Choosing the wrong manufacturing partnership can kill your adult toy retail business before it starts. Many retailers lose thousands betting on the wrong approach. Smart retailers understand these key differences to maximize profits and minimize risks.

OEM gives you complete design control and better margins (15-20% higher), while ODM offers faster market entry (60-90 days) with lower upfront costs. Your choice depends on brand maturity, budget, and risk tolerance.

After running VF Pleasure for 15 years and managing multiple production lines in DongGuang, I've watched countless retailers make costly mistakes with their manufacturing choices. Let me share what actually works in today's competitive market.

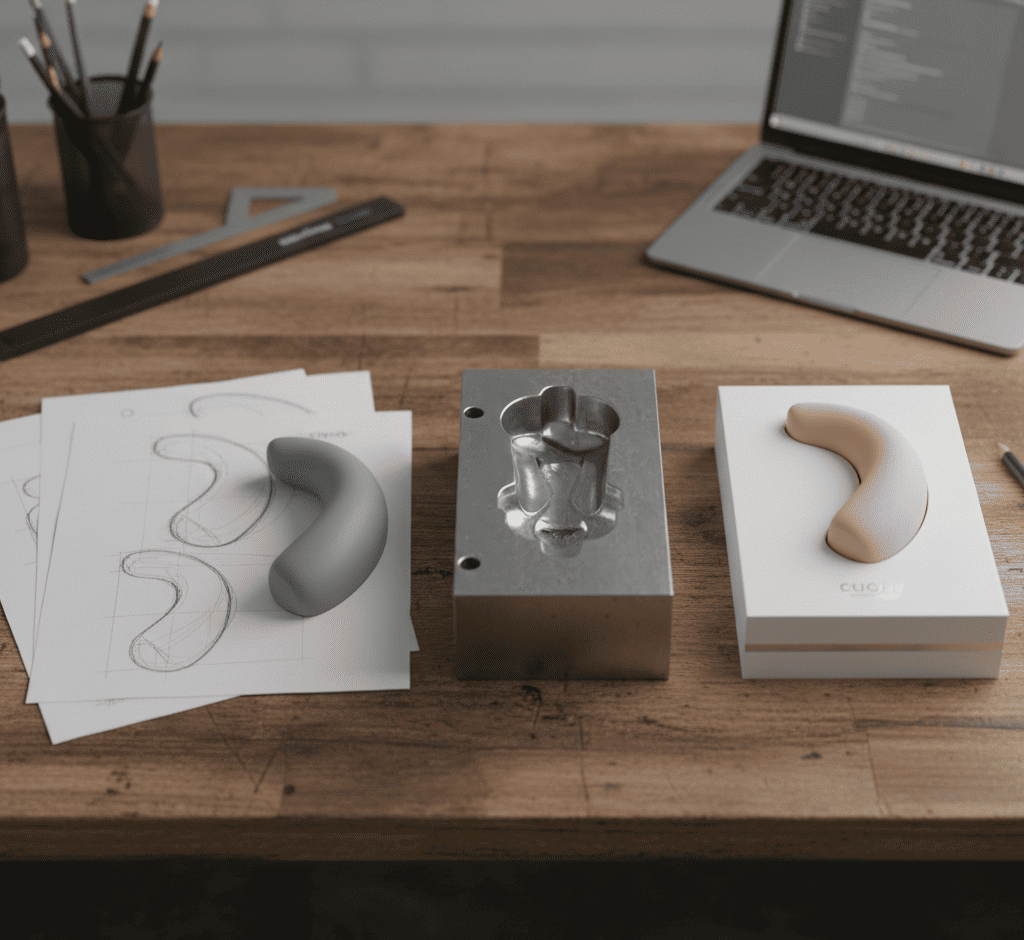

What Makes OEM Manufacturing Perfect for Established Brands?

Established retailers struggle with generic products that flood the market. They need unique offerings that command premium pricing. This creates serious competitive pressure.

OEM (Original Equipment Manufacturing) means you provide complete specifications while we handle production. You own the design IP, control quality standards, and maintain exclusive rights to your product concepts.

