Disappointed by weak vibrations that promise the world but deliver nothing? Most clitoral stimulators use cheap motors and poor design that create buzzy, numbing sensations. Understanding the engineering behind truly powerful devices prevents costly mistakes.

Powerful clitoral stimulators combine high-torque motors producing 8,000+ RPM, premium materials, and acoustic resonance engineering. The most intense devices use deep, rumbly vibrations rather than surface-level buzz, requiring specialized manufacturing capabilities that only advanced factories possess.

After 15 years developing clitoral stimulator exporter products at VF Pleasure, I've learned that motor technology separates mediocre toys from mind-blowing experiences. Most manufacturers use standard bullet motors that create surface vibrations. Our breakthrough came when we invested in custom motor development at our Shenzhen R&D facility. The difference between cheap and premium motors is like comparing a smartphone speaker to a concert sound system.

- 1 What Motor Technologies Actually Create Powerful Sensations?

- 2 How Do Materials and Design Amplify Motor Power?

- 3 What Role Does Ergonomic Design Play in Perceived Intensity?

- 4 How Do Advanced Features Enhance Stimulation Intensity?

- 5 What Manufacturing Standards Ensure Consistent Power Delivery?

- 6 Conclusion

What Motor Technologies Actually Create Powerful Sensations?

Confused by technical specifications that don't translate to real performance? Motor RPM numbers often mislead because frequency matters less than torque and vibration pattern. Understanding motor engineering helps identify truly powerful devices.

High-performance clitoral stimulators use brushless DC motors with rare earth magnets, custom-wound coils, and precision-balanced rotors. These motors produce 40-60% more torque than standard designs while reducing noise and extending battery life through superior efficiency.

Motor engineering determines everything about a stimulator's performance, and most buyers have no idea what to look for. At our adult toys factory, we developed custom motors after realizing commercial options couldn't deliver the intensity our clients demanded. Standard bullet motors use brushed designs that create electrical noise, generate heat, and lose power over time. Our brushless motors use neodymium magnets and precision-wound copper coils that deliver consistent power throughout battery discharge. The secret is torque-to-weight ratio - powerful motors must generate substantial force without making devices too heavy or bulky. We achieve this through advanced magnetic field optimization and lightweight titanium components. Motor placement within the device affects intensity dramatically. Motors positioned closer to the stimulation point transfer more energy, while internal mounting systems prevent vibration loss through the housing. For our custom vibrators, we design entire products around motor performance rather than fitting motors into pre-designed shells. Frequency response matters enormously - the human body responds differently to various vibration frequencies, with 20-150 Hz providing optimal clitoral stimulation. Our motors can produce pure frequencies or complex waveforms that create unique sensations impossible with standard designs. Quality control includes testing every motor under load conditions that simulate extended use. When procurement professionals like Felle evaluate our wholesale adult toys, motor specifications often determine selection because performance directly impacts customer satisfaction and return rates.

| Motor Type | Torque (mN·m) | Noise Level (dB) | Battery Life | Cost Premium | Performance Rating |

