow past 500 units per order, this margin becomes increasingly difficult to justify.

Direct Manufacturer Partnerships

This is where my perspective becomes obviously biased—but for good reasons grounded in mathematics, not just self-interest. Working with an adult toy manufacturer like VF Pleasure offers the best long-term value equation.

Our typical white label minimum sits around 300-500 units for existing mold designs. Yes, that's higher than a local wholesaler's 20-unit minimum. But let's examine the actual numbers.

At our DongGuan factory, we maintain over 200 existing molds across vibrators, female sex toys, male adult toys, and couples toys. These aren't generic products—they're designs we've refined through years of market feedback and R&D investment.

When you choose one of these existing designs for your private label, you get:

- Factory-direct pricing (typically 60-70% below retail)

- Your custom branding and packaging

- Quality control from source

- Scalable production capacity

- Technical support and product knowledge

I recently worked with David, a procurement head for a growing retail chain. He initially balked at our 500-unit minimum for a custom vibrator design. I suggested our white label approach instead—choosing from our existing thrusting sex toys collection with his branding.

His per-unit cost dropped 45% compared to his previous trading company supplier. More importantly, he controlled his brand identity and product quality from day one. Six months later, he returned for a fully custom OEM project with a 2,000-unit order.

How Do MOQs Actually Impact Your Business Model?

Understanding minimum order quantities means more than just counting units. It's about cash flow, inventory turnover, and strategic positioning. I've made this mistake myself early in my career—focusing on the wrong metrics.

MOQs directly affect your working capital requirements, storage costs, and pricing flexibility. A 50-unit order at $15/unit ($750 total) with 100% markup yields $1,500 revenue but limits your margin for market testing. A 500-unit order at $6/unit ($3,000 total) with the same markup generates $15,000 revenue and provides room for promotional pricing without eroding profitability.

The Real Cost of "Low" Minimums

This might sound counterintuitive, but extremely low MOQs often cost you more money in the long run. Let me break down why.

Hidden Costs in Small Order Quantities

When you buy 20 units from a local sex toy distributor, you're not paying manufacturing cost. You're paying for their warehouse, their staff, their marketing, their profit margin, and their own supplier's markup.

I've seen retailers pay $25-30 for vibrators that cost $8-10 to manufacture. That $20 difference per unit means you need to sell at significantly higher retail prices to achieve reasonable margins—which makes you less competitive.

Small orders also create operational inefficiency. You're constantly reordering, managing multiple small shipments, and spending time on procurement rather than business growth. One client calculated she spent 6-8 hours monthly on reordering from her local wholesaler. At her hourly rate, that represented real opportunity cost.

Inventory Risk vs. Market Testing

The counterargument for low MOQs centers on inventory risk—and it's valid for specific scenarios. If you're testing an entirely new product category with zero market validation, betting $3,000 on 500 units could be foolish.

But here's what I've observed: Most new adult product retailers aren't entering a vacuum. You have data from competitors, market research, and customer feedback. The question isn't "will vibrators sell" but "which vibrators sell best for my specific customer base."

This is where our white label approach at VF Pleasure provides the sweet spot. Instead of custom manufacturing a completely untested product, you're selecting from proven designs that already succeed in the market. We know the performance data on our private label sex toys—which materials work, which features resonate, which price points convert.

You're not gambling on an unknown product. You're investing in market-validated designs with your unique brand positioning.

Strategic Capital Allocation

Let's talk about how serious entrepreneurs think about MOQs and capital deployment. This perspective transformed how I advise my clients.

