Many retailers struggle to find reliable rose vibrator suppliers with reasonable minimum orders. Standard wholesalers offer generic products with high minimums, leaving businesses unable to differentiate themselves or test new products.

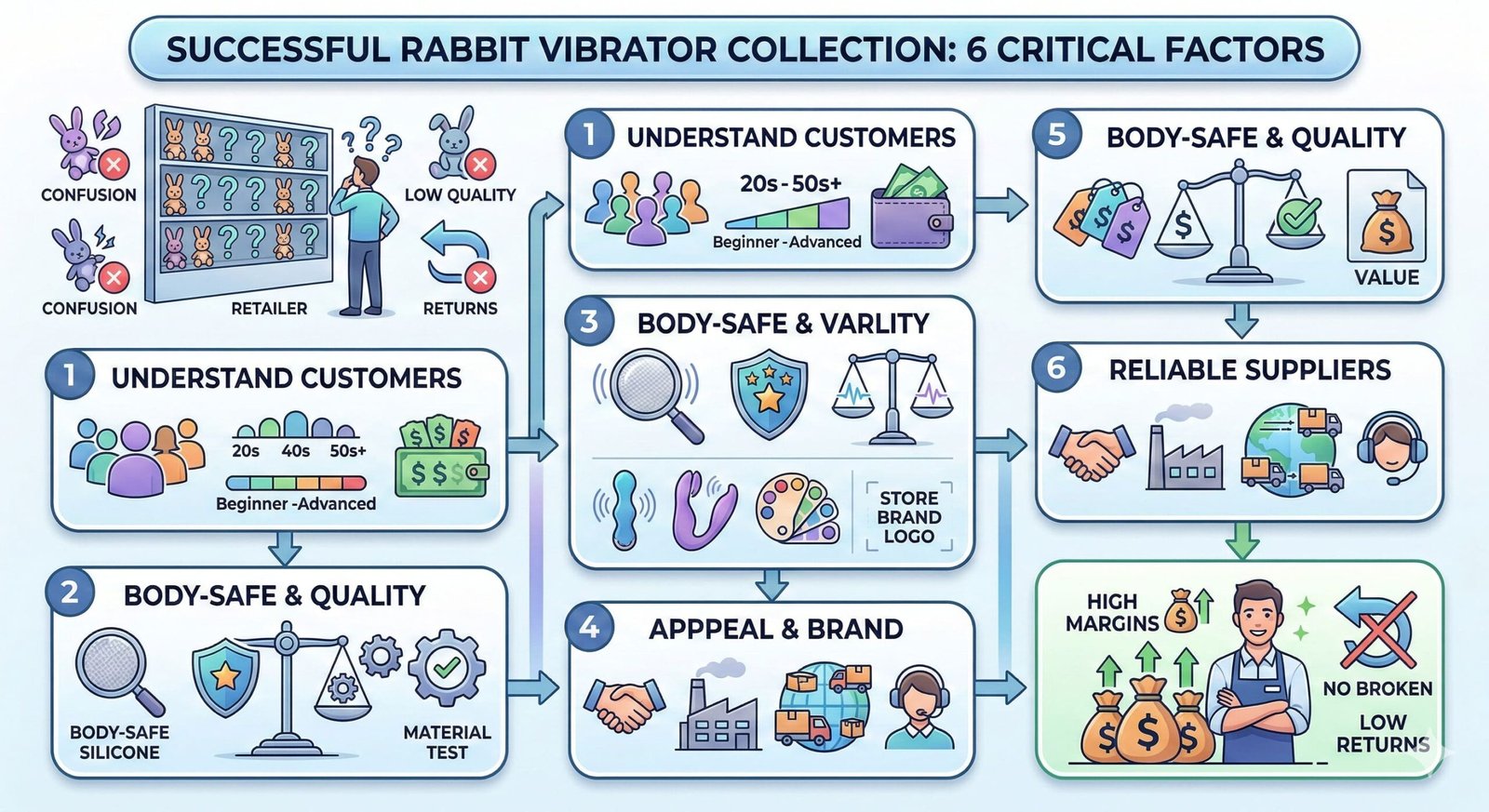

When sourcing rose vibrators wholesale, prioritize manufacturers offering customization options, quality materials (medical-grade silicone), reliable motors, comprehensive quality control, and flexible MOQs (200-500 units). These factors ensure competitive products that meet consumer expectations.

In my years working with adult product retailers across the US, I've seen countless businesses struggle with rose vibrator sourcing. The difference between success and failure often comes down to finding the right manufacturing partner who understands your specific needs. Let me share what I've learned about making these critical sourcing decisions.

- 1 Why has the rose vibrator become such a popular product category?

- 2 What quality factors should you evaluate when sourcing wholesale rose vibrators?

- 3 How can customization differentiate your rose vibrator offerings?

- 4 Why do minimum order quantities matter for rose vibrator retailers?

- 5 How can you navigate pricing and negotiation when sourcing rose vibrators?

- 6 How do you evaluate potential rose vibrator manufacturers beyond price and MOQ?

