I've manufactured custom adult toys for over 15 years. The biggest frustration I hear from wholesale buyers? Sky-high minimum order quantities that kill innovation before it starts.

Custom adult toy manufacturing works best with flexible MOQs, rapid prototyping (7-14 days), and full OEM/ODM support. At VF Pleasure, we start at 100-500 pieces, compared to industry standards of 5,000+ units, letting brands test markets before committing to massive inventory.

Last month, a California retailer called me in panic. Their previous manufacturer demanded 10,000 units for a custom vibrator design. They needed to test the market first. I solved their problem with a 300-piece trial run.

- 1 What Makes OEM Adult Toy Manufacturing Different From ODM?

- 2 How Low Can MOQs Actually Go For Custom Sex Toys?

- 3 What Does "Fast Prototyping" Actually Mean In Adult Toy Manufacturing?

- 4 How Do I Actually Start A Custom Adult Toy Project?

- 5 What About Customization Options Beyond Basic Design?

- 6 Why Work With VF Pleasure Instead Of Other Manufacturers?

- 7 What Questions Should I Ask Any Custom Manufacturer?

- 8 Conclusion

What Makes OEM Adult Toy Manufacturing Different From ODM?

I get this question constantly. Buyers mix up these terms, and it costs them money. Let me clear this up right now.

OEM (Original Equipment Manufacturer) means you bring designs to us for production. ODM (Original Design Manufacturer) means we design products for your brand. Most successful partnerships blend both approaches for maximum market advantage.

The Real Difference In Practice

OEM works when you've already got detailed specifications. You know exactly what you want. Maybe you hired a designer. Perhaps you're copying a successful product with improvements.

I manufacture your vision. You own the design. I handle production.

ODM flips this completely. You come to me with a market problem. "My customers want stronger clitoral stimulation." Or "I need a couples toy under $30 retail."

My design team creates solutions. We develop prototypes. You get exclusive rights to the final product.

Here's what most people miss: hybrid partnerships work best.

Last year, I worked with a European distributor launching a premium [female sex toys](https://www.reddit.com/r/TooAfraidToAsk/comments/1io8g75/ladies_what_is_unabashedly_the_best_vibratorsex/)1 line. They had basic sketches (OEM starting point). My team refined the motor placement, adjusted the curve angle, and suggested medical-grade silicone upgrades (ODM improvements).

Result? Their product hit $2 million in first-year sales.

Why This Matters For Your Bottom Line

OEM costs less upfront. You're paying for manufacturing only. But you carry all design risk.

ODM costs more initially. My design team invests 40-80 hours in development. But you get proven market solutions.

At VF Pleasure, I recommend starting with ODM for your hero products. Build your catalog with OEM for variations. This strategy gives you market differentiation2 while controlling costs.

The typical margin improvement? 25-40% compared to catalog products.