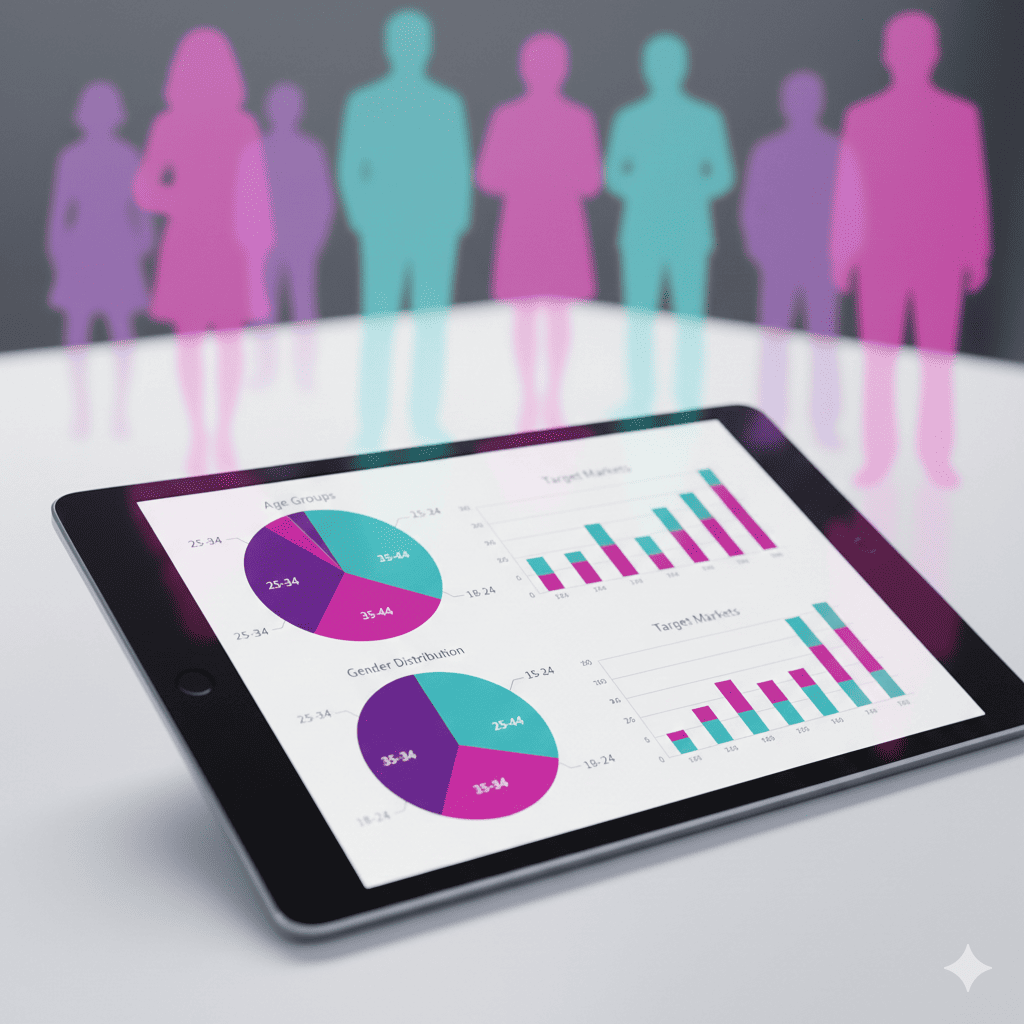

Comparing Investment Scenarios

Imagine you have $5,000 to invest in inventory. Here are three scenarios:

Scenario A: Local Wholesaler

- 200 mixed units at $25 average

- Total investment: $5,000

- Retail value at 100% markup: $10,000

- Gross profit: $5,000

Scenario B: Trading Company

- 350 mixed units at $14 average

- Total investment: $4,900

- Retail value at 100% markup: $17,150

- Gross profit: $12,250

Scenario C: Direct Manufacturer (VF Pleasure White Label)

- 600 units across 3 designs at $8 average

- Total investment: $4,800

- Retail value at 100% markup: $28,800

- Gross profit: $24,000

The numbers speak clearly. With nearly identical capital investment, Scenario C provides 4.8x the gross profit potential of Scenario A.

But wait—won't 600 units take much longer to sell than 200 units? Not necessarily. Your pricing flexibility changes everything.

With the local wholesaler model, you must maintain high margins just to justify the business. With factory-direct pricing, you can:

- Offer competitive retail pricing

- Run promotional discounts without eroding profitability

- Bundle products creatively

- Provide volume discounts to B2B customers

I've watched clients using our white label program outsell their competitors by 2-3x because they could price aggressively while maintaining healthy margins. Their higher inventory velocity meant those 600 units sold in similar timeframes to a competitor's 200 units—but with dramatically better profitability.

What Makes a Manufacturer Partnership Work for Small Orders?

Not all manufacturers accommodate lower volume clients, and frankly, not all should. Mass production facilities optimized for 10,000+ unit runs can't efficiently serve 500-unit orders. The question becomes: what distinguishes manufacturers who successfully serve emerging brands?