- 7 Conclusion

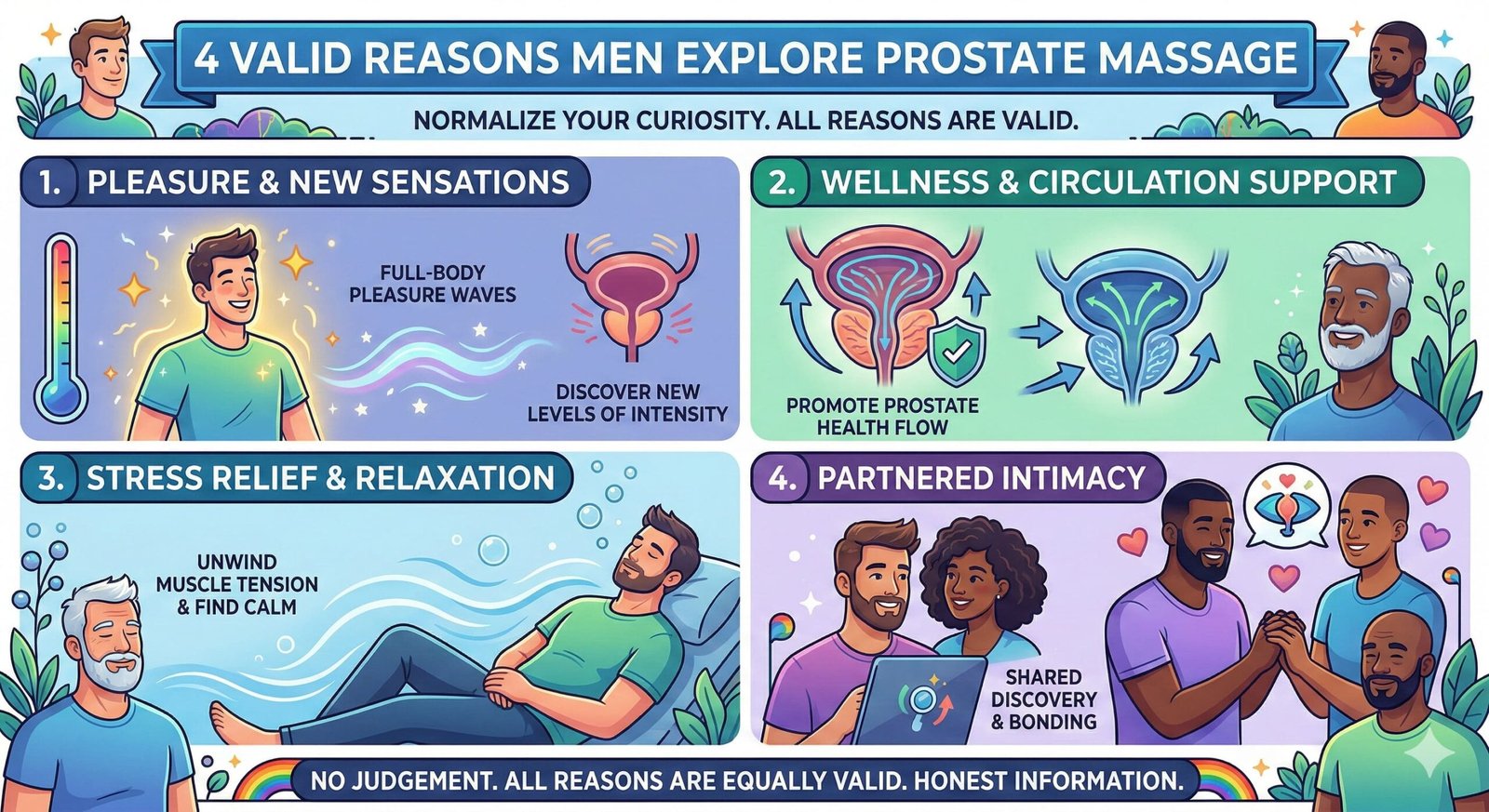

Why has the rose vibrator become such a popular product category?

Many retailers underestimate the staying power of rose vibrators, seeing them as just another trend. I initially made this mistake myself, only to watch competitors capture significant market share.

The rose vibrator category has gained popularity due to its distinctive flower-shaped design that appeals to first-time buyers, powerful suction technology providing unique stimulation, discreet appearance that reduces stigma, social media virality, and versatile functionality. These factors have transformed it from trend to staple product.