|---|---|---|---|---|---|

| Standard Brush | 15-25 | 45-55 | 2-3 hours | Baseline | 6/10 |

| High-Grade Brush | 30-45 | 40-50 | 3-4 hours | +20% | 7/10 |

| Brushless DC | 50-70 | 35-45 | 4-6 hours | +60% | 9/10 |

| Custom Brushless | 70-100 | 30-40 | 6-8 hours | +120% | 10/10 |

| Linear Actuator | 80-120 | 25-35 | 5-7 hours | +150% | 10/10 |

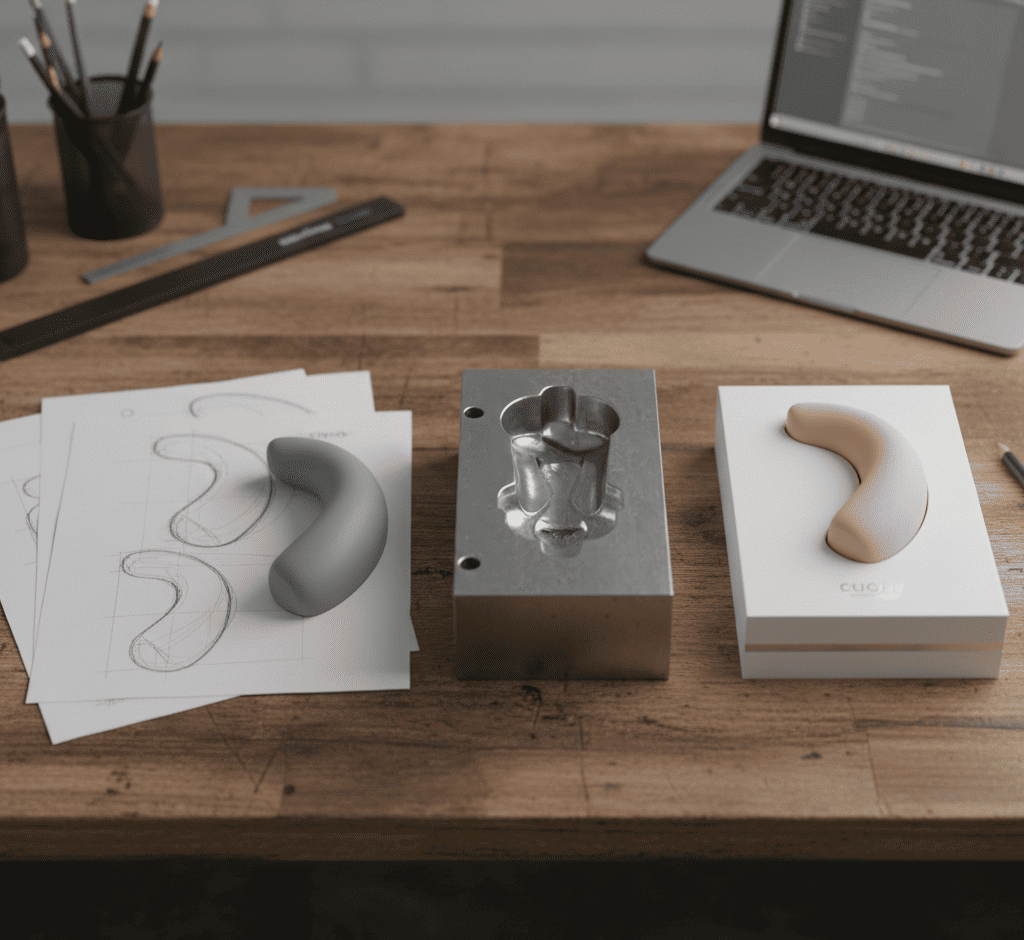

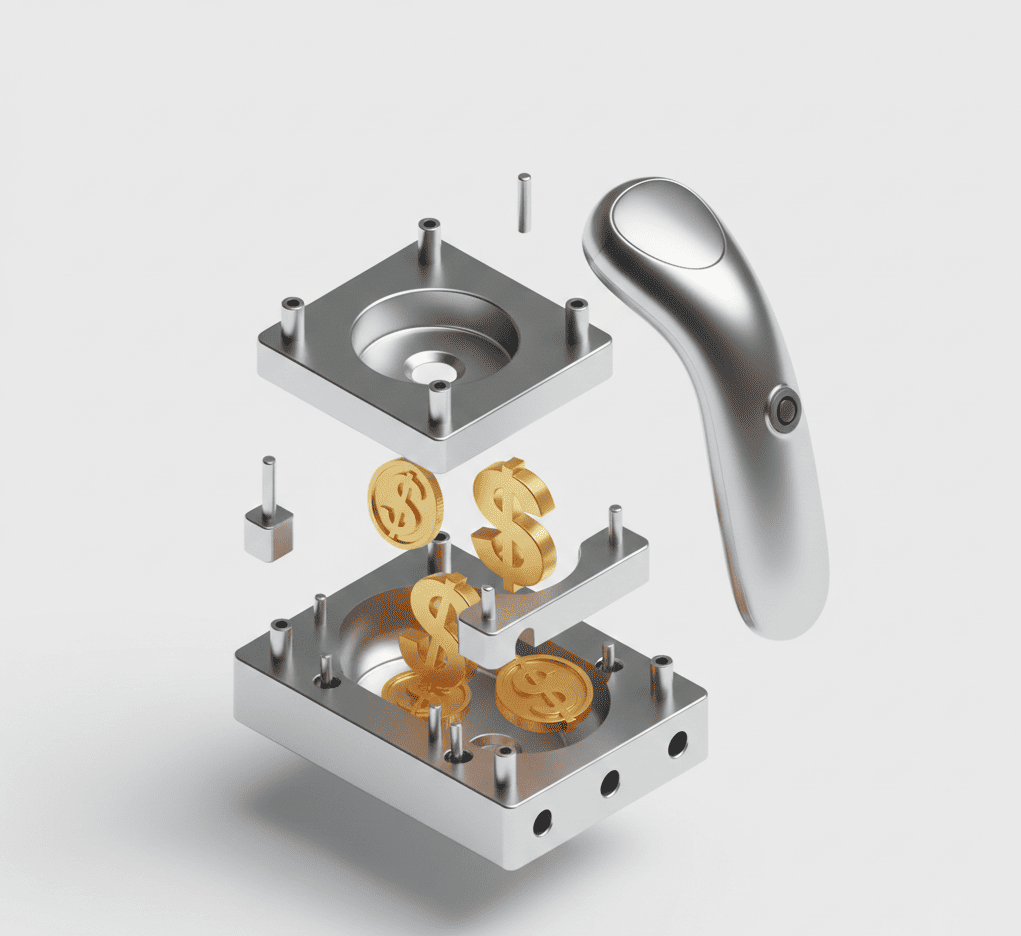

How Do Materials and Design Amplify Motor Power?

Wondering why identical motors feel different in various products? Material properties and internal design dramatically affect how motor power translates to user sensation. Smart engineering can amplify weak motors or waste powerful ones.

Premium materials like medical-grade platinum silicone and acoustic resonance chambers can increase perceived intensity by 40-80%. Internal design elements including weighted tips, resonance cavities, and vibration focusing systems transform raw motor power into targeted sensations.

Material science revolutionized our approach to powerful stimulators when we discovered how different silicones transmit vibrations. Standard TPE and basic silicones absorb and dampen motor energy, while our customized platinum silicone formulations enhance and focus vibrations. The durometer (firmness) affects transmission - softer materials feel gentler but waste power, while firmer materials transmit more energy but may cause discomfort. We developed gradient durometer designs where the contact surface remains soft while internal structures stay firm for optimal power transmission. Resonance chamber engineering multiplies motor effectiveness by creating acoustic amplification within the device