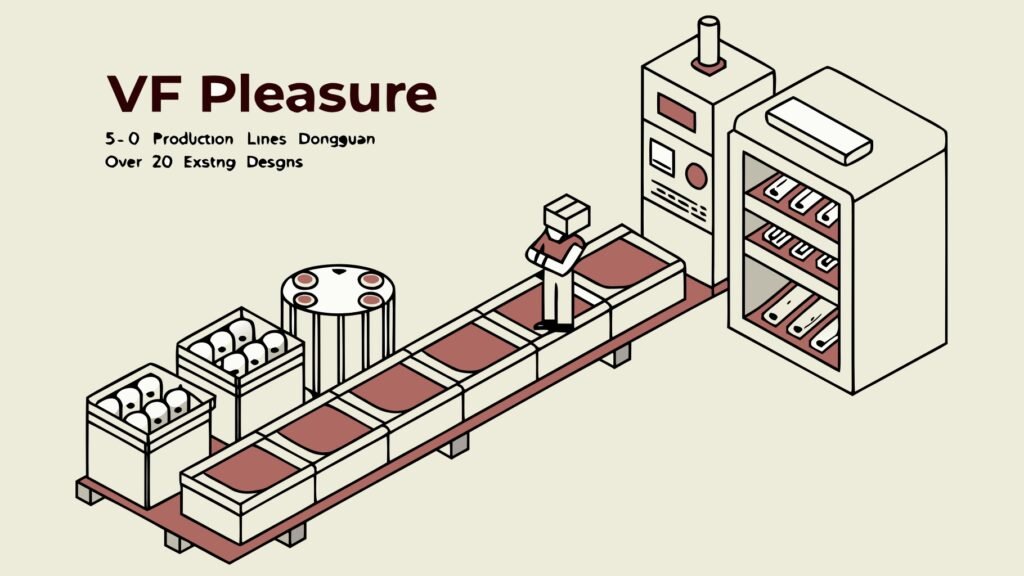

Successful small-order manufacturer partnerships require flexible production systems, extensive existing mold libraries, and a genuine commitment to client growth. At VF Pleasure, our 5-10 production lines in DongGuan allow us to run smaller batches economically while our 200+ existing designs eliminate custom tooling costs that typically create high MOQ barriers.

Production Infrastructure That Supports Scalability

Our DongGuan facility represents 15 years of strategic investment. We didn't build it overnight, and the configuration specifically addresses the pain points I experienced when I started in this industry.

Multi-Line Production Advantages

Operating 5-10 dedicated production lines creates flexibility that single-line factories can't match. When you place a 500-unit order, we don't shut down our entire facility—we allocate one line for a specific production window.

This matters for several reasons:

First, your lead times stay reasonable (typically 15-25 days) even with smaller orders. Single-line facilities might make you wait 60-90 days until they accumulate enough orders to justify a production run.

Second, quality control remains consistent. We're not switching between radically different products every few hours. Each line specializes in specific product categories—one handles female sex toys, another focuses on male adult toys, and so on.

Third, it allows us to maintain economic efficiency even at lower volumes. Our per-unit production costs on a 500-unit run typically sit only 15-20% higher than a 5,000-unit run—unlike many manufacturers where small batches cost 50-100% more per unit.

