Your manufacturer choice determines your brand's future. I've run a sex toy factory in Dongguan for 15 years, and I've watched brands collapse from one bad material decision. The wrong silicone sex toy manufacturer doesn't just hurt your margins—it destroys customer trust, triggers product recalls, and exposes you to liability claims that can end your business overnight.

Choosing a silicone sex toy manufacturer requires verifying food-grade platinum silicone certifications, assessing overmolding technical capabilities, evaluating R&D problem-solving skills, confirming quality control protocols, and ensuring transparent material sourcing. Prioritize adult toy manufacturers who treat material integrity as non-negotiable, offer engineering collaboration during prototyping, maintain documented quality systems, and demonstrate long-term partnership commitment over lowest-price quotations.

Most brands make manufacturer decisions based on price per unit. That's backwards. Your manufacturer is your technical partner, quality gatekeeper, and brand reputation guardian. When I meet new clients at VF Pleasure, they often focus on MOQs and unit costs. I redirect them to material certificates and engineering capabilities because those factors determine whether their brand exists in five years.

What Makes Silicone Material Quality Non-Negotiable?

Material safety defines your entire brand. One contaminated batch can trigger recalls, lawsuits, and permanent reputation damage. I've rejected entire shipments from competing sex toys factory operations because the silicone smelled wrong—even when it came with "certificates."

Food-grade platinum silicone must meet FDA standards for body-safe contact, contain zero phthalates or toxic additives, resist bacterial growth, maintain stability across temperature ranges, and provide proper shore hardness for intended use. Inferior alternatives include peroxide-cured silicone (which releases formaldehyde), silicone mixed with TPE fillers (which degrades quickly), and recycled silicone compounds (which contain unknown contaminants). Demand raw material certifications from recognized testing laboratories—not supplier declarations—and physically test samples before committing to production.

When samples arrive at your office, conduct immediate sensory tests. Food-grade platinum silicone has virtually no odor. If you smell anything chemical, burnt rubber, or plastic-like, reject it. That smell indicates contamination or improper curing. I train our quality team to trust their noses because certifications can be faked, but chemistry cannot lie.

Understanding Silicone Curing Methods

Two primary curing methods exist: platinum and peroxide. Platinum-cured silicone uses platinum catalysts and produces medical-grade results with no harmful byproducts. Peroxide-cured silicone uses organic peroxides that release formaldehyde during curing—a known carcinogen. Many budget custom sex toys factory operations use peroxide curing because it's cheaper and faster.

I've toured facilities claiming "medical-grade" silicone while using peroxide processes. The giveaway is curing time—peroxide cures in minutes versus hours for platinum. Ask your sex toy manufacturer specific questions about curing chemistry. If they dodge or provide vague answers, they're likely cutting corners.

Shore Hardness and User Experience

Silicone shore hardness1 ranges from 00-50A (soft) to 50-90A (firm). Body-safe products typically use 10-40A depending on application. Female sex toys requiring flexibility need softer compounds around 10-20A. Male adult toys might use 30-40A for better structural integrity.

Your sex toys manufacturer should discuss shore hardness1 during design. We test multiple hardness levels during prototyping because small variations dramatically affect user experience. A clitoral stimulator at 15A feels luxurious; at 25A it feels harsh. These details separate premium adult toy manufacturers from generic operations.

Material Additive Testing

Pure platinum silicone contains only silicone polymers, platinum catalyst, and FDA-approved pigments. Some manufacturers add fillers to reduce costs—talc, chalk, or recycled materials. These additives compromise safety and durability. Demand third-party testing for heavy metals, phthalates, and volatile organic compounds.

At VF Pleasure's facility, we test every material batch before production. Our lab runs spectrometry analysis to verify composition matches supplier specifications. This costs money, but it protects our clients from the catastrophic expense of recalls.

How to Assess Technical Manufacturing Capabilities?

Material quality means nothing without manufacturing precision. The best silicone becomes dangerous products if molding, assembly, or finishing processes introduce contamination or defects. Technical capabilities reveal whether an adult toys factory can consistently deliver safe products.