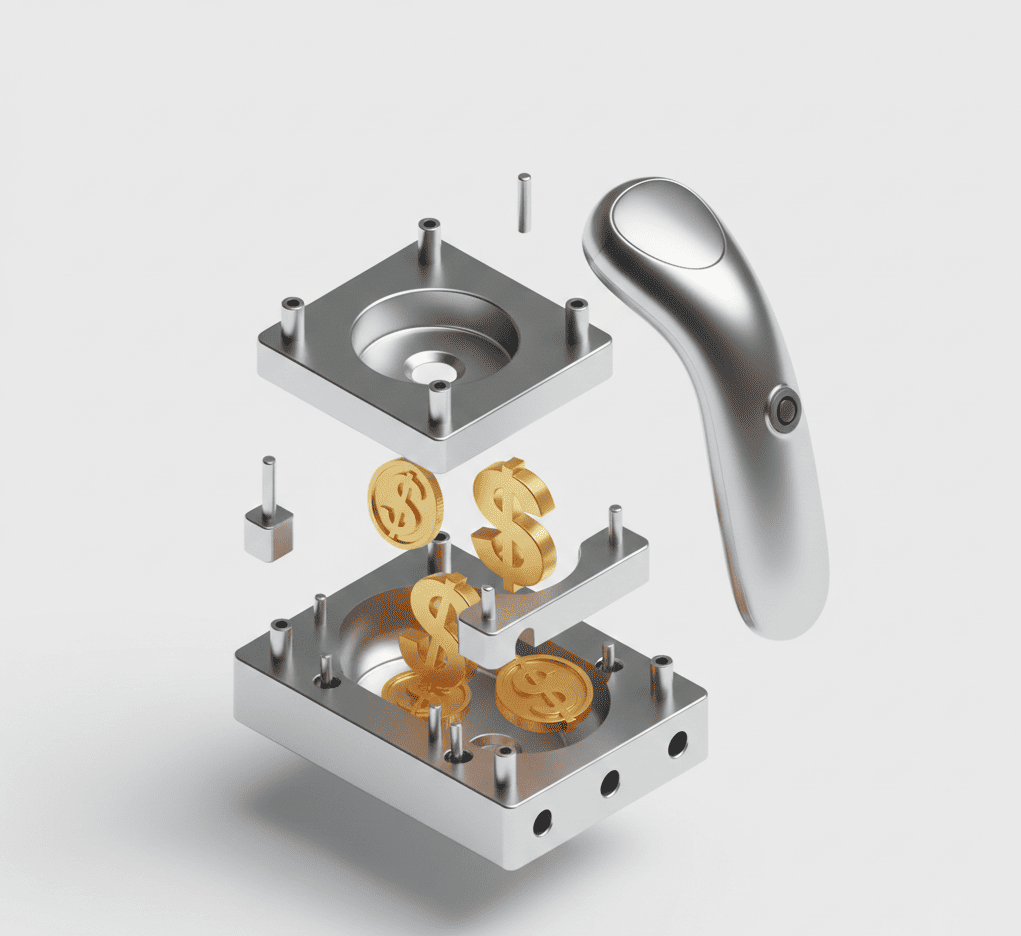

How Low Can MOQs Actually Go For Custom Sex Toys?