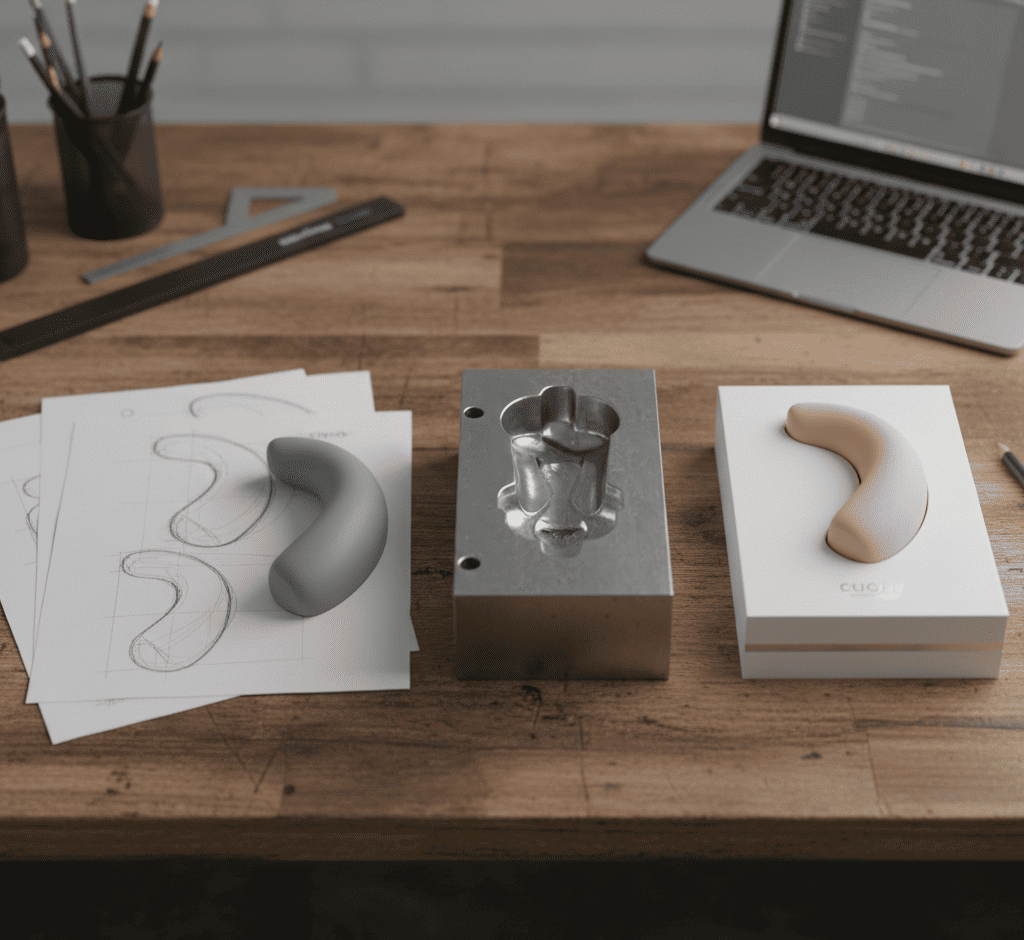

The Mold Library Advantage

Here's where the economics really shift in favor of direct manufacturer relationships for white label products. Custom mold development costs typically run $3,000-8,000 depending on complexity. This expense alone creates high MOQ requirements—manufacturers need to amortize that investment across enough units to make economic sense.

Our extensive mold library eliminates this barrier entirely. We've already made the investment. Those 200+ existing designs represent millions of dollars in development and tooling costs, spread across years of production.

When you choose a white label product, you're essentially licensing access to this design library. Your only customization costs involve branding, packaging, and any color variations you want. These represent minimal per-unit expenses.

I recently calculated this for a client. If she pursued custom OEM development for her specific vibrator design:

- Mold development: $5,000

- Minimum 2,000 units to justify tooling

- Total investment: $17,000-20,000

With our white label approach:

- Zero mold costs

- 500-unit minimum

- Total investment: $4,500-6,000

She launched her brand three months earlier and with 70% less capital at risk. When her initial products succeeded, she had both the capital and market validation to invest in custom OEM development.