Advanced manufacturing capabilities include multi-cavity injection molding for consistent part quality, overmolding technology bonding silicone to ABS cores without gaps, automated quality inspection systems, cleanroom assembly environments, and destructive testing protocols. Evaluate these through facility tours, production samples showing cross-sections of overmolded joints, documentation of process controls, and discussions with engineers about handling complex geometries and material transitions.

Overmolding represents the highest technical challenge in adult product manufacturing. This process bonds soft silicone to rigid ABS plastic cores—creating products that combine flexible external surfaces with internal structure for motors and electronics. Poor overmolding creates microscopic gaps where bacteria accumulate, turning your product into a health hazard.

Overmolding Technical Standards

Proper overmolding requires precise temperature control within 5°C2, exact injection timing measured in milliseconds, and specialized bonding agents that create molecular adhesion between materials. I've seen competing vibrator factory operations produce overmolded parts with visible separation lines—clear evidence of inadequate process control.

Ask your potential sex toy manufacturer to show cross-sections of overmolded components. At our facility, we cut finished samples in half to demonstrate complete material bonding. You should see zero gaps, consistent wall thickness, and smooth transitions between materials. Any air pockets or separation means the process is deficient.

Mold Design and Maintenance

Manufacturing consistency depends on mold quality. Premium injection molds cost $5,000-15,000 because they're precision-machined from hardened steel with complex cooling channels and perfect surface finishes. Budget molds use softer metals that wear quickly, producing dimensional variations across production runs.

We maintain detailed maintenance logs for every mold in our tooling room. Each mold gets inspected after specific shot counts and refurbished before quality degrades. When evaluating adult toy manufacturers, ask about their mold maintenance protocols. Vague answers indicate poor process control.

Quality Control Integration

Manufacturing quality isn't inspected afterward—it's built into every process step. Our production lines include automated vision systems3 that check part dimensions in real-time, ejecting defective pieces before they reach assembly. We perform go/no-go testing on critical dimensions and run functional tests on every electronic component before integration.

Tour your potential custom adult toys partner's facility. Watch their actual production. Are workers performing in-process checks or just running machines? Do they document quality data or rely on visual inspection? Modern sex toys manufacturer china operations should show you statistical process control charts[4] proving capability.