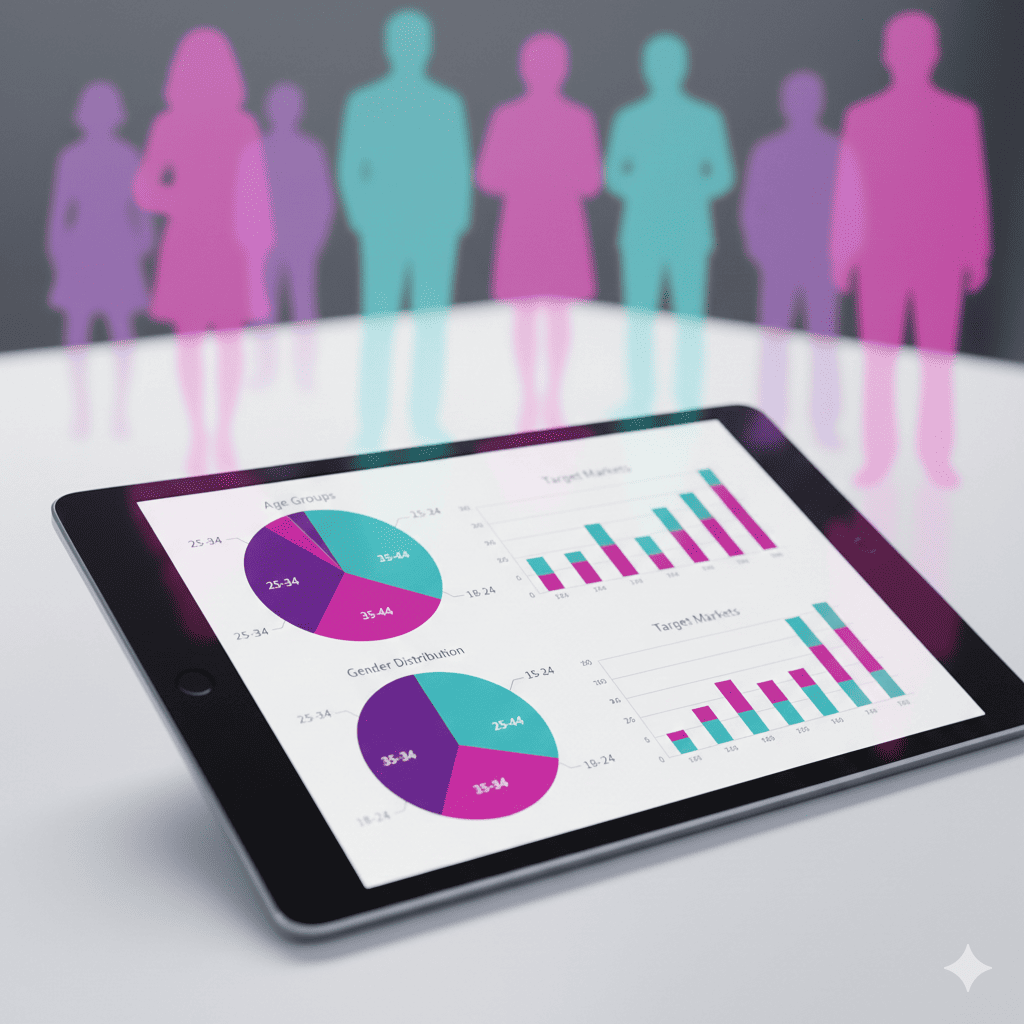

Industry standard? 5,000-10,000 pieces minimum. That's $50,000-$150,000 tied up in untested inventory. I've seen this destroy growing brands.

Custom adult toy MOQs at VF Pleasure start at 100-500 pieces depending on complexity. Simple vibrators begin at 100 units. Multi-function products with custom tooling require 500 pieces. This flexibility lets wholesale buyers test markets with $5,000-$15,000 investments instead of six-figure commitments.

The Real Cost Of High MOQs

Three months ago, a Texas wholesaler contacted me. Their previous sex toy manufacturer required 8,000 units for a custom thrusting sex toy.

Total investment: $120,000.

Market response: lukewarm.

They sold 2,400 pieces in nine months. The remaining 5,600 units sat in their warehouse. At $15 per unit in capital costs, they lost $84,000 in tied-up cash.

When they came to me for their next product, we started with 300 pieces. Investment: $7,500. Market tested positive. We scaled to 2,000 units for the full launch.

How I Keep MOQs Low Without Sacrificing Quality

My DongGuang facility runs differently than traditional factories. I maintain five production lines specifically for prototyping and small batches.

Line capacity: 50-500 pieces daily.

Most factories can't do this profitably. Their setup costs are too high. They need volume to justify tooling and changeovers.

I've structured my operation for flexibility. My tooling library contains over 200 standard molds. Customization happens through inserts, not complete new tools.

For wholesale sex toys buyers, this means faster launches with lower risk.

When Higher MOQs Make Sense

I'm honest with my clients. Ultra-low MOQs aren't always the best strategy.

If you've validated your market? Scale up to 2,000-5,000 units. Your per-unit cost drops 30-45%. Your margins improve dramatically.

The sweet spot: start at 300-500 pieces for market validation. Scale to 2,000+ for full launch. This two-phase approach balances risk with profitability.