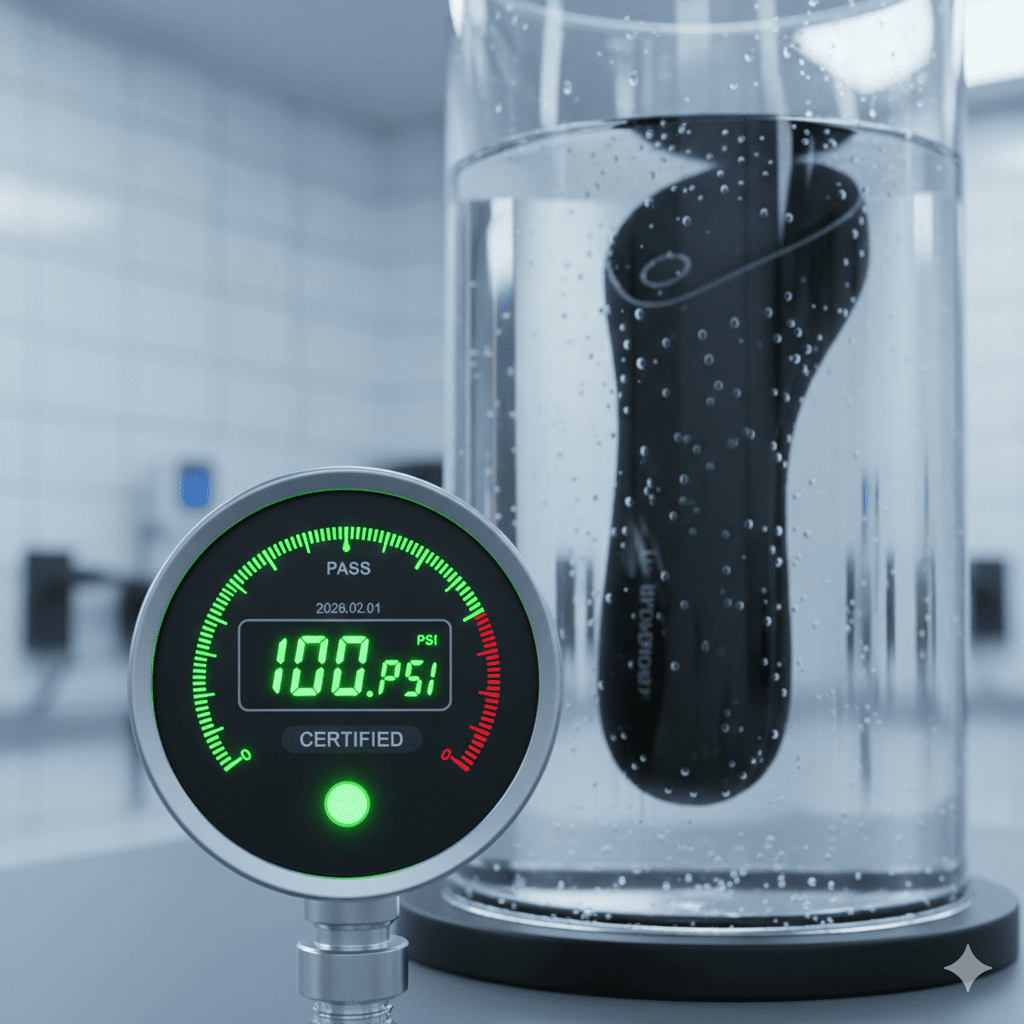

Quality Systems and Material Standards

Working with an adult toy factory requires understanding that not all manufacturers maintain equivalent quality standards. This becomes especially critical in an industry where products interact intimately with human bodies.

At VF Pleasure, we exclusively use food-grade platinum silicone for our silicone products, along with body-safe ABS plastic. These aren't just marketing terms—they represent specific material certifications and safety testing.

Our Shenzhen R&D center conducts ongoing material testing and quality verification. Each production batch undergoes multiple quality checkpoints:

- Raw material verification

- In-process production inspection

- Post-production function testing

- Packaging and labeling verification

- Random sample performance testing

For small-order clients, this matters tremendously. You lack the resources to conduct extensive product testing yourself. You're trusting your supplier's quality systems to protect both your customers and your brand reputation.

I've seen retailers destroyed by quality failures—products that broke within days, materials that caused irritation, motors that died immediately. These weren't necessarily intentional quality failures. They resulted from manufacturers who lacked proper systems and cut corners to reduce costs.

When you're ordering 500 units rather than 5,000, you might assume quality matters less because your exposure is limited. The opposite is true. Quality failures on your first 500 units kill your brand before it gains traction. You get no second chance with disappointed customers.

Should I Start with Local Wholesalers or Go Direct to Manufacturers?

This question deserves a nuanced answer because the "right" choice genuinely depends on your specific situation, goals, and constraints. I've seen both approaches succeed—and both approaches fail when misapplied.

Start with local wholesalers if: you have under $1,000 to invest, need immediate inventory (within days), want to test multiple categories simultaneously with minimal commitment, or lack storage space. Go direct to manufacturers if: you can invest $3,000-5,000, have identified 2-3 core products you're confident will sell, want to build a branded business (not just reselling), and can wait 4-6 weeks for production and shipping.

The Local Wholesaler Launch Strategy

Let me be clear: I'm a manufacturer advocating for direct partnerships, but I genuinely respect the local wholesaler approach for specific scenarios. It serves a real purpose in the market ecosystem.