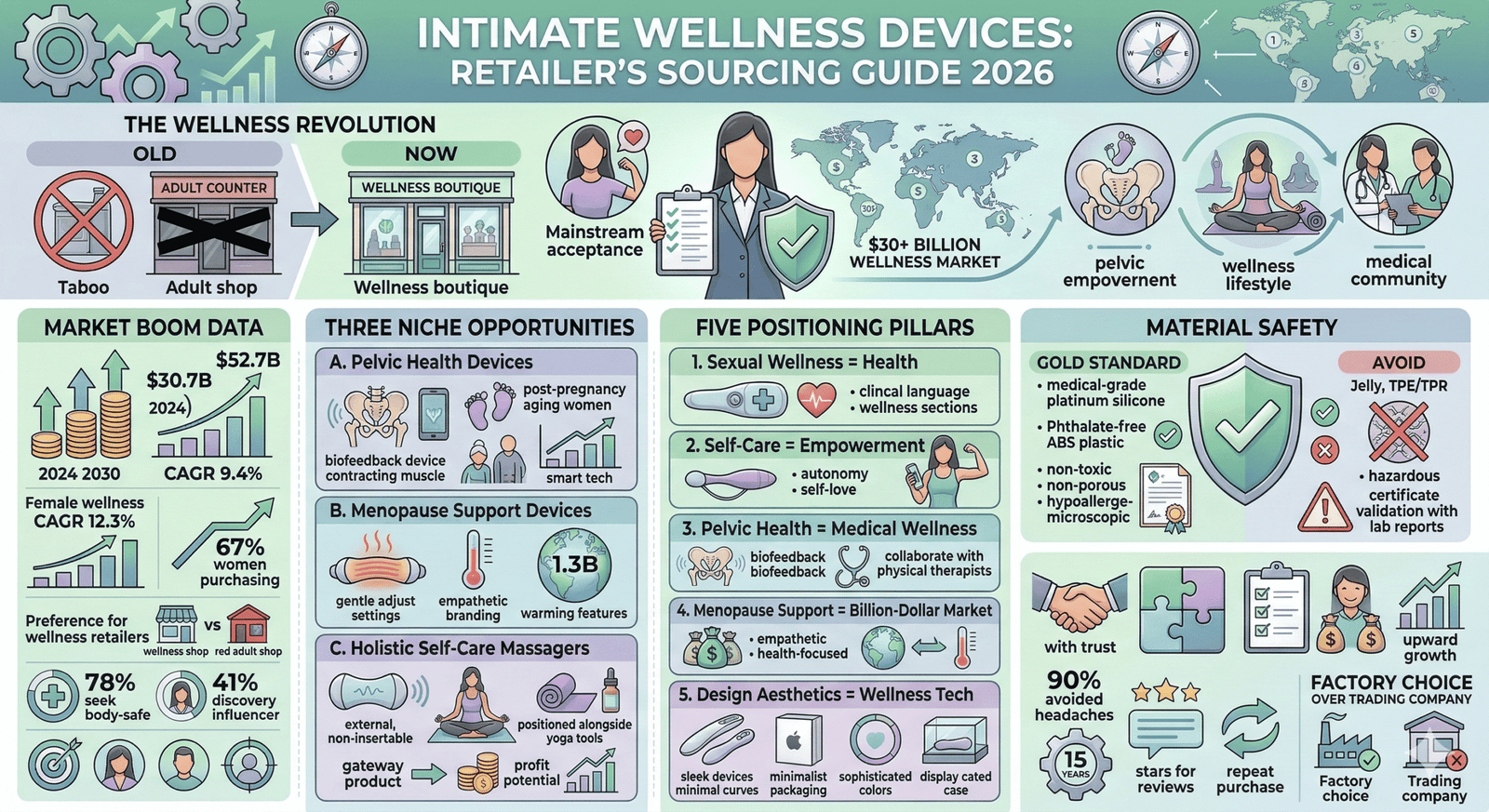

The meteoric rise of rose vibrators represents one of the most significant shifts in the adult toy market in recent years. At VF Pleasure, we've tracked this category's evolution from novelty to essential product through both market research and sales performance across our client networks.

The distinctive flower-shaped design marked a radical departure from traditional vibrator aesthetics, which often prioritized anatomical realism or clinical minimalism. This shift resonated powerfully with consumers who found the floral appearance both aesthetically pleasing and emotionally accessible. Our customer feedback surveys show that approximately 32% of rose vibrator purchasers identify as first-time adult toy buyers, significantly higher than the 18% average across other product categories.

The technological innovation behind these products further explains their sustained popularity. The suction and pulsation technology combines precision engineering with ergonomic design to deliver stimulation patterns that many consumers report as uniquely satisfying. This technological differentiation created genuine word-of-mouth marketing that transcended typical product cycles.

The discreet nature of rose vibrators has broken down significant barriers to purchase. The plausible deniability offered by their floral appearance means they can remain visible in personal spaces without creating discomfort, unlike more anatomically explicit products. This characteristic has expanded the potential customer base dramatically, particularly in more conservative markets where traditional adult toys face greater stigma.

Social media's role in popularizing rose vibrators cannot be overstated. The combination of aesthetic appeal and genuine consumer enthusiasm created organic viral moments across platforms from TikTok to Instagram. Unlike many adult products that face advertising restrictions, rose vibrators' discreet design allowed for greater visibility in mainstream channels, further accelerating their market penetration.

For retailers, understanding these underlying factors is crucial to successful merchandising. The rose vibrator isn't merely a trendy silhouette but represents a fundamental shift in how consumers approach personal pleasure products – prioritizing discretion, aesthetics, and technological innovation in equal measure.