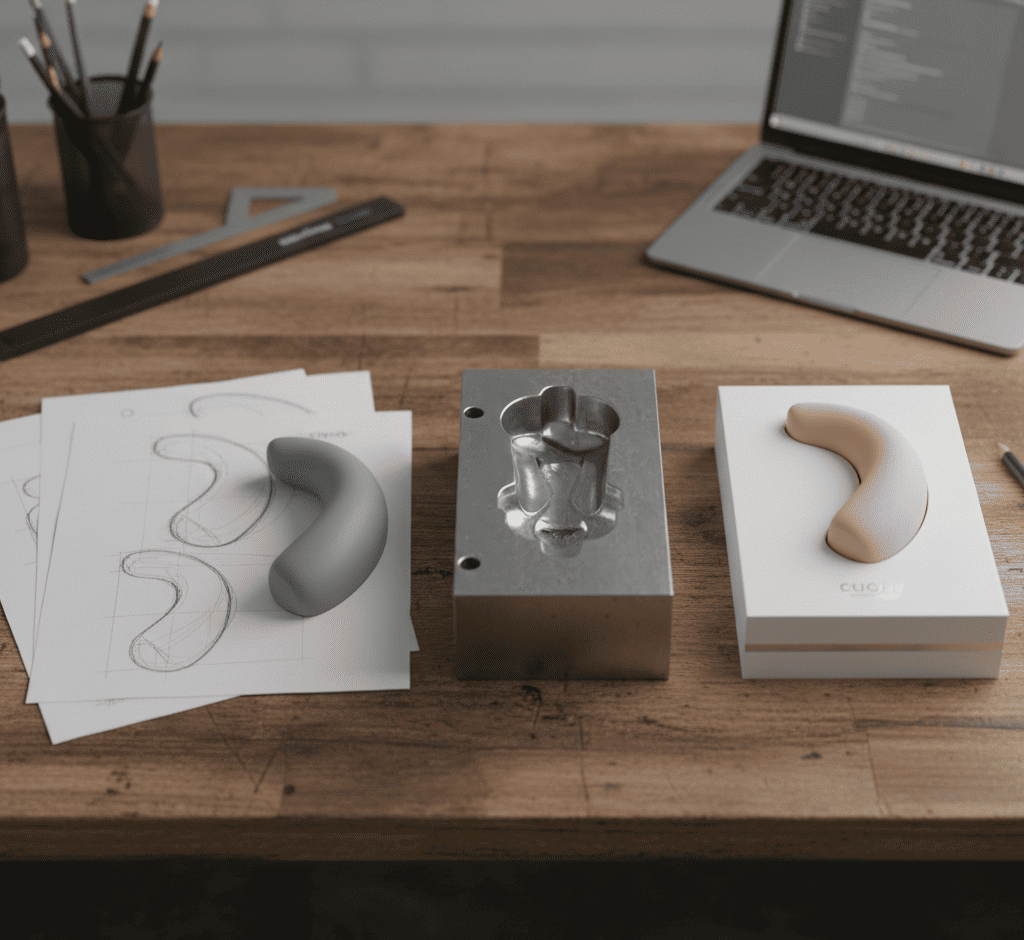

What Does "Fast Prototyping" Actually Mean In Adult Toy Manufacturing?

Industry standard: 6-8 weeks for initial samples. I've always thought this was absurd. Markets move too quickly now.

Fast prototyping at VF Pleasure means functional samples in 7-14 days. Our in-house tooling capabilities, material libraries, and dedicated R&D team eliminate typical delays. For urgent projects, we've delivered working prototypes in 72 hours, though 10 days is more realistic for optimal results.

My Prototyping Process Breakdown

Day 1-2: Design refinement. My team converts your concepts into technical specifications. We identify potential manufacturing challenges immediately.

Day 3-5: Material selection and initial fabrication. We pull from our silicone library (15+ formulations) and start building.

Day 6-8: Motor integration and electronics assembly. This is where most delays happen at other factories. I keep components in stock.

Day 9-10: Testing and refinement. Every prototype gets functionality testing before shipping.

Most manufacturers don't have in-house tooling. They outsource to specialty shops. This adds 2-4 weeks automatically.

My Shenzhen R&D center handles everything internally. CNC machining, silicone molding, electronics assembly—all under one roof.

Real Speed-To-Market Impact

Last quarter, a UK brand approached me with a seasonal opportunity. Valentine's Day launch. They contacted me December 15th.

Timeline: 8 weeks to full production.

I delivered prototypes December 28th. They approved January 5th. Full production completed February 1st.

Their products hit shelves February 10th. Peak Valentine's sales window.