body. These chambers work like speaker enclosures, focusing and intensifying vibrations at specific frequencies. Our female sex toys incorporate tuned resonance systems that increase perceived power while reducing battery drain. Weight distribution affects sensation significantly - strategic placement of dense materials like steel or tungsten tips focuses vibration energy precisely where needed. For air pulse technologies, chamber design and membrane materials determine suction intensity and pattern accuracy. Our sucking vibrator exporter products use proprietary membrane compounds that maintain elasticity while delivering precise pressure variations. Surface texturing interacts with vibrations to create unique sensations impossible with smooth surfaces. Micro-textured contact points amplify gentle vibrations while maintaining comfort during extended use. The key is matching material properties to intended sensations rather than using generic formulations. When developing OEM adult toys manufacturer products, we select materials based on specific performance targets and user feedback rather than cost considerations alone.

What Role Does Ergonomic Design Play in Perceived Intensity?

Surprised how device shape affects intensity more than motor power? Poor ergonomics waste the most powerful motors while smart design makes modest motors feel incredible. Understanding anatomical compatibility maximizes any device's potential.

Ergonomic design matching female anatomy can increase effective stimulation by 200-300% compared to generic shapes. Key factors include contact angle, pressure distribution, grip positioning, and anatomical accommodation for different body types and sensitivity levels.