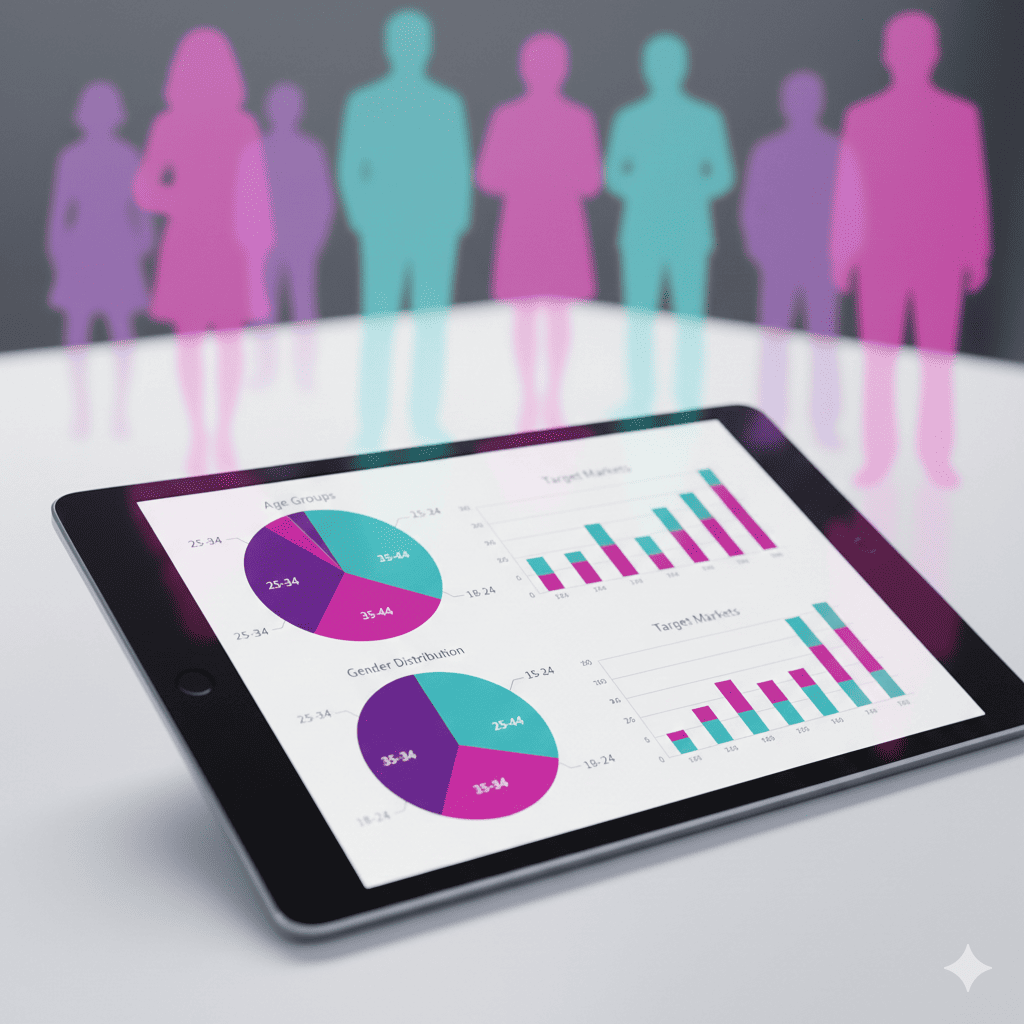

OEM manufacturing works best when you have clear market research and defined customer needs. I've seen retailers like Felle Reynolds succeed with OEM because they understand their target demographics deeply.

Your design team creates the specifications. Our custom sex toys factory transforms those ideas into market-ready products. You maintain complete control over materials, features, and branding elements.

The financial benefits are substantial. OEM partnerships1 typically deliver 15-20% better profit margins compared to ODM arrangements. You're not paying for shared design costs or licensing fees.