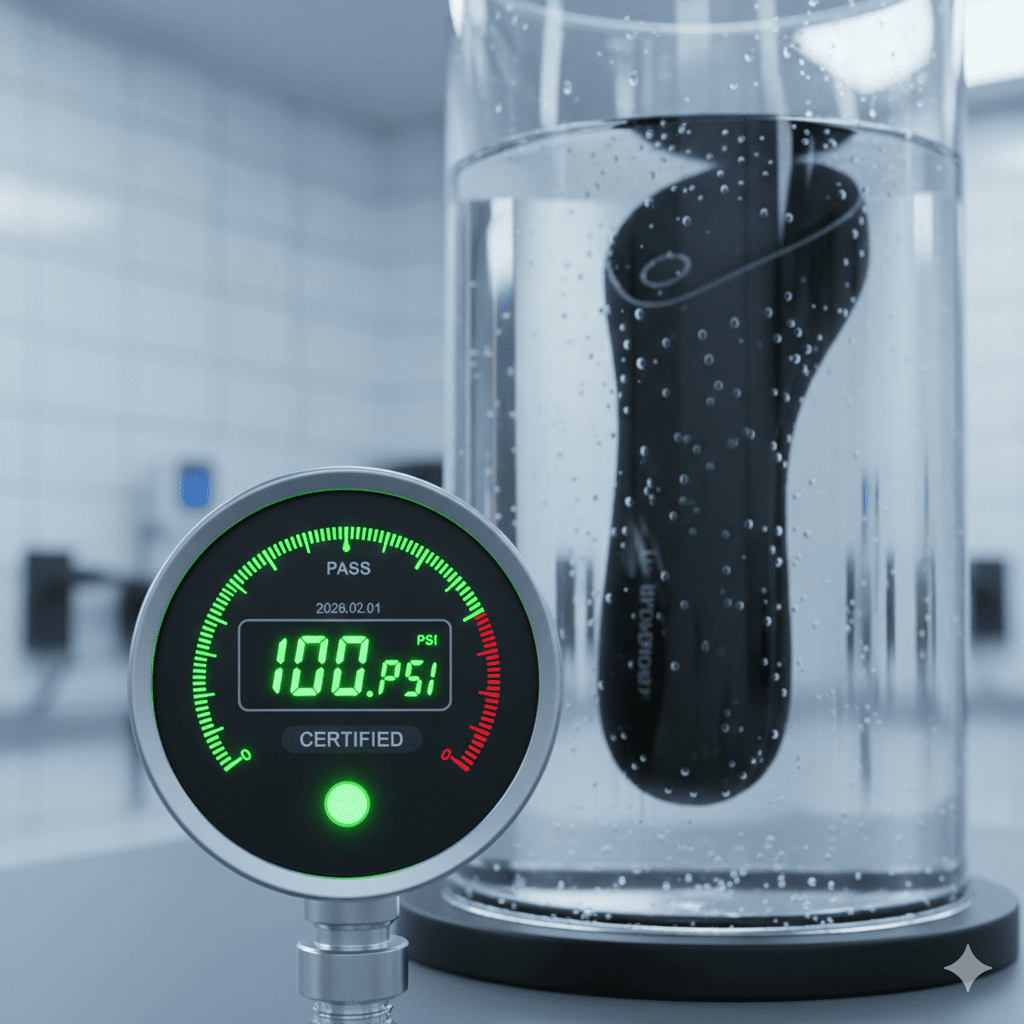

What quality factors should you evaluate when sourcing wholesale rose vibrators?

When I first began sourcing rose vibrators, I focused primarily on price. This approach backfired when customer returns increased due to poor quality products that damaged our reputation.

When evaluating wholesale rose vibrators, assess: silicone quality (medical-grade vs TPE), motor performance (runtime and noise levels), waterproofing integrity, battery specifications (mAh capacity and charging cycles), and comprehensive testing documentation. Quality factors directly impact customer satisfaction, returns, and reputation.

The quality assessment of wholesale rose vibrators requires a systematic approach focusing on several critical components that directly impact consumer satisfaction and product longevity. At VF Pleasure, our quality control process for vibrator products emphasizes both material and performance factors.

Material composition represents the foundational quality indicator for rose vibrators. Medical-grade silicone offers substantial advantages over thermoplastic elastomers (TPE) including hypoallergenic properties, longer lifespan, and superior heat resistance. However, material quality assessment requires more than supplier claims. We implement specific testing protocols including:

Material Quality Testing Procedures

| Test Type | Parameters Measured | Acceptable Results |

|---|---|---|

| Shore Durometer Test | Material firmness | 30-45A for external contact areas |

| Heat Resistance Test | Material integrity after exposure | No deformation at 150°C |

| Chemical Stability | Reaction with lubricants | No visible degradation after 24hr exposure |

| Cytotoxicity Testing | Biocompatibility | ISO 10993-5 compliance |

Motor quality directly determines user experience through performance consistency and product longevity. The evaluation process should include operational testing under various conditions, with particular attention to:

- Continuous runtime performance (minimum 120 minutes at highest intensity)

- Noise level measurement (<50db at 30cm distance)

- Heat generation during extended operation

- IP rating verification for waterproofing claims

Battery specifications significantly impact both user experience and product lifespan. Many wholesale suppliers provide inadequate information regarding battery components. Our evaluation prioritizes lithium polymer batteries with minimum 500mAh capacity for standard rose vibrators, with verification of:

- Charge cycle specifications (minimum 300 full cycles)

- Charging circuit protection features

- Discharge rate consistency

Controller and electronic components quality often receives insufficient attention during sourcing decisions. These components determine the reliability of vibration patterns, intensity control, and overall product durability. Our testing protocol includes thermal imaging during operation to identify potential failure points and standard drop testing to verify component mounting security.

For our female sex toys including rose vibrators, we maintain comprehensive testing documentation that tracks performance across production batches. This documentation should be available from quality-focused manufacturers and should include:

- Material certifications from recognized testing authorities

- Production sample test results including motor performance metrics

- Batch testing reports showing consistency across production runs

The direct correlation between quality factors and business success cannot be overstated. Higher quality products not only reduce return rates but significantly increase reorder probability and positive reviews. In our experience, investing an additional $3-5 per unit in quality components typically reduces return rates by 8-12%, creating substantial long-term revenue benefits despite the higher initial cost.