Ergonomic design became our obsession after realizing powerful motors meant nothing without proper contact and positioning. At our R&D center, we studied female anatomy extensively to understand how device shape affects sensation transmission. The contact angle between stimulator and clitoris determines how much motor energy reaches nerve endings. Generic bullet shapes make minimal contact, while our anatomically optimized designs maximize surface contact for superior energy transfer. Pressure distribution prevents numbness and discomfort that plague poorly designed devices. Our custom sex toys spread stimulation across optimal zones rather than concentrating power in tiny points that cause pain. Grip design affects user control and comfort during extended sessions. Devices that slip or require uncomfortable hand positions reduce effectiveness regardless of motor power. We design grips that feel natural and secure while allowing precise positioning adjustments. Internal weight distribution affects handling and reduces hand fatigue that interrupts sessions. For personalized sex toys, we customize shapes based on individual anatomy and preferences because one size definitely doesn't fit all. Clitoral size, sensitivity, surrounding tissue, and preferred stimulation angles vary dramatically between users. Our ergonomic studies revealed that device effectiveness depends more on anatomical compatibility than raw power specifications. Size scaling affects everything - larger devices provide broader stimulation while smaller ones offer pinpoint precision. The optimal size depends on individual anatomy and stimulation preferences. For couples use, ergonomics must accommodate partner interaction without compromising solo functionality. Our couples toys designs consider hands-free operation and partner accessibility. Quality ergonomic design requires expensive research, custom tooling, and multiple prototype iterations, but the performance improvements justify the investment through superior user satisfaction.

How Do Advanced Features Enhance Stimulation Intensity?

Curious about features beyond basic vibration patterns? Modern clitoral stimulators integrate smart technology, biometric feedback, and adaptive systems that personalize intensity automatically. These innovations create experiences impossible with traditional devices.

Advanced features include biometric sensors providing real-time intensity adjustment, smartphone app connectivity with infinite customization, heating elements for enhanced blood flow, and AI learning systems that adapt to individual preferences over extended use periods.

Technology integration transformed clitoral stimulators from simple vibrators into sophisticated pleasure devices rivaling consumer electronics. Our latest vibrator factory productions incorporate sensors that monitor skin temperature, moisture levels, and pressure to automatically adjust intensity for optimal stimulation. These biometric systems prevent numbing while maintaining peak sensation throughout sessions. Smartphone connectivity allows infinite pattern customization, session tracking, and remote partner control that creates entirely new experience categories. Our app development team works alongside hardware engineers to ensure seamless integration between physical devices and digital interfaces. Heating elements enhance stimulation by improving blood flow to targeted areas, increasing sensitivity and responsiveness to vibrations. The heating systems use medical-grade warming technology similar to therapeutic devices. AI learning algorithms analyze usage patterns to suggest optimal settings and automatically adjust programs based on individual preferences. These systems learn from biometric feedback and user input to create increasingly personalized experiences. For long-distance relationships, our teledildonics integration enables real-time interaction through internet connectivity and haptic feedback systems. Voice control eliminates the need for manual adjustments during peak moments, while gesture recognition provides intuitive operation. Advanced battery management systems provide consistent power output throughout discharge cycles, preventing the intensity reduction common in basic devices. Our manufacturer direct vibrators include fast-charging capabilities and extended runtime for uninterrupted sessions. Quality advanced features require partnerships with technology companies, software development capabilities, and regulatory compliance for wireless communications. The investment is substantial, but premium pricing and customer loyalty justify the development costs.