When Local Makes Sense

You're testing the viability of an adult products business entirely. You've never sold these products, don't fully understand customer preferences, and want to validate that you can actually execute sales and marketing before making larger commitments.

In this case, spending $500-1,000 with a local sex toy wholesaler provides invaluable market education. You'll learn:

- Which products generate customer interest

- What price points work in your market

- How to handle customer questions and concerns

- What marketing channels drive actual sales

- Whether you even enjoy this business

These lessons justify the premium pricing from local wholesalers. You're paying for education and flexibility, not just products.

I worked with Jennifer, who started exactly this way. She bought 30 mixed units from a local sex toy wholesale supplier for about $750. Within 90 days, she'd sold through her inventory and identified three product categories that consistently sold well.

She then came to VF Pleasure. We created a white label program focusing on those three categories—vibrators, couples toys, and thrusting sex toys. Her second order represented $4,500 in inventory but at roughly half the per-unit cost. Her business scaled from there.

The Hybrid Approach

Some smart retailers use both channels strategically. They maintain a base inventory from direct manufacturer relationships while supplementing with fast-moving items or trendy products from local wholesalers.

This hybrid model provides stability (factory-direct pricing on core products) with agility (quick access to trending items or seasonal products). The key is maintaining clear financial tracking so you understand which channel drives actual profitability.

The Direct Manufacturer Partnership Strategy

For entrepreneurs ready to build a real brand rather than just reselling commodity products, direct manufacturer partnerships offer the only viable long-term path.

Building Sustainable Competitive Advantages

Here's the uncomfortable truth about simply reselling wholesale products: you have zero competitive moats. Anyone can access the same wholesalers, buy the same products, and undercut your pricing.

Your only competitive advantages become:

- Marketing effectiveness

- Customer service quality

- Geographic convenience

These matter, but they're not sustainable long-term advantages. Better-funded competitors can outspend you on marketing, hire better customer service teams, or offer faster shipping.

Branded products manufactured through direct partnerships create actual barriers to competition:

- Product differentiation: Your specific designs, features, and quality standards can't be exactly replicated

- Price control: Factory-direct economics let you maintain healthy margins while pricing competitively

- Brand equity: Customers develop loyalty to your brand, not just product categories

- Intellectual property: Custom designs and branding create legal protection

I've watched this play out repeatedly. Resellers using local wholesalers face constant price pressure and customer churn. Branded businesses with manufacturer partnerships build customer loyalty and can raise prices over time as brand value increases.

One client started reselling generic wholesale dildos at rock-bottom margins. After two years of struggling, she partnered with us for a private label line. Within 18 months, her branded products commanded 30% price premiums over generic competitors and her customer retention rate doubled.

Navigating the Initial Investment Hurdle

The psychological barrier of a larger initial investment stops many entrepreneurs from pursuing direct manufacturer relationships. I understand this—$4,000-5,000 feels like a significant bet, especially compared to $500-1,000.

But let's reframe the investment:

$5,000 with local wholesaler:

- 200 units

- Sell at $50 retail = $10,000 revenue

- Net profit: $5,000 (100% markup)

- Months to recoup investment: 2-4 months (assuming steady sales)

$5,000 with manufacturer direct:

- 600 units

- Sell at $40 retail = $24,000 revenue

- Net profit: $19,000 (380% return)

- Months to recoup investment: 2-4 months (same sales velocity)

The manufacturer relationship doesn't require faster sales velocity to recoup investment—it requires similar velocity while generating 4x the profit.

Additionally, consider reinvestment dynamics. With the wholesaler model, your $5,000 profit allows you to place a similar-sized reorder. With the manufacturer model, your $19,000 profit allows you to expand into additional product lines, invest in marketing, or increase inventory depth.

The compounding effect over 12-24 months becomes dramatic. This isn't just about individual transactions—it's about growth trajectories.

What Other Factors Should I Consider Beyond MOQ?

Minimum order quantities represent just one variable in a complex decision matrix. Experienced procurement professionals like my typical customer, David, know that MOQ becomes almost irrelevant if other factors don't align. Let me share what really matters.

