Finding reliable vibrator manufacturers in China who accept small orders feels impossible. Most factories demand huge minimum order quantities, leaving smaller brands stuck with limited options and generic products.

To launch custom vibrators with low MOQ in China, brands should identify specialized adult toy OEM factories, utilize existing molds with customization options, engage in joint development opportunities, leverage prototyping technologies, and build relationships with manufacturers focused on growing brands.

As someone who's worked with adult toy manufacturers in China for over a decade, I've seen countless brands struggle with this exact problem. The good news? There are effective strategies to overcome these barriers. I'll share insider approaches that have helped our partners successfully launch custom vibrators without massive initial investments.

- 1 What makes finding low MOQ vibrator manufacturers in China so challenging?

- 2 How can brands leverage existing molds for custom vibrators?

- 3 What joint development opportunities exist for small-batch vibrator production?

- 4 How are prototyping technologies changing small-batch vibrator manufacturing?

- 5 How important are manufacturer relationships in securing low MOQ arrangements?

- 6 Conclusion

What makes finding low MOQ vibrator manufacturers in China so challenging?

Most factories slam the door on small orders. When I first approached manufacturers, they quoted minimums of 3,000-5,000 units per SKU, making custom development financially impossible for new brands.

Finding low MOQ vibrator manufacturers is difficult because established factories focus on high-volume clients, custom mold development costs $5,000-15,000, production line reconfiguration is expensive, and smaller orders create inefficient production scheduling. These factors create significant barriers for new brands.

![]()

The barriers to small-batch vibrator manufacturing stem from several interconnected factors that affect both manufacturers and brands. At VF Pleasure, we've worked with numerous clients facing these challenges while trying to develop their vibrator product lines.

The economics of manufacturing create the most significant obstacle. Custom mold development for a new vibrator design typically costs between $5,000-15,000 depending on complexity. Manufacturers need to amortize this investment across production runs, making small orders financially unviable without charging prohibitive prices. Even when using existing molds, production line setup and reconfiguration costs remain relatively fixed whether producing 100 or 10,000 units.

Material sourcing adds another layer of complexity. Manufacturers purchase medical-grade silicone and other components in bulk to achieve favorable pricing. Small production runs often require the same materials but in quantities too small for optimal purchasing, driving up the per-unit cost significantly.

Quality control processes present another challenge. Each production batch requires testing procedures that consume time and resources regardless of batch size. For example, when we produce female sex toys, each batch requires waterproof testing, motor performance validation, and material safety checks. These processes have similar fixed costs whether testing 100 or 5,000 units.

The operational reality is that small batch production creates scheduling inefficiencies. Production managers must balance machine utilization, worker assignments, and production flow. Small runs cause more frequent line changes, increasing downtime and reducing overall factory output.

How can brands leverage existing molds for custom vibrators?

I once believed custom designs required completely new molds. Then I discovered that many factories maintain libraries of existing molds that can be modified for unique products.

Brands can leverage existing molds by selecting base designs from manufacturer catalogs, customizing through color changes, material adjustments, surface textures, motor specifications, and packaging differentiation. This approach reduces costs by 60-80% compared to fully custom development.

The strategic use of existing molds represents one of the most practical approaches for brands seeking customized products without high MOQs. At VF Pleasure, we maintain an extensive library of over 200 base designs that serve as starting points for customization.

The customization process typically follows a systematic approach that balances uniqueness with manufacturing efficiency:

Primary Customization Options for Existing Molds

| Customization Area | Options | Impact on MOQ | Timeline Impact |

|---|---|---|---|

| Color | Custom pantone matching | Minimal increase (50-100 units) | +3-5 days |

| Material | Firmness adjustments, specialty silicones | Moderate increase (100-200 units) | +7-14 days |

| Surface Texture | Patterns, finishes, embossing | Moderate increase (150-300 units) | +10-21 days |

| Internal Components | Motor power, vibration patterns | Minimal increase (50-100 units) | +5-7 days |

| Packaging | Fully customized boxes and inserts | No impact on product MOQ | +14-21 days |

The most successful customization strategies focus on creating distinctive consumer experiences rather than completely unique appearances. For example, when working with a boutique brand last year, we utilized an existing base design but implemented a custom motor with higher torque and specially programmed vibration patterns. The result was a product that performed differently from competitors while maintaining reasonable MOQs of just 300 units.

Packaging represents another powerful differentiation opportunity that doesn't affect product manufacturing minimums. By creating premium unboxing experiences through custom packaging, brands can establish unique identities even when the core products share some design elements with others on the market.

For brands looking to test markets before larger investments, this approach provides valuable feedback on consumer preferences while maintaining reasonable initial investments. The data gathered from these semi-custom products often informs more comprehensive custom development in subsequent production runs.