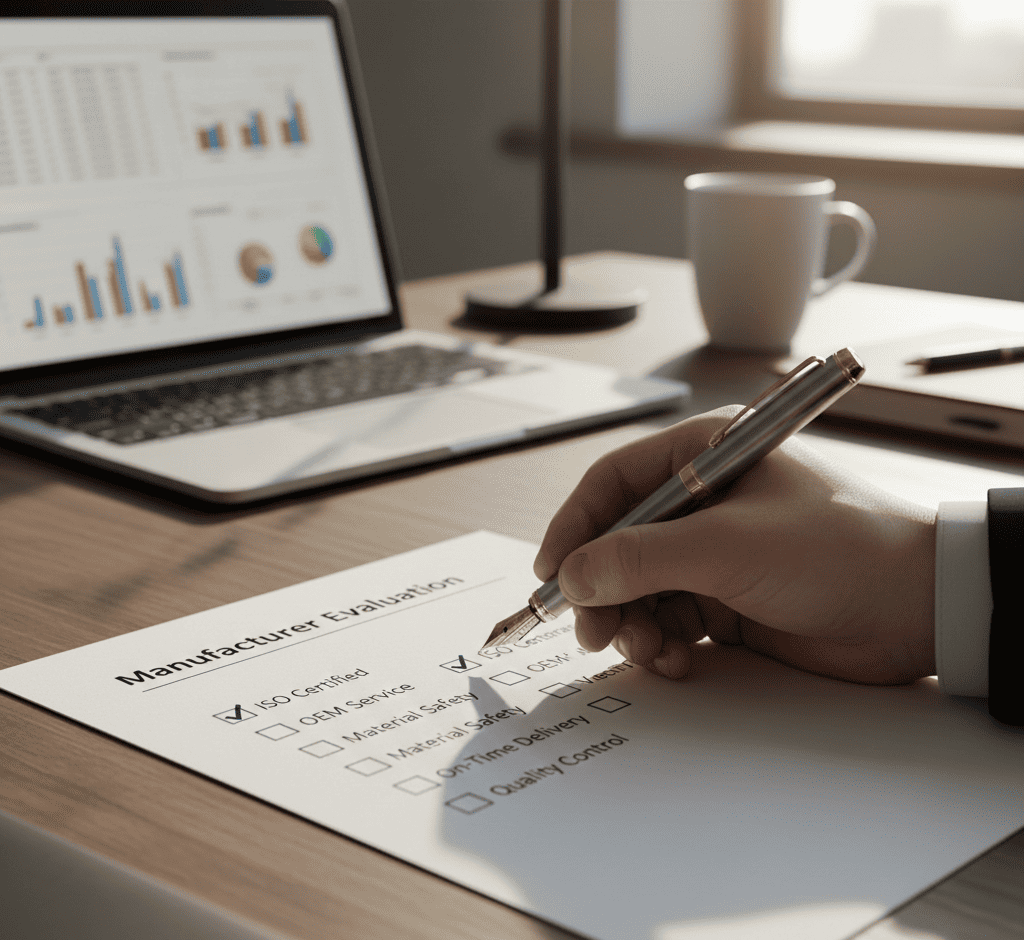

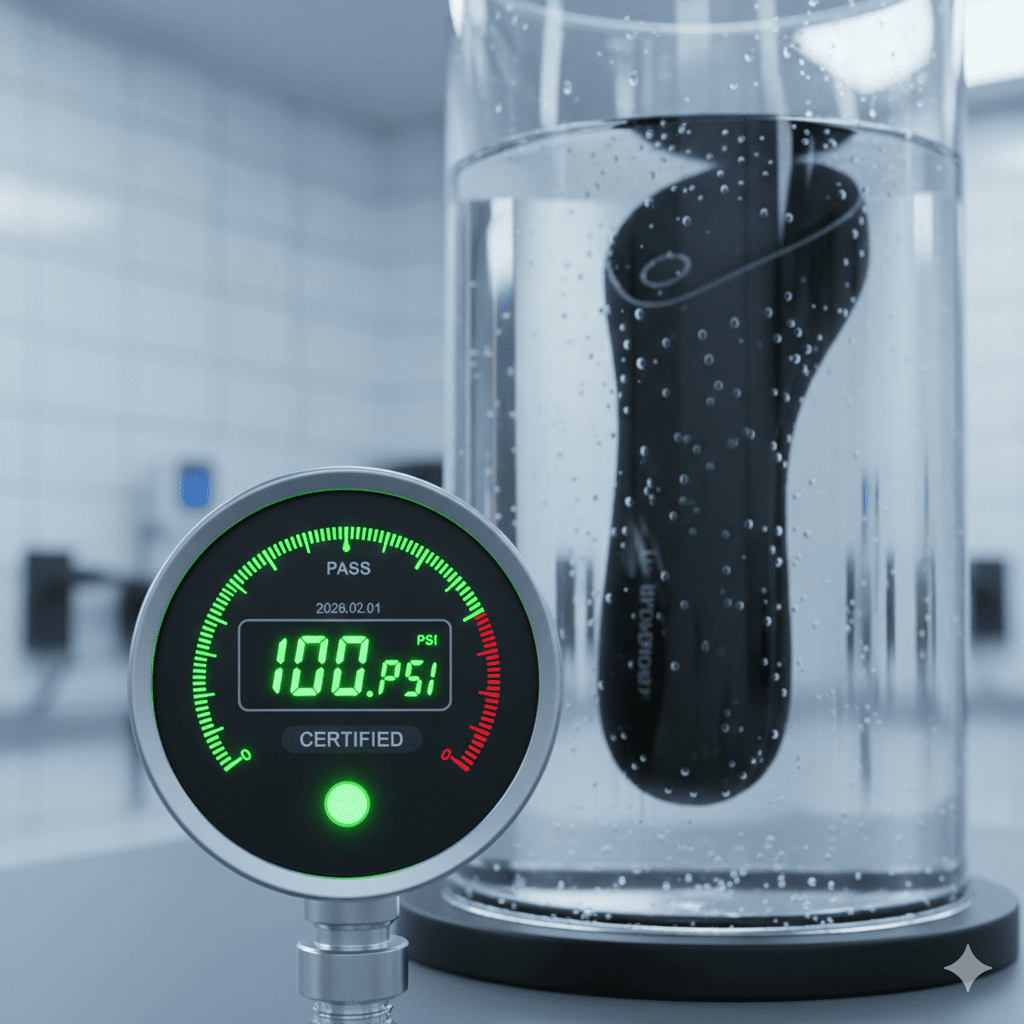

What Manufacturing Standards Ensure Consistent Power Delivery?

Concerned about quality control in powerful devices? Manufacturing variations can create dramatic performance differences between identical models. Understanding production standards helps identify reliable suppliers and consistent products.

Premium manufacturing requires ISO 13485 medical device standards, individual motor testing, calibrated assembly procedures, and final performance validation. Quality facilities achieve 99%+ consistency in power output with less than 5% variation between units.

Manufacturing consistency separates professional operations from amateur producers who create unreliable products that damage brand reputations. At our Dongguan facilities, every motor undergoes individual testing for torque, noise, and power consumption before assembly. We maintain calibrated test equipment traceable to international standards and document every measurement for quality analysis. Assembly procedures require trained technicians who understand how component variations affect final performance. Torque settings for screws, positioning tolerances for internal components, and material application procedures all impact device effectiveness. Our sex toys factory uses statistical process control to identify trends before they affect product quality. Final performance testing validates every device meets specification requirements for power output, battery life, noise levels, and safety parameters. We simulate months of use through accelerated testing protocols that reveal potential reliability issues. For bulk adult toys production, consistency becomes even more critical because variations create customer complaints and returns. Our quality management system tracks performance data from production through field use to identify improvement opportunities. Supplier qualification ensures component consistency from motors through materials and electronics. We maintain approved vendor lists with performance requirements and audit schedules. Environmental controls in production areas prevent contamination and ensure consistent curing of silicone materials. Temperature and humidity variations can affect material properties and assembly procedures. When Felle evaluates our adult toy suppliers capabilities, manufacturing standards often determine selection because consistency affects customer satisfaction ratings and return rates. Professional operations invest in quality systems that cost more initially but reduce long-term warranty costs and maintain brand reputation.

Conclusion

Powerful clitoral stimulators require advanced motor technology, premium materials, and precise manufacturing to deliver intense, consistent sensations. Understanding these engineering principles helps identify truly exceptional products worth premium pricing.