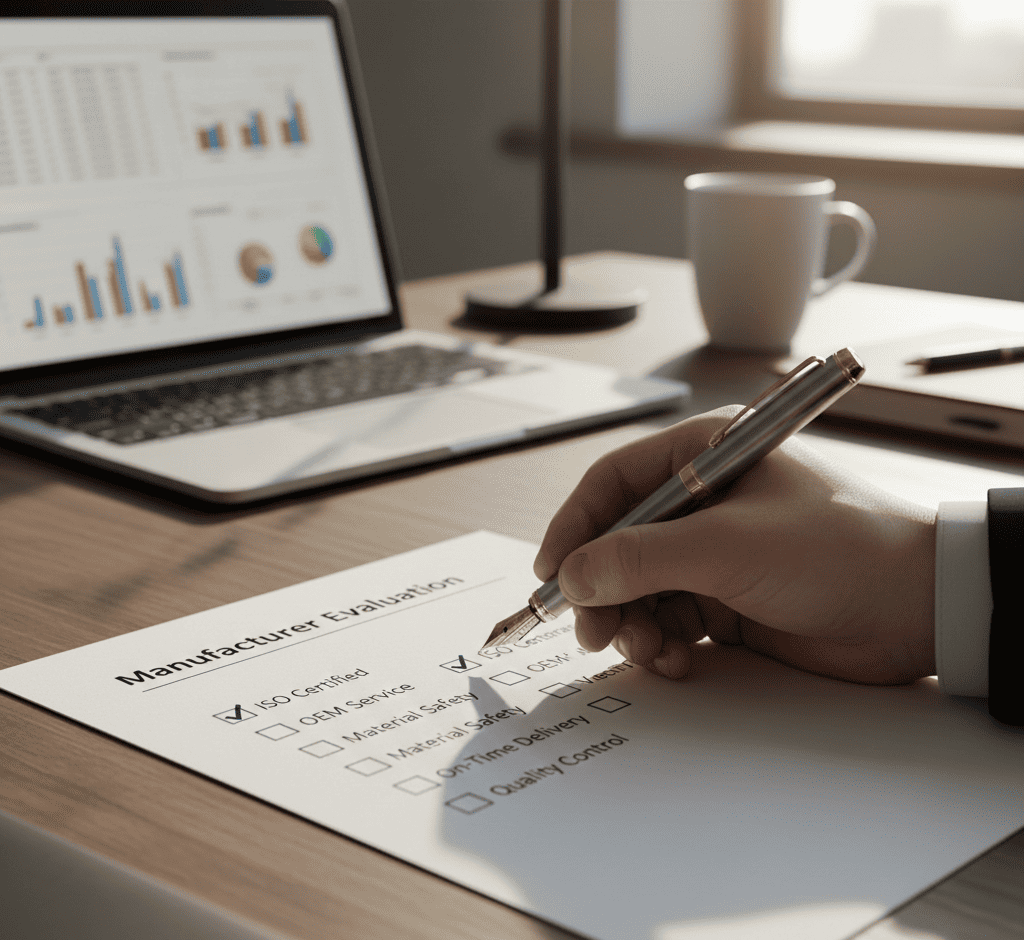

Beyond MOQ, prioritize: total landed cost (including shipping, duties, payment terms), lead times and reorder flexibility, quality consistency and product certifications, supplier communication and problem-solving capability, and long-term partnership potential. The "cheapest" supplier often becomes the most expensive when hidden costs and operational headaches emerge.

Total Landed Cost Reality

I meet clients constantly focused exclusively on per-unit FOB pricing. They'll call three manufacturers, compare quoted prices, and choose the lowest number. Then they're shocked when their "cheap" supplier ends up costing more overall.

Breaking Down True Costs

Let's examine what actually determines your total landed cost:

Product FOB Price: This is the baseline—what you pay at the factory door.

International Shipping: For small orders (under 100kg), air freight typically costs $5-8 per kilogram. Sea freight becomes economical only at higher volumes (500kg+). Many new importers underestimate this dramatically.

Customs Duties and Taxes: Adult products face varying import duties depending on your country. In the US, rates range from 0-6.8% depending on specific product classification. Then add state/local sales taxes if applicable.

Payment Processing Fees: International wire transfers cost $25-50 per transaction. PayPal or Alibaba Trade Assurance charges 3-5%. These fees matter more on smaller orders.

Quality Control and Testing: If you're serious about quality, you need third-party inspection services or product testing. This might run $200-500 per order for small batches.

Insurance: International shipping insurance typically costs 1-2% of product value.