Their previous manufacturer quoted 12-week lead times. Would've missed the entire seasonal opportunity.

The Technology Behind Fast Prototyping

My advantage comes from three specific investments:

First, digital design integration3. My team uses CAD modeling that connects directly to CNC machines. No manual programming delays.

Second, material inventory. I stock $200,000 in silicone, ABS plastic, and electronic components. Most factories order materials per project.

Third, dedicated prototype staff. I employ eight technicians exclusively for prototype development. They're not pulled away for production runs.

These investments cost me roughly $500,000 annually. But they generate $2-3 million in additional revenue from clients who value speed.

How Do I Actually Start A Custom Adult Toy Project?

The process intimidates most first-time buyers. I've simplified this over the years. Here's exactly how it works at VF Pleasure.

Starting a custom adult toy project requires: market positioning clarity, basic design concept, target retail price, and timeline expectations. Initial consultations take 30-60 minutes. I provide quotes within 48 hours, include prototype costs, tooling fees, and per-unit pricing at different volume levels.

Step 1: The Discovery Call

I need to understand your market. Who's your customer? What price point? What's your differentiation strategy?

This isn't busywork. These questions determine material choices, feature complexity, and production methods.

For example: premium positioning means platinum silicone and brushed metal accents. Budget positioning means body-safe ABS with simpler motors.

Step 2: Concept Development

You might have detailed drawings. Or maybe just a rough sketch. Both work fine.

My design team converts your ideas into 3D renderings. We add technical specifications. You see exactly what the final product will look like.

Revision rounds: typically 2-3 cycles. Each takes 2-3 days.

Step 3: Prototype Production

Once you approve the design, I start building. This is where my fast prototyping capabilities4 shine.

You receive a functional sample in 10-14 days. Not a mockup—a working product you can actually test.

Most buyers order 2-3 prototypes. One for testing. One for photography. One for backup.

Step 4: Refinement And Final Approval

Testing reveals improvements. Motor positioning needs adjustment. Silicone texture needs refinement. Button placement feels awkward.

I make these changes quickly. Second-generation prototypes arrive in 5-7 days.

Final approval triggers full production setup.

Step 5: Production And Quality Control

Production timelines depend on order quantity:

- 100-500 units: 2-3 weeks

- 500-2,000 units: 3-4 weeks

- 2,000-5,000 units: 4-6 weeks

Every unit gets functionality testing5. I maintain 0.3% defect rates. Industry average is 2-5%.

Your products ship with certification documents, user manuals, and packaging ready for retail.

What About Customization Options Beyond Basic Design?

Product design is just the starting point. Real brand differentiation happens in the details. I've learned this over hundreds of projects.

Customization extends to packaging design, user manuals, material selection, motor specifications, charging systems, and app integration. At VF Pleasure, we handle everything from concept through final packaging, eliminating the need to coordinate multiple vendors while maintaining complete brand control.

Packaging That Sells

I see too many brands ignore packaging. This is a mistake.

Packaging communicates quality before the product is even opened. Premium boxes with magnetic closures suggest luxury. Recyclable cardboard positions you as eco-conscious.

My design team creates custom packaging at no additional fee for orders over 1,000 units. We handle printing, assembly, and quality control.

Standard turnaround: 2-3 weeks after product approval.

Material Choices That Matter

Medical-grade silicone is my default recommendation. It's body-safe, durable, and feels premium.

But it's not always the right choice.

Budget lines work better with body-safe ABS. It's more affordable, allows brighter colors, and customers understand the value proposition.

Hybrid products combine both materials. Silicone contact surfaces with ABS bases. This balances cost with quality perception.

I stock 15 silicone formulations and 8 ABS colors. Custom colors are available at 500+ unit orders.

Motor And Electronics Customization

Motor selection dramatically affects user experience. I maintain relationships with three motor suppliers. Each specializes in different performance characteristics.

Quiet operation motors: Japanese suppliers. Higher cost but whisper-quiet.

Powerful motors: Chinese manufacturers. Best thrust-to-size ratio.