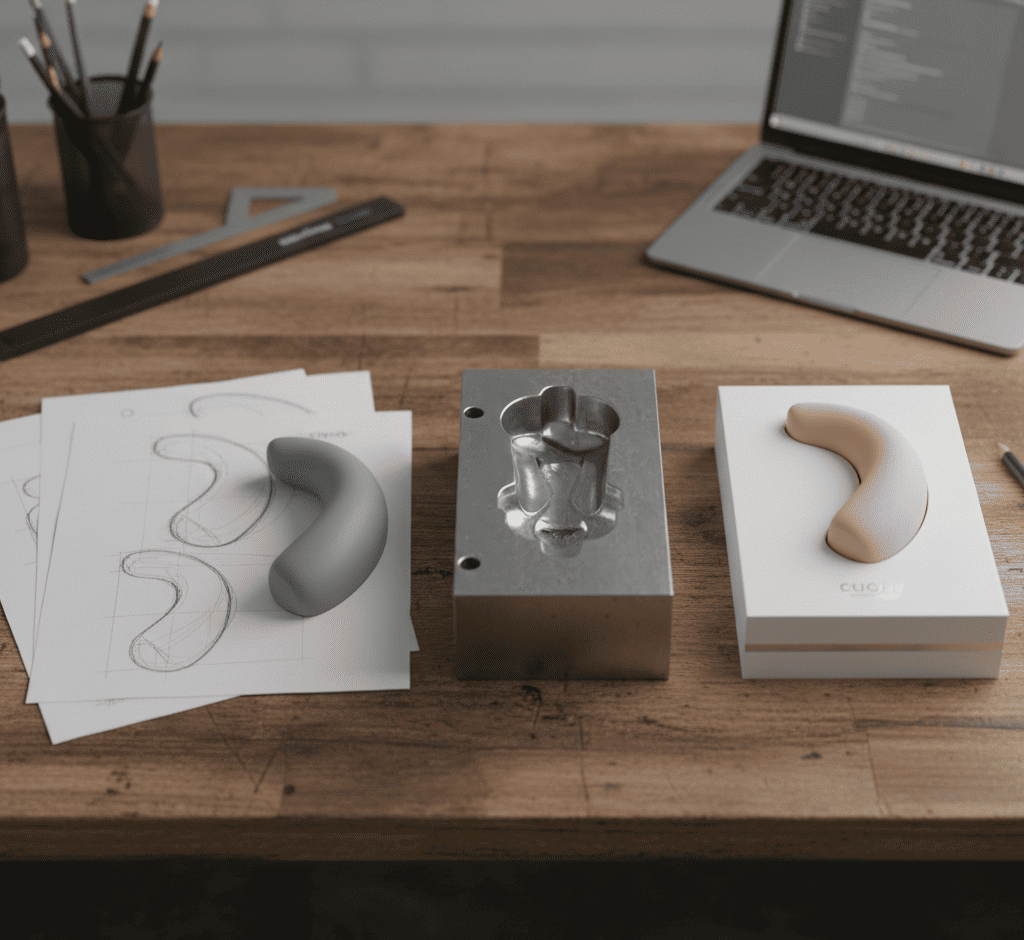

Why Engineering Collaboration Matters During Development?

Your manufacturer should improve your designs, not just execute them. Engineering collaboration during prototyping identifies problems before they become expensive production issues. This partnership mindset separates strategic adult toy suppliers from transactional vendors.

Engineering collaboration includes design for manufacturability reviews that optimize part geometry for consistent molding, material selection guidance based on functional requirements, cost reduction suggestions that maintain quality, regulatory compliance consultation, and failure mode analysis preventing field issues. Effective sex toy factory partners assign dedicated engineers to your project, schedule regular technical reviews, provide detailed manufacturing specifications, and proactively suggest improvements even when current designs are producible.

![]()

I remember a brand bringing us a thrusting sex toy design with beautiful CAD models. Our engineer immediately spotted a problem—the proposed wall thickness would create sink marks during molding, ruining surface finish. We suggested minor geometry changes that eliminated the issue while actually reducing material costs. That's the value of true engineering partnership.

Design for Manufacturability4

Products that look perfect in CAD might be impossible to manufacture consistently. Undercuts require complex mold actions that increase costs and failure points. Sharp internal corners create stress concentrations causing premature failures. Thin sections might not fill completely during injection.

Our engineering team reviews every design for manufacturability before quoting. We explain which features create production challenges and suggest alternatives. Sometimes a 2mm radius change eliminates an expensive mold mechanism. These optimizations save money and improve reliability—but only if your oem adult toys manufacturer has engineers who care about your success.

Prototype Iteration Strategy5

Prototyping shouldn't be "make my design and ship it." Effective prototyping involves multiple iterations testing different approaches. We typically produce three prototype rounds: first to validate basic functionality, second to optimize materials and assembly, third to confirm production-ready design.

Each iteration includes destructive testing. We purposely break prototypes to find failure modes. Where do stress fractures initiate? Can users accidentally open battery compartments? Does silicone delaminate under extreme use? Finding these issues in prototyping costs hundreds; discovering them after production costs thousands.

Cost Engineering Without Compromising Quality6

Budget constraints are real, but cost reduction should never sacrifice safety or core functionality. Smart engineering finds savings in secondary areas. We might suggest a simpler button mechanism that's easier to assemble. Or optimize packaging dimensions to reduce shipping costs. Or identify a motor that performs identically but costs 15% less.

I discourage clients from competing solely on price because that race only goes down. Instead, we engineer value—finding ways to deliver better products at competitive prices through manufacturing efficiency, not material compromises.