I recently helped a client compare two suppliers:

Supplier A (Lower FOB Price)

- FOB: $7/unit × 500 units = $3,500

- Air freight (50kg): $400

- Customs (4%): $140

- Payment fee (wire transfer): $35

- Total landed cost: $4,075 ($8.15/unit)

Supplier B (Higher FOB Price—VF Pleasure)

- FOB: $8/unit × 500 units = $4,000

- Air freight (45kg—better packaging): $360

- Customs (4%): $160

- Payment fee: $35

- Total landed cost: $4,555 ($9.11/unit)

On paper, Supplier A looked better. But here's what the numbers didn't show:

Supplier A had a 30% defect rate on the first shipment. My client needed to scrap 150 units ($1,275 loss). True landed cost jumped to $10.70/unit for usable products.

Our VF Pleasure products had a 2% defect rate. After factoring in actual usable products, our true landed cost was $9.30/unit—13% cheaper than Supplier A despite higher FOB pricing.

This pattern repeats constantly. The lowest quoted price rarely equals the lowest total cost.

Lead Times and Supply Chain Reliability

In e-commerce, inventory velocity drives profitability. Products sitting in warehouses generate zero revenue while incurring storage costs. Lead time reliability becomes a critical factor that many new retailers underestimate.

Production and Shipping Timelines

At VF Pleasure, our typical production timeline for white label products runs:

- Order confirmation to production start: 3-5 days

- Production cycle: 12-18 days

- Quality inspection and packaging: 2-4 days

- Shipping preparation: 1-2 days

- Air freight: 5-7 days

- Customs clearance: 2-5 days

Total time from order to delivery: approximately 25-35 days for air freight.

Sea freight extends this by 20-30 days but reduces per-unit shipping costs significantly. For initial orders, I typically recommend air freight despite higher costs because faster inventory turnover improves cash flow.

More important than average lead times is reliability. A manufacturer promising 20 days but delivering in 35 days creates planning chaos. You've marketed products that haven't arrived. You've disappointed customers. You've lost sales momentum.

I've built VF Pleasure's reputation partly on lead time reliability. We build buffer time into our estimates and communicate proactively when any delays emerge. This seems basic, but you'd be amazed how many manufacturers overpromise and underdeliver.

Communication and Problem-Solving Partnership

This factor might seem soft compared to pricing and lead times, but it determines whether your relationship succeeds long-term. Manufacturing problems will occur. Shipping delays happen. Customer feedback requires product adjustments.

Responsive Communication Standards

Our team at VF Pleasure maintains response windows of 4-8 hours during business days. We've invested in English-fluent customer service staff specifically because we understand communication gaps create costly mistakes.

I've seen relationships fail because of communication problems:

- Client orders 500 units of Product A; manufacturer produces Product B due to miscommunication

- Customer wants specific packaging changes; manufacturer doesn't understand requirements

- Quality issue emerges; manufacturer responds slowly or defensively

These failures cost both parties money and damage relationships beyond repair.

When evaluating manufacturers, test their communication before placing orders:

- How quickly do they respond to inquiries?

- Do they ask clarifying questions or make assumptions?

- Can they explain technical details clearly?

- Do they proactively suggest solutions or just execute orders?

I encourage potential clients to treat initial conversations as communication audits. If we can't communicate effectively when trying to win your business, we certainly won't communicate effectively when problems arise.

Certifications and Compliance

This matters more in adult products than many other industries because products interact intimately with human bodies. The wrong materials cause serious health problems. Manufacturing standards affect safety.

At VF Pleasure, we maintain:

- ISO 9001 quality management certification

- FDA-registered materials and manufacturing processes

- CE certification for European markets

- Material safety testing documentation

These aren't just badges to display on websites—they represent actual operational standards and third-party verification.

For clients selling in regulated markets (EU, US, Canada, Australia), proper certifications protect against costly product recalls, legal liability, and market access barriers.

I've watched competitors face devastating consequences from certification failures—products seized at customs, forced recalls costing tens of thousands of dollars, legal actions from customers harmed by unsafe materials.

The "expensive" manufacturer with proper certifications becomes the cheap option when you avoid these catastrophic failures.

Conclusion

Finding adult novelty wholesale sources with low MOQs requires balancing immediate constraints with long-term business goals. Start with local wholesalers for market testing with minimal capital, but transition to direct manufacturer partnerships when you're ready to build a sustainable branded business with real competitive advantages.