However, OEM requires significant upfront investment. Development costs range from $5,000 to $25,000 per product, depending on complexity. You also bear full market risk if the product doesn't perform as expected.

| OEM Advantages | OEM Challenges |

|---|---|

| Complete design control | High upfront investment |

| Better profit margins (15-20%) | Full market risk |

| Exclusive product rights | Longer development time |

| Scalable across suppliers | Requires design expertise |

| Premium positioning capability | Higher MOQ requirements |

The development timeline extends 4-6 months for complex products like thrusting sex toys or multi-function vibrators. This longer timeline can be problematic for seasonal launches or trend-based products.

When Does ODM Manufacturing Accelerate Your Market Entry?

New retailers face the challenge of entering competitive markets without proven products. They need quick wins to establish market presence. Time-to-market becomes critical for survival.

ODM (Original Design Manufacturing) leverages our existing designs, modified for your brand requirements. We handle design, development, and production while you focus on marketing and distribution.

ODM partnerships2 excel for retailers testing new market segments or innovative product categories. I recommend ODM when you're unsure about customer response or working with limited budgets.

Our design team already has proven concepts for female sex toys, male adult toys, and couples toys. We modify colors, materials, packaging, and minor features based on your brand guidelines.

The speed advantage is remarkable. ODM projects typically complete within 60-90 days versus 4-6 months for full OEM development. This rapid deployment lets you capture market opportunities and seasonal demand effectively.

Lower upfront costs make ODM attractive for emerging brands. Initial investment usually ranges $1,000-$5,000 per product variation. You're sharing development costs across multiple clients, which reduces individual financial burden.

However, ODM limits your differentiation options. Multiple retailers might offer similar products with minor variations. This can create price competition and margin pressure in your target markets.

| ODM Advantages | ODM Challenges |

|---|---|

| Fast market entry (60-90 days) | Limited differentiation |

| Lower upfront investment | Shared design ownership |

| Proven product concepts | Tighter profit margins |

| Reduced market risk | Less control over features |

| Lower MOQ requirements | Potential market overlap |

The financial trade-off is clear. ODM offers lower risk but typically delivers 8-12% lower profit margins compared to OEM arrangements. You're paying for convenience and reduced development risk.

How Do Hybrid Manufacturing Strategies Maximize Success?

Most retailers think they must choose exclusively between OEM and ODM approaches. This binary thinking limits growth potential and increases unnecessary risks. Smart retailers use both strategies strategically.

Hybrid manufacturing combines ODM for market testing with OEM for proven winners. Start with ODM to validate demand, then transition successful products to full OEM for better long-term profitability.

I recommend this hybrid approach for 80% of my retail clients. It minimizes financial risk while building your product portfolio systematically. You're not betting everything on unproven concepts.

Phase one involves ODM testing3 across multiple product categories. Launch 3-5 ODM products to identify which categories resonate with your customers. Monitor sales data, customer feedback, and return rates carefully.

Phase two transitions winning products to full OEM development. Products showing strong demand and positive feedback become candidates for exclusive OEM partnerships. You invest in custom designs for proven market opportunities.

This strategy works particularly well for [private label sex toys](https://vfpleasure.com/private-label-sex-toys-business-guide/)4 and wholesale operations. You can test market response without major capital commitments.

The timeline looks like this: ODM launch in months 1-3, data collection in months 4-9, OEM development for winners in months 10-15. By month 18, you have a portfolio of tested ODM products plus exclusive OEM winners.

Financial planning becomes more predictable. ODM products generate cash flow while you invest in OEM development. The successful ODM products essentially fund your transition to higher-margin OEM arrangements.

| Hybrid Strategy Benefits | Implementation Considerations |

|---|---|

| Risk minimization | Requires careful data tracking |

| Portfolio diversification | Multiple supplier relationships |

| Scalable investment approach | Longer overall timeline |

| Market validation before major investment | More complex inventory management |

| Cash flow from ODM funds OEM development | Requires strategic planning expertise |