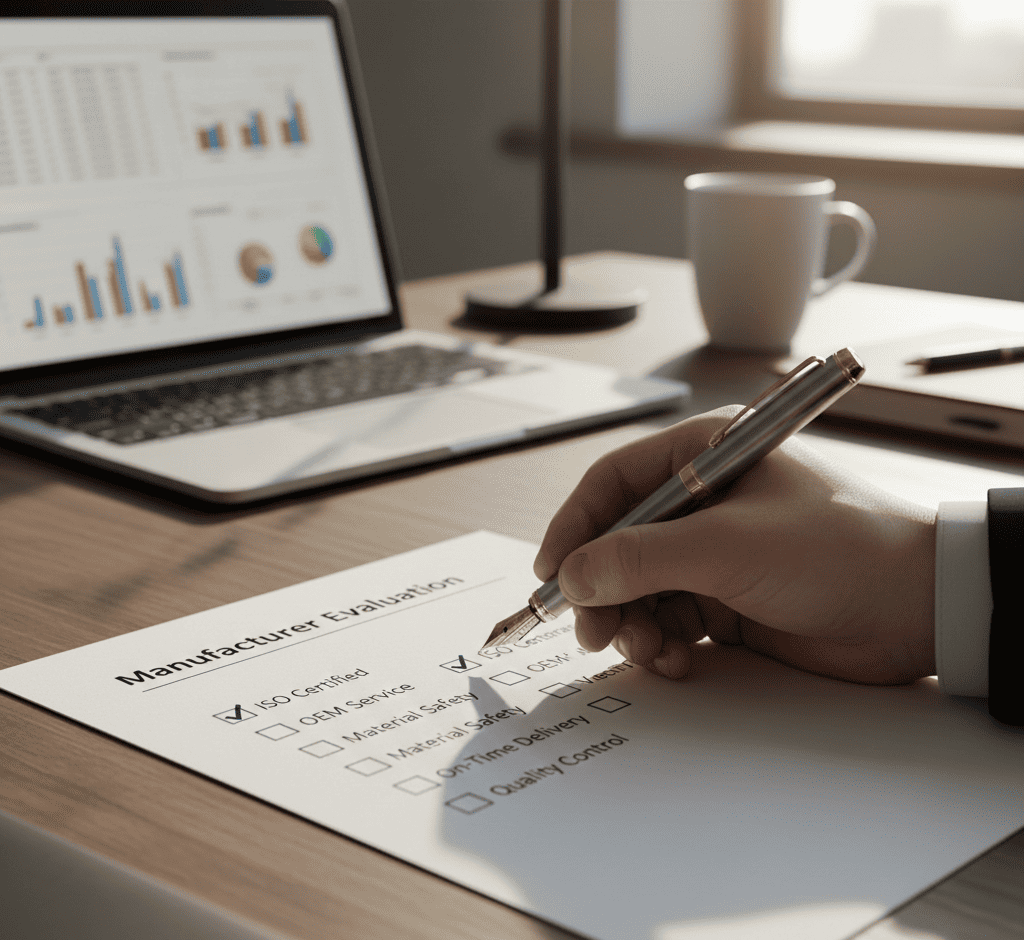

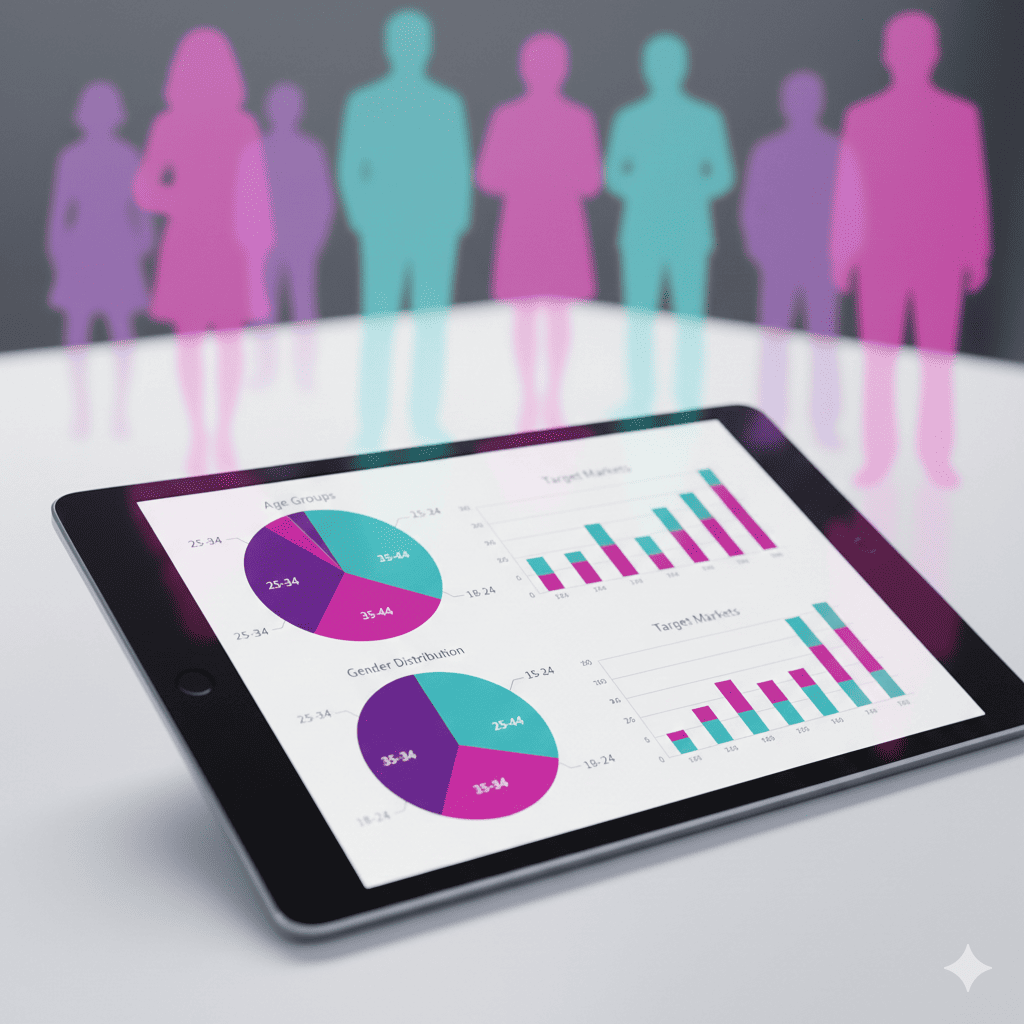

How to Verify Quality Control Systems?

Quality control separates professional adult toy manufacturers from backyard operations. Documented quality systems ensure every product meets specifications regardless of which operator runs the machine or which day production occurs.

Comprehensive quality control requires incoming material inspection with documented test results, in-process monitoring at critical control points, functional testing of every finished product, statistical process control tracking dimensional consistency, documented corrective action procedures when defects occur, and traceability systems linking finished products to specific material batches. Verify these systems exist through facility audits, review of actual quality records, discussion of specific defect scenarios and response procedures, and examination of rejected product segregation processes.

![]()

Quality documentation reveals how seriously a sex toys factory takes consistency. We maintain detailed records of every material batch, production run, and test result. If a customer reports an issue, we can trace that exact unit back to raw materials, production date, operator, and mold cavity. This traceability is essential for professional operations but rare among budget manufacturers.

Incoming Material Verification

Quality starts before production begins. When silicone arrives from our suppliers, we don't trust their certificates—we test it ourselves. Our lab verifies shore hardness, tear strength, and chemical composition match specifications. Rejected materials get returned immediately, even if it delays production.

Ask potential sex toy manufacturer partners how they handle incoming material inspection. If their answer is "we trust our suppliers," that's a red flag. Professional operations verify everything because even good suppliers occasionally ship defective batches.

In-Process Control Points

We define critical control points in every production process—stages where defects might occur. For injection molding, we monitor melt temperature, injection pressure, and cooling time. For assembly, we check component alignment and fastener torque. Each control point has documented specifications and trained operators performing checks.

Visit your potential oem adult products partner during active production. Are operators checking parts or just running machines? Do they have measuring tools at their stations? Are there documented procedures posted? These details indicate whether quality is systematic or accidental.