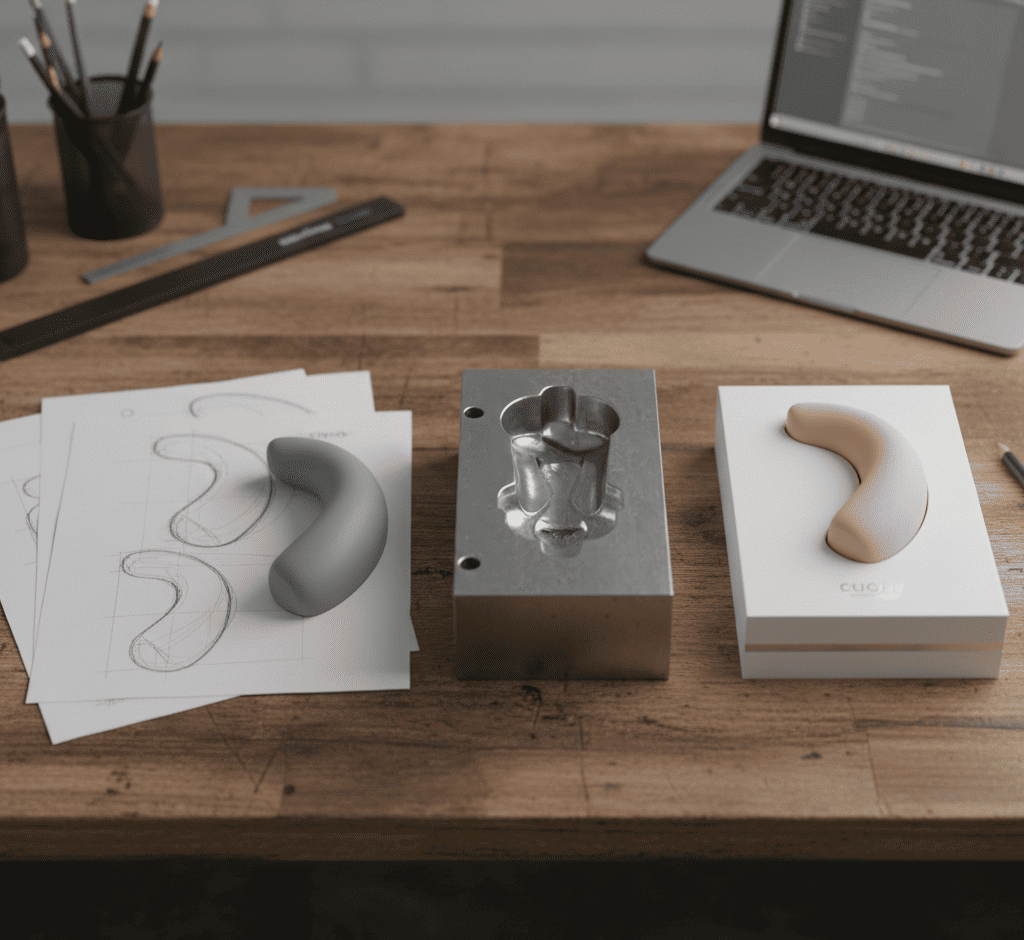

How can customization differentiate your rose vibrator offerings?

Standard wholesale channels offered me identical products to my competitors. Custom features allowed my retail chain to develop unique selling propositions that competitors couldn't match.

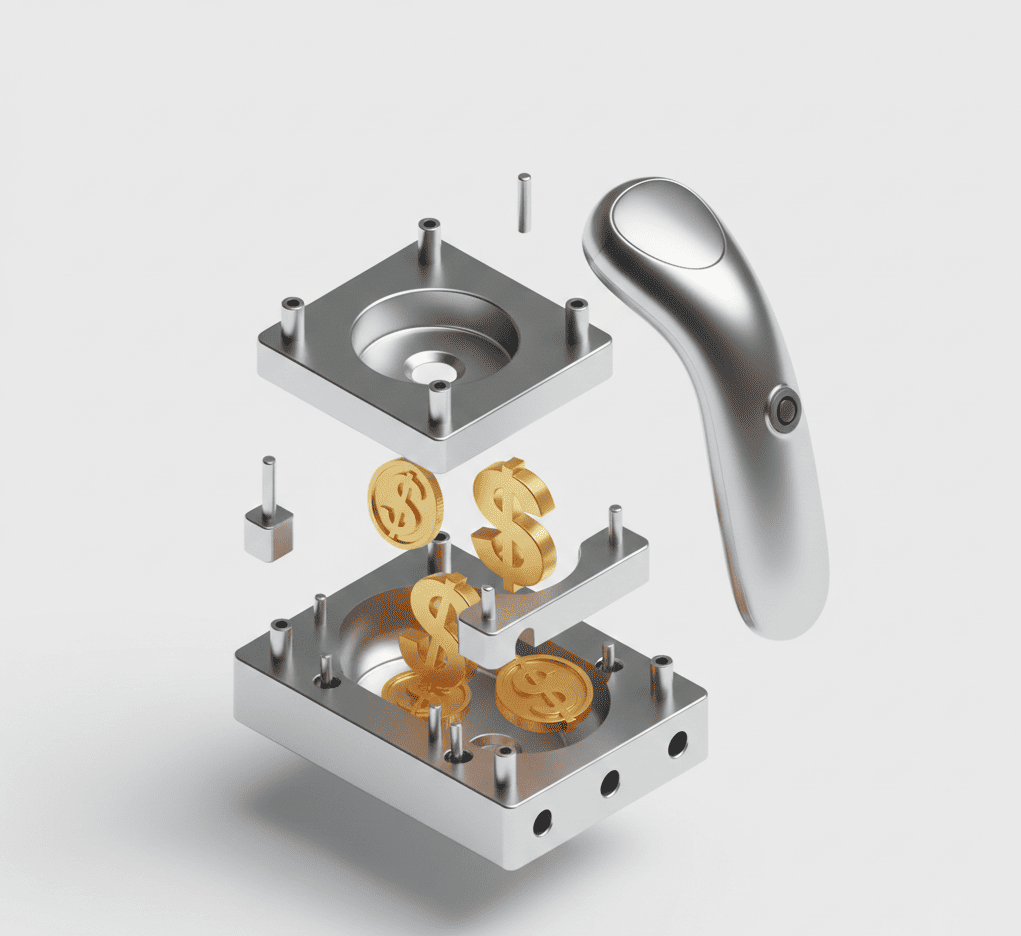

Customization options for rose vibrators include unique vibration patterns, custom colors and finishes, proprietary feature development, branded packaging and accessories, and specialized marketing materials. These customization options create differentiation in competitive markets and support higher margin potential.