What joint development opportunities exist for small-batch vibrator production?

I discovered an untapped approach when a manufacturer mentioned sharing development costs across multiple brands. This collaborative model makes custom designs accessible even for modest order volumes.

Joint development opportunities include participating in manufacturer innovation programs, joining multi-brand development pools, utilizing modular component systems, and sharing seasonal color developments. These collaborative approaches distribute development costs across multiple brands while maintaining brand distinctiveness.

The collaborative development model has emerged as a powerful strategy for brands seeking custom products without bearing the full financial burden of development costs. At VF Pleasure, we've pioneered several joint development programs that enable smaller brands to access custom design without prohibitive investments.

Our innovation sharing program represents one successful collaborative model. In this approach, we develop new base technologies (such as novel motor systems or control mechanisms) and then offer these innovations to multiple brands, each with their own external design modifications. The core development cost is distributed across participating brands, with each maintaining unique market positioning through distinct external features, branding, and marketing approaches.

Modular component systems provide another powerful collaborative opportunity. We've developed interchangeable components that can be mixed and matched to create functionally different products while sharing key parts. For example, our couples toys product line utilizes a common control module that can be paired with different silicone shapes, allowing brands to create unique products while benefiting from shared component development.

Seasonal color development pools have proven particularly effective for smaller brands. Rather than paying for exclusive color development, brands can join development pools for specialty colors, finishes, and effects. Each participating brand commits to purchasing a smaller quantity (typically 200-300 units) in the jointly developed colors, collectively reaching the minimum required for custom color development.

The logistics of these collaborative approaches require careful management of intellectual property considerations. We establish clear agreements regarding which elements are shared and which remain exclusive to each participating brand. These agreements ensure brands maintain their market differentiation while benefiting from the cost efficiencies of shared development.

How are prototyping technologies changing small-batch vibrator manufacturing?

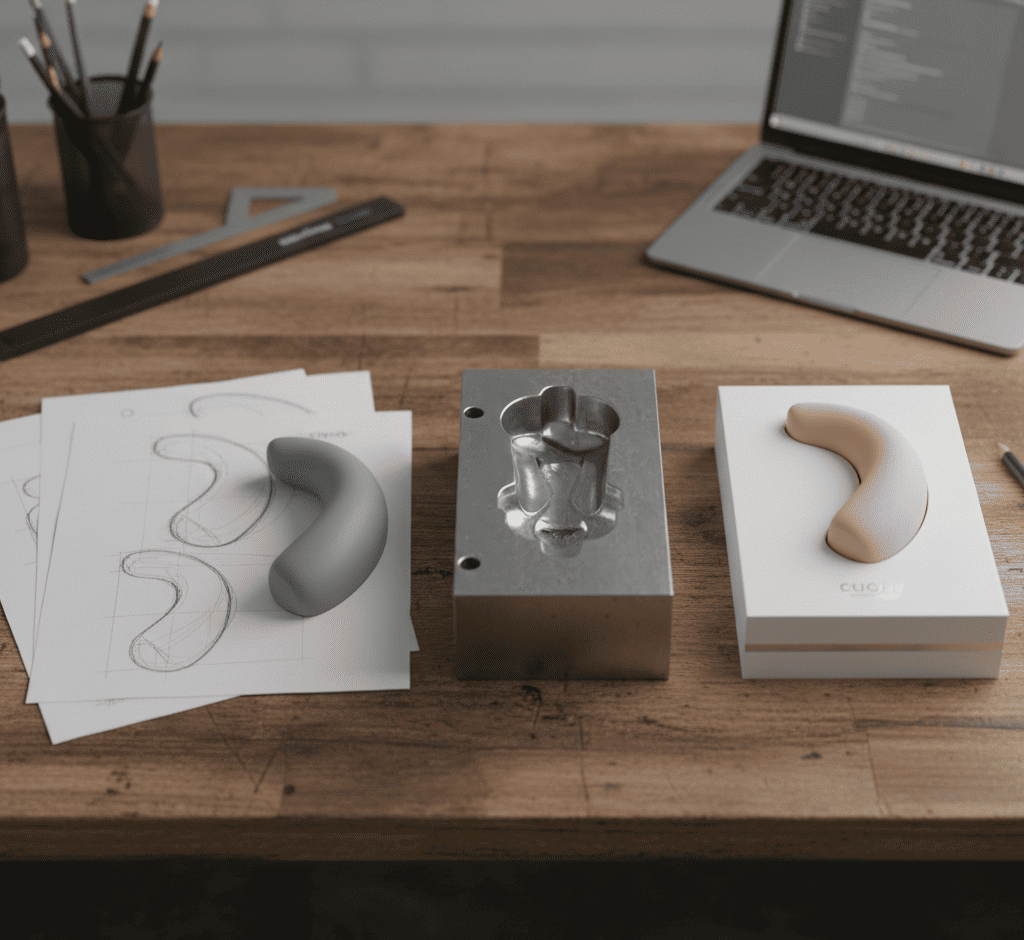

Traditional prototyping required expensive tooling before seeing the final product. New technologies allow us to create functional prototypes without these investments, reducing risks for small batch production.