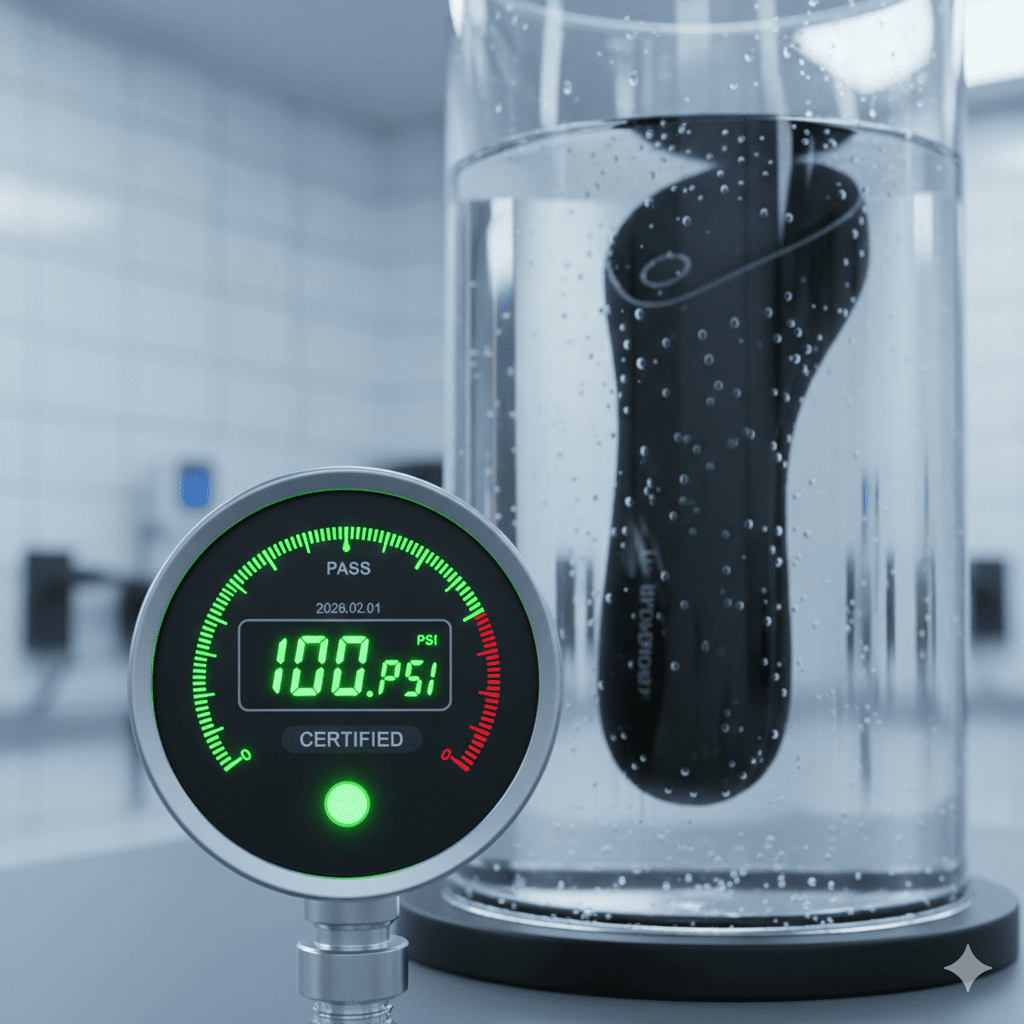

Functional Testing Protocols

Every electronic sex toy leaving our facility gets functionally tested. We power on each unit, verify all vibration patterns, confirm battery charging, and test control responsiveness. This sounds obvious, but many wholesale sex toys operations skip functional testing to save time, shipping a percentage of non-functional products.

Ask what percentage of production undergoes functional testing. The correct answer is 100%. Anything less means your customers will discover defects instead of the manufacturer.

Corrective Action Documentation

Defects will occur—the question is how manufacturers respond. Professional operations document every defect, investigate root causes, implement corrective actions, and verify effectiveness. We maintain a corrective action log accessible to clients showing exactly how we handle quality issues.

Request to see your potential partner's corrective action records from the past six months. If they refuse or claim they have no defects, they're either lying or not tracking quality properly. Both scenarios are problematic.