The strategic customization of rose vibrators creates substantial competitive advantages in an increasingly crowded market segment. At VF Pleasure, we've developed customization pathways that balance distinctiveness with manufacturing efficiency.

Vibration pattern customization offers perhaps the most compelling functional differentiation opportunity. Standard wholesale products typically feature 8-10 generic patterns, while our customization program enables retailers to develop signature vibration sequences tailored to their customer preferences. This process involves:

- Identifying baseline customer preferences through market research

- Developing 3-5 proprietary patterns with varied intensity progressions

- Programming and testing pattern effectiveness with sample groups

- Implementing final patterns in production units

The technical implementation requires minimal tooling changes while creating a significantly differentiated user experience. Retailers who implement custom vibration patterns report 12-15% higher customer satisfaction ratings compared to standard programming.

Color and finish customization extends beyond simple color matching to include specialized surface treatments. Our advanced manufacturing capabilities for thrusting sex toys and rose vibrators include:

- Multi-zone silicone coloration with up to three distinct color sections

- Specialty finishes including metallic fleck integration and pearlescent effects

- Custom texturing including micro-patterns and embossed branding elements

- Two-tone color transitions achieved through advanced molding techniques

These visual customizations create immediate shelf differentiation while reinforcing brand identity. Particularly effective are color palettes aligned with broader brand aesthetics that create recognition across product lines.

Feature development represents the highest level of customization, involving adaptation of base mechanisms to create truly unique products. For example, our engineering team recently developed a modified rose vibrator featuring enhanced ergonomics for customers with dexterity limitations – a unique offering that addressed an underserved market segment. Feature development typically follows a structured process:

- Concept development based on customer feedback or market gaps

- Engineering feasibility assessment

- Prototype development and testing

- Small production run (typically 300-500 units)

- Market feedback collection and feature refinement

- Full production implementation

Packaging customization offers immediate differentiation opportunities with minimal technical complexity. Beyond simple logo placement, effective packaging customization includes:

- Custom structural designs that enhance unboxing experience

- Integrated educational materials specific to product features

- QR codes linking to proprietary content including tutorials

- Retailer-specific warranty and support information

For new brands entering the market, our private label sex toys program combines these customization elements into comprehensive brand development packages that create cohesive product identities from product to packaging to marketing materials.

The business impact of these customization strategies extends beyond simple product differentiation. Customized rose vibrators typically command 15-30% higher retail prices than generic alternatives, with corresponding margin improvements. Additionally, custom products significantly reduce direct price competition with identical products in the market, allowing retailers to maintain healthy margins even in competitive environments.

Why do minimum order quantities matter for rose vibrator retailers?

Early in my career, I committed to massive inventory based on a supplier's minimum requirements. This left us with unsold stock when customer preferences shifted, creating serious cash flow problems.

MOQs matter because they affect inventory risk exposure, new product testing ability, product range diversity, capital allocation efficiency, and response time to market trends. Flexible MOQs (200-500 units) allow retailers to test products before full commitments, optimize inventory management, and maintain product freshness.

The strategic importance of minimum order quantities cannot be overstated in the adult product retail sector. At VF Pleasure, we've observed the direct relationship between MOQ flexibility and business sustainability across our client network.

Inventory risk exposure represents the most immediate impact of high minimum order requirements. Standard industry MOQs of 1,000-2,000 units create significant financial vulnerability, particularly for product categories like rose vibrators that continue to evolve in design and functionality. Our analysis of retailer performance indicates that first-time orders exceeding 500 units increase obsolescence risk by approximately 35% compared to smaller initial purchases.

The ability to conduct meaningful market testing fundamentally depends on reasonable MOQs. The optimal testing strategy involves:

Effective Product Testing Strategy

| Order Phase | Recommended Quantity | Purpose | Timeline |

|---|---|---|---|

| Initial Test | 100-200 units | Market validation | 30-45 days |

| Secondary Test | 300-500 units | Preference refinement | 45-60 days |

| Full Launch | 500+ units | Optimized inventory | Ongoing |

This progressive approach allows retailers to gather critical customer feedback and performance data before making substantial inventory commitments. For example, when we introduced a new variation in our couples toys category last year, the initial 200-unit test revealed specific improvement opportunities that were incorporated into the subsequent production run, significantly enhancing customer satisfaction and reducing returns.

Product range diversity directly correlates with MOQ requirements. When capital must be allocated to meet high minimums for each SKU, retailers inevitably limit their product range breadth. Our most successful retail partners typically maintain 15-25 distinct SKUs within the rose vibrator category alone, addressing different price points, feature sets, and aesthetic preferences. This diversity becomes financially unsustainable under high minimum order constraints.

Capital allocation efficiency improves dramatically with flexible MOQs. Consider the following comparative scenario for a retailer with $50,000 to allocate to rose vibrator inventory:

- High MOQ Scenario (1,000 units minimum): 3-5 distinct products

- Flexible MOQ Scenario (200-500 units): 8-12 distinct products

The latter scenario not only reduces risk exposure but significantly enhances the retailer's ability to serve diverse customer preferences and price points.

Response time to market trends represents another critical factor affected by minimum order requirements. The adult toy market continues to evolve rapidly, with design innovations and feature enhancements emerging regularly. Retailers constrained by high MOQs typically refresh inventory 2-3 times annually, while those working with flexible manufacturers can implement 6-8 inventory refreshes, maintaining consistently current product offerings.