Budget motors: Domestic suppliers. Reliable performance at entry-level pricing.

Rechargeable vs. battery-powered? This choice impacts price, user convenience, and environmental positioning.

I recommend rechargeable for products over $30 retail. USB charging is now customer expectation at that price point.

App Integration And Smart Features

Connected toys are growing rapidly. I've added Bluetooth integration capabilities this year.

Development cost: $15,000-25,000 for custom apps.

Per-unit cost increase: $8-12 for Bluetooth-enabled products.

This makes sense for premium lines targeting tech-savvy customers. For mainstream products, it's often unnecessary complexity.

My advice: start simple. Add smart features once you've established market presence.

Why Work With VF Pleasure Instead Of Other Manufacturers?

I know you're comparing options. You should be. Here's what makes my service different.

VF Pleasure combines 15 years of manufacturing expertise with flexible MOQs, rapid prototyping, and full-service support from concept through shipping. Our integrated approach—design, manufacturing, packaging, and quality control—eliminates vendor coordination headaches while maintaining premium quality standards that support your brand positioning.

The Numbers That Matter

My clients typically see:

- 7-14 day prototype delivery6 vs. 6-8 week industry standard

- 100-500 piece MOQs vs. 5,000+ piece requirements elsewhere

- 25-40% higher margins from proprietary designs

- 0.3% defect rates vs. 2-5% industry average

These aren't marketing claims. They're operational realities from my production systems.

Beyond Manufacturing

I don't just make products. I help you build profitable product lines.

That means honest advice about market positioning7. Clear communication about costs and timelines. Proactive problem-solving when issues emerge.

Last month, a client's product had motor vibration at specific speeds. I didn't ship defective units. I identified the resonance frequency issue, adjusted the motor mounting, and delivered corrected products within 5 days.

No excuses. No delays. Just solutions.

The Partnership Approach

My best relationships last 5-10 years. They evolve from simple manufacturing to collaborative development.

You bring market insights. I bring production capabilities. Together, we create products that generate consistent profits.

Visit our About Us page to learn more about our team and facilities.

What Questions Should I Ask Any Custom Manufacturer?

Don't just take my word for anything. Here are the questions you should ask every potential manufacturing partner.

Essential Questions

"What's your actual MOQ, including all hidden requirements?"

Some factories advertise low MOQs but require high-volume commitments for preferred pricing or terms.

"How long does prototyping really take?"

Get specific timelines with date commitments. "4-6 weeks" means 8 weeks in practice at most factories.

"What happens if the prototype doesn't meet specifications?"

Revision policies vary dramatically. I include two revision rounds in my standard pricing.

"What certifications do your products carry?"

CE, RoHS, and FDA registrations matter for international sales. Verify these exist before committing.

"Can I visit your factory?"

Transparency indicates confidence. I welcome facility visits to our DongGuang production center.

The Red Flags

Vague pricing that "depends on specifications." You should get clear per-unit costs at different volumes.

Requiring payment before prototype delivery. Standard practice is 30% deposit, 70% on approval.

No references or portfolio examples. Established manufacturers have case studies and client testimonials.

Pressure to commit to high volumes immediately. Legitimate manufacturers understand you need market validation.

Conclusion

Custom manufacturing gives you market differentiation and premium margins. Choose partners who balance speed, flexibility, and quality. Start small, validate fast, scale smart.

-

Explore this link to discover top-rated female sex toys that can enhance pleasure and satisfaction. ↩

-

Learn about strategies for market differentiation to stand out in a competitive landscape and boost your sales. ↩

-

Exploring digital design integration can reveal innovative techniques that streamline your prototyping workflow and reduce lead times. ↩

-

Explore this link to understand how fast prototyping can accelerate your product development process and enhance innovation. ↩

-

Learn about functionality testing to ensure your products meet quality standards and reduce defect rates. ↩

-

Understanding prototype delivery can enhance your product development process and reduce time to market. ↩

-

Exploring market positioning strategies can significantly improve your product's market fit and profitability. ↩