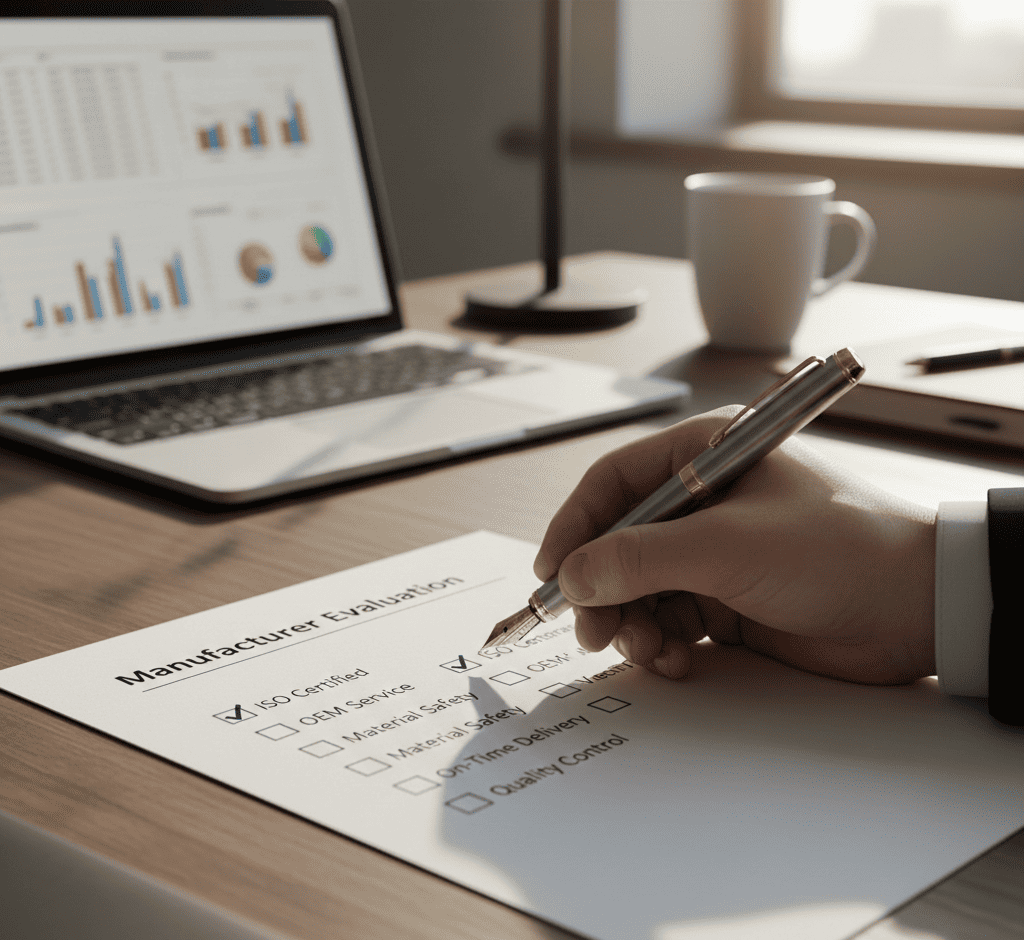

Your manufacturing partner must offer both OEM and ODM capabilities with transparent pricing structures. We provide detailed cost breakdowns for both approaches, helping you make informed decisions based on actual data rather than assumptions.

Conclusion

Choose OEM for proven concepts with established market demand, ODM for testing new opportunities quickly, or combine both strategies for maximum flexibility and reduced risk.

About me

I'm Sally from VF Pleasure, a leading adult toy manufacturer with 15 years of industry experience. Our facilities in DongGuang operate 5-10 production lines, serving retailers globally with comprehensive OEM/ODM services.

-

Explore this link to understand how OEM partnerships can enhance your profit margins and control over product design. ↩

-

Explore this link to understand how ODM partnerships can help retailers innovate and test new markets effectively. ↩

-

Learn about ODM testing to see how it can minimize risks and optimize your product portfolio effectively. ↩

-

Explore this link to understand how private label sex toys can enhance your product offerings and profitability. ↩