What Red Flags Indicate Problematic Manufacturers?

Certain behaviors reveal manufacturers who will cause problems. I've seen these patterns repeatedly over 15 years. Recognizing red flags early saves you from costly mistakes and protects your brand reputation.

Major red flags include refusing facility tours or providing limited access, inability to produce material certifications from recognized testing labs, requesting large deposits before sampling, providing only marketing materials instead of technical specifications, lacking dedicated engineering support, offering prices significantly below market rates, showing no interest in your brand strategy or target market, and demonstrating poor communication responsiveness. Additionally, watch for generic sample products that seem identical to competitors, vague answers about manufacturing processes, and pressure to commit to large MOQs before prototyping.

The biggest red flag is price that seems too good to be true. Premium silicone, precision manufacturing, and proper quality control have real costs. When adult toy wholesaler prices undercut market rates by 40-50%, they're either cutting corners on materials, using inferior processes, or planning to bait-and-switch after you've committed.

Facility Access Restrictions

Legitimate sex toys manufacturers welcome facility tours. We show clients our entire operation—from raw material storage through final packaging. If a manufacturer refuses tours or only shows selected areas, they're hiding something. Maybe they don't actually manufacture products. Maybe their facility conditions are unacceptable. Either way, limited access indicates problems.

I've had brands tell me their previous supplier refused factory visits, claiming "trade secrets." That's nonsense. Manufacturing processes aren't secret—execution quality is what matters. Transparency indicates confidence.

Certificate Authenticity Issues

Material certificates should come from independent testing laboratories—SGS, Intertek, Bureau Veritas, or similar recognized organizations. Some manufacturers provide "certificates" that are actually just supplier declarations or internal test results. These have no credibility.

Request specific test reports with dates, sample identifications, and laboratory contact information. Then verify those labs actually performed the tests. We've caught competitors using forged certificates by simply calling the listed laboratories.

Communication and Responsiveness

How manufacturers communicate during sales reveals how they'll communicate during production. Do they respond to technical questions with detailed answers or vague reassurances? Do they proactively raise potential issues or only mention problems after they've occurred? Clear, prompt, honest communication indicates a partner who values your success.

We assign dedicated account managers to every client at VF Pleasure. Your manager has direct access to our production floor, engineering team, and quality control. When you email a question, you get answers within 24 hours—usually within hours. That responsiveness reflects our commitment to partnership, not just transactions.

Why Long-Term Partnership Approach Protects Your Investment?

Manufacturing relationships should span years, not individual orders. Long-term partnerships enable continuous improvement, shared investment in tooling, volume-based efficiencies, and collaborative product development that creates sustainable competitive advantages.

Long-term manufacturer partnerships deliver cumulative value through shared knowledge of your brand requirements, amortized tooling costs across multiple products, priority production scheduling during peak seasons, collaborative new product development leveraging manufacturer expertise, flexible terms as trust builds, and continuous process optimization reducing costs while maintaining quality. Choose private label sex toys manufacturers who demonstrate commitment to your growth—evidenced by flexible scaling, investment in your success, and strategic consultation beyond basic production services.

I've worked with some brands for over a decade. We've launched dozens of products together, weathered market changes, and built mutual success. Those relationships generate value far exceeding any single order. We understand their brand positioning, know their customer preferences, and proactively suggest products matching their market strategy.

Tooling Investment Strategy

Custom molds cost thousands of dollars. In transactional relationships, you pay full tooling costs upfront and own molds that might never be used for additional orders. In partnerships, we structure tooling investments differently—potentially amortizing costs across projected volumes or offering free mold development for certain order commitments.

We maintain client-owned tooling in our facility at no storage cost. When you're ready to reorder, your molds are ready for production within days. This flexibility is only possible in long-term partnerships where both parties trust the relationship continues.

Continuous Product Optimization

After initial production, we don't stop improving. Our engineering team reviews products periodically, identifying opportunities to reduce costs, improve durability, or enhance features. Maybe a new motor offers better performance at lower cost. Perhaps a material supplier developed improved silicone compounds. We proactively bring these opportunities to partners.