For male adult toys and other categories including rose vibrators, we've implemented a graduated minimum order program that reduces initial order requirements to 200 units for first-time orders, increasing to standard levels as the partnership develops. This approach has resulted in 65% higher client retention rates compared to fixed minimum policies.

The operational realities of manufacturing do create legitimate minimum production requirements. However, manufacturers focused on building sustainable retail partnerships have developed innovative approaches to accommodate smaller orders, including:

- Consolidated production runs across multiple clients

- Color batch grouping to achieve production efficiencies

- Scheduled production windows that consolidate smaller orders

- Inventory banking programs for reliable clients

These approaches allow quality-focused manufacturers to maintain production efficiency while offering the flexible ordering terms essential for retail success.

How can you navigate pricing and negotiation when sourcing rose vibrators?

I used to accept the first price quoted by manufacturers. Learning effective negotiation strategies has since saved my company thousands of dollars while maintaining product quality.

When negotiating rose vibrator wholesale pricing, understand production cost structures, utilize tiered volume commitments, consider quality-price relationships, evaluate payment term options, and calculate total acquisition costs beyond unit price. Effective negotiation balances price considerations with quality requirements and partnership potential.

The pricing negotiation process for rose vibrators follows distinct patterns that savvy retailers can navigate to secure favorable terms without compromising product quality. Throughout my experience at VF Pleasure, I've developed systematic approaches to pricing discussions that benefit both retailers and manufacturers.

Understanding actual production cost structures provides the foundation for effective negotiation. Rose vibrators typically include the following key cost components:

- Silicone materials ($1.20-2.50 per unit depending on quality grade)

- Motor assembly ($1.50-3.80 based on performance specifications)

- Electronic components and circuit board ($0.90-2.20)

- Battery ($0.70-1.80 depending on capacity and quality)

- Assembly labor ($0.40-1.20 based on complexity)

- Packaging ($0.30-2.00 ranging from simple to premium)

- Quality control procedures ($0.20-0.80)

- Manufacturer margin (typically 15-25%)

This cost breakdown reveals where quality compromises often occur when prices are pushed too low. For example, a rose vibrator priced below $7 wholesale typically indicates the use of lower-grade silicone or reduced battery capacity – factors that directly impact consumer satisfaction.

Tiered volume commitment strategies offer an effective approach to securing favorable pricing while maintaining reasonable initial order quantities. We typically structure agreements with the following framework:

- Initial order: 200-300 units at standard pricing

- 60-day follow-up: 500+ units at 5-8% discount

- 90-day projection: 1,000+ units at 10-15% discount

- Annual commitment: Predefined volume with 15-20% discount

This approach provides manufacturers with valuable forecasting data while allowing retailers to maintain inventory flexibility. The progressive structure also creates natural decision points for evaluating product performance before increasing commitments.

Quality-price relationship analysis prevents costly mistakes in pursuit of lowest possible pricing. Our empirical data shows that rose vibrators with wholesale prices 25-35% higher than market averages typically demonstrate:

- 40-60% lower return rates

- 70-85% higher reorder probability from consumers

- 30-50% longer functional lifespan

These factors create substantially higher lifetime value than the initial price differential, making strategic quality investments financially sound decisions rather than simply higher costs.

Payment term negotiation often yields more significant financial benefits than marginal unit price reductions. Standard industry terms typically require 30% deposits with 70% payment before shipment. However, established retailers can negotiate more favorable structures such as:

- Reduced deposits (15-20%) for regular customers

- Net 30 terms for portion of payment for established relationships

- Staggered shipment schedules with corresponding payment timelines

- Trial order arrangements with reduced upfront commitment

These payment structures improve cash flow management and reduce working capital requirements, often providing greater financial benefit than 2-3% reductions in unit pricing.

Total acquisition cost analysis prevents common sourcing mistakes that focus exclusively on unit price. Beyond the base product cost, comprehensive analysis should include:

- Shipping costs (significantly impacted by order volume)

- Import duties and customs fees (typically 6-12% for adult products)

- Quality control costs (third-party inspection when needed)

- Defect allowances and return policies

- Warranty support infrastructure

- Payment processing fees (especially for international transfers)

We recently analyzed two competing supplier options for a retail partner – one offering units at $8.50 and another at $9.20. When factoring all acquisition costs, the apparently more expensive supplier actually delivered a 4% lower total cost due to more favorable shipping terms and significantly lower defect rates.

For new retailers entering the market, establishing negotiation credibility requires specific approaches. Manufacturers evaluate potential clients not just on current order volume but on perceived growth potential and partnership value. Effective strategies include:

- Providing detailed business plans demonstrating growth trajectory

- Sharing market position and distribution channel information

- Establishing communication consistency and professional follow-through

- Making modest initial commitments and reliably fulfilling obligations

These approaches signal long-term partnership potential that often translates into preferential pricing and terms even for initial orders with limited volume.