Advanced prototyping technologies now enable functional vibrator samples using 3D printing with silicone-like materials, rapid CNC machining for components, electronics simulation software, and virtual reality visualization. These technologies reduce development risks and enable test marketing before full production commitments.

The revolution in prototyping technologies has fundamentally changed the custom vibrator development process, particularly for smaller brands seeking to minimize initial investment risks. At VF Pleasure, we've integrated several cutting-edge prototyping technologies into our development pipeline for products including our male adult toys and thrusting sex toys.

3D printing technology has advanced dramatically in recent years, now offering materials that closely simulate the texture and flexibility of production silicone. We utilize multi-material printers that can create prototypes with varying shore hardness zones, mimicking the feel of final products with remarkable accuracy. These printed prototypes allow brands to evaluate ergonomics and form factor before committing to mold development.

For electronic components, we employ rapid PCB prototyping that produces functional circuit boards within days rather than weeks. Combined with pre-programmed microcontrollers, these systems allow brands to test actual vibration patterns, intensity levels, and user interfaces during the prototype phase. This approach identifies potential usability issues before production tooling begins.

Virtual testing environments provide another layer of risk reduction. Using simulation software, we can model how different motor configurations will perform in various silicone densities and shapes. These virtual tests help optimize power consumption, vibration distribution, and heat management before physical prototypes are produced.

Perhaps most significantly, these technologies enable test marketing through limited edition "prototype series" releases. Brands can produce 50-100 units using prototype-stage manufacturing methods, sell them as exclusive limited editions, and gather crucial market feedback. While these units cost more to produce than mass manufacturing, they provide invaluable data that reduces risk for subsequent production runs.

The financial impact of these prototyping approaches is substantial. Traditional development might require $10,000-20,000 investment before seeing functional samples. Our integrated prototyping approach delivers testable samples for $2,000-5,000, representing a 75-80% reduction in initial development risk.

How important are manufacturer relationships in securing low MOQ arrangements?

When I first approached factories as an unknown brand, most ignored my inquiries. Building personal relationships completely changed the equation, opening doors to flexible arrangements not offered to outsiders.

Strong manufacturer relationships are critical for low MOQ arrangements, developed through factory visits, consistent communication, transparent business plans, and progressive scaling commitments. These relationships provide flexibility on minimums, priority production scheduling, and access to manufacturer innovation programs.

The relationship factor in securing favorable manufacturing terms cannot be overstated, particularly in China's adult toy manufacturing sector. At VF Pleasure, we've observed that the strongest partnerships develop through consistent engagement rather than transactional approaches.

Factory visits represent an essential investment for brands serious about developing custom products with favorable terms. These in-person visits demonstrate commitment and allow manufacturers to assess the brand's professionalism and growth potential. During these visits, manufacturers often reveal flexibility options not advertised on their websites or initial communications.

Communication consistency builds trust incrementally. Regular updates about business development, even when not placing orders, help manufacturers view brands as long-term partners rather than one-time customers. This ongoing dialogue creates opportunities for manufacturers to offer solutions when capacity becomes available or suggest alternative approaches to achieve brand goals.

Transparency about business plans significantly impacts manufacturer flexibility. When brands share their growth strategies, market positioning, and sales projections, manufacturers can make informed decisions about accepting lower initial MOQs with the understanding that volumes will increase over time. This transparency works both ways - manufacturers who openly discuss their production constraints and capabilities establish more realistic expectations.

Progressive scaling commitments provide a structured approach to balancing manufacturer needs with brand limitations. For example, our typical arrangement with new brands might include:

- Initial order: 300 units with semi-custom features

- Second order: 500 units with additional customization options

- Third order: 1,000+ units with fully custom development potential

This scaling approach gives manufacturers confidence in the partnership's growth trajectory while allowing brands to build market presence gradually. For our private label sex toys program, we've found this progressive approach creates successful long-term relationships that benefit both parties.

The practical benefits of strong relationships extend beyond MOQ flexibility to include production priority during busy seasons, access to manufacturer innovation programs, and more favorable payment terms than offered to new clients.

Conclusion

Launching custom vibrators with low MOQs in China requires strategic approaches: leveraging existing molds, exploring joint development, utilizing advanced prototyping, and building strong manufacturer relationships. These strategies make customized adult products accessible even for brands with limited initial production volumes.