One brand's vibrator design originally used three separate molded parts. Over two years, we optimized it to two parts through revised mold design—reducing assembly time and cost while improving water sealing. That optimization saved them thousands across subsequent production runs.

Market Trend Collaboration

Operating exclusively in adult products manufacturing, we see market trends across all our clients. When certain features gain popularity, we inform partners early. If we notice regulatory changes affecting specific materials, we alert everyone immediately. This collective intelligence benefits our entire partner network.

Recently we noticed increasing demand for app-controlled products. We proactively developed Bluetooth integration capabilities and offered those to existing partners before they requested them. Several launched connected product lines months ahead of competitors because we anticipated the trend.

Crisis Support and Flexibility

Business challenges arise—unexpected demand spikes, cash flow constraints, competitive pressures. Long-term partners weather these together. We've adjusted payment terms during tight quarters for established clients. We've expedited production for urgent market opportunities. We've collaborated on cost-reduction projects when margin pressures increased.

These flexibilities only exist in genuine partnerships. Transactional relationships focus on individual order terms; strategic partnerships focus on mutual long-term success.

How VF Pleasure Delivers Comprehensive Manufacturing Partnership?

After 15 years building VF Pleasure's capabilities in Dongguan, we've structured our entire operation around long-term client success. Our facility houses 5-10 dedicated production lines, in-house engineering teams, material testing laboratories, and comprehensive quality systems—all focused exclusively on adult product manufacturing.

VF Pleasure provides complete sex toy manufacturer services including food-grade platinum silicone sourcing with full certification, advanced overmolding capabilities, flexible MOQs starting at 500-1000 units, dedicated engineering support throughout development, comprehensive quality control with documented traceability, and strategic consultation on product positioning and market trends. Our Dongguan manufacturing facility specializes in custom vibrators, female sex toys, male products, thrusting mechanisms, and couples toys—delivering the technical depth and manufacturing precision required for premium private label brands.

We've deliberately positioned ourselves as partners, not vendors. Our business model depends on client success because satisfied partners generate repeat orders, referrals, and collaborative product development that benefits everyone. This alignment of interests ensures we treat your brand reputation as carefully as our own.

Our Material Standards

Every silicone compound we use meets FDA food-contact standards. We source from certified suppliers and test every batch independently. Our material library includes various shore hardnesses, colors, and specialty compounds like antimicrobial or temperature-reactive formulations. During product development, we help you select optimal materials balancing performance, cost, and user experience.

Engineering and R&D Capabilities

Our engineering team includes mechanical designers, electronics engineers, and industrial designers. We handle complete product development from concept sketches through production-ready designs. Whether you need OEM execution of your designs or ODM development from scratch, we provide appropriate engineering support.

Quality Assurance Systems

We maintain ISO 9001 quality management systems with documented procedures for every process. Our quality team performs incoming material inspection, in-process monitoring, functional testing, and final inspection before packaging. Every product includes traceability codes linking it to specific production records.

Partnership Approach

We limit our client portfolio to ensure adequate attention for each partner. You're not order number 47 in a queue—you're a strategic partner with dedicated resources. We schedule regular business reviews discussing market trends, product performance, and future opportunities. This collaborative approach has built lasting relationships generating mutual success.

Conclusion

Choosing your silicone sex toy manufacturer determines your brand's future. Prioritize material integrity, technical capabilities, engineering collaboration, quality systems, and partnership commitment over unit price to build a sustainable, reputable brand.

-

Understanding shore hardness is crucial for selecting the right silicone products, impacting comfort and usability. ↩ ↩

-

Understanding the significance of precise temperature control can enhance your product quality and manufacturing efficiency. ↩

-

Discover how automated systems can enhance quality assurance and reduce defects in production processes. ↩

-

Understanding Design for Manufacturability can help you create products that are easier and more cost-effective to produce. ↩

-

Exploring Prototype Iteration Strategy can enhance your prototyping process, leading to better product outcomes and reduced costs. ↩

-

Learning about Cost Engineering can help you maintain quality while effectively managing your budget in product development. ↩