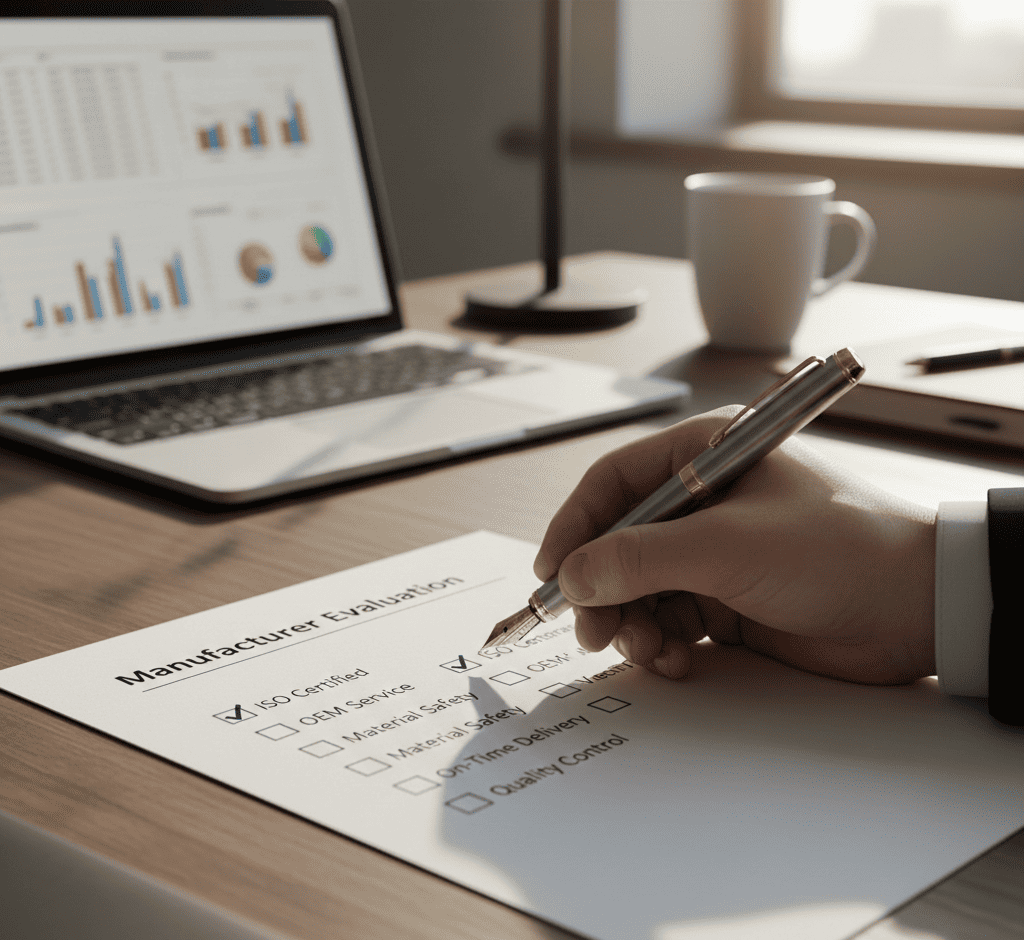

How do you evaluate potential rose vibrator manufacturers beyond price and MOQ?

After an early supplier relationship deteriorated due to communication problems, I learned to assess manufacturers on multiple dimensions that go beyond simple price comparisons.

When evaluating rose vibrator manufacturers, assess communication responsiveness and language capability, production capacity and scheduling flexibility, quality control systems and certification documentation, product development capabilities, and ethical manufacturing practices. These factors predict long-term relationship success beyond initial pricing.

The comprehensive evaluation of potential manufacturing partners requires systematic assessment across multiple operational dimensions. At VF Pleasure, our supplier qualification process has evolved through years of experience to identify manufacturers capable of sustaining quality production and responsive partnership.

Communication infrastructure represents a fundamental but often overlooked evaluation criterion. Effective manufacturing partnerships require clear, timely communication across time zones and language barriers. Our assessment protocol includes:

- Response time testing through staggered inquiries at different times

- Assessment of English language proficiency among key points of contact

- Clarity of technical communication when discussing specifications

- Transparency regarding production challenges and limitations

- Available communication channels and backup contacts

Manufacturers demonstrating strong communication capabilities typically resolve production challenges more efficiently and maintain schedule integrity more consistently than those with limited communication infrastructure.

Production capacity assessment extends beyond simple capability statements to include verification of:

- Actual vs. claimed manufacturing capacity through reference checks

- Staff size and training programs for production consistency

- Equipment age and maintenance schedules

- Backup systems for critical production components

- Production scheduling transparency and flexibility

During facility visits, we pay particular attention to production flow efficiency and quality control integration within manufacturing processes. Manufacturers with systematically organized production floors and clear quality control checkpoints consistently deliver more reliable products than those with chaotic production environments.

Quality control systems provide crucial insights into manufacturing reliability. Our evaluation includes:

Quality System Assessment Points

| Assessment Area | Evaluation Method | Significance |

|---|---|---|

| Material Testing | Verification of testing equipment and logs | Ensures consistent material quality |

| In-Process QC | Direct observation of inspection points | Identifies issues before completion |

| Finished Product Testing | Review of test protocols and records | Confirms systematic final verification |

| Defect Tracking | Analysis of defect tracking systems | Indicates continuous improvement focus |

| Certification Documentation | Verification of ISO and other certifications | Demonstrates commitment to standards |

The most reliable manufacturers maintain comprehensive defect tracking systems that categorize and quantify production issues, with clear evidence of corrective actions implemented to address recurring problems.

Product development capabilities significantly impact a manufacturer's ability to create competitive rose vibrators as the category evolves. Our evaluation focuses on:

- Internal engineering team size and capabilities

- Prototyping equipment and methodologies

- Development timeline history for previous products

- Willingness to sign appropriate intellectual property protections

- Examples of successful product innovations

Manufacturers with robust development capabilities not only produce existing designs efficiently but contribute valuable insights to product improvements and innovations that help retailers maintain market competitiveness.

Ethical manufacturing practices have gained increasing importance as consumers become more conscious of supply chain ethics. Our assessment includes:

- Labor practices and compliance with local regulations

- Environmental management systems and waste disposal

- Materials sourcing transparency

- Factory working conditions and worker welfare

- Community engagement and corporate responsibility initiatives

Beyond ethical considerations, these factors correlate strongly with overall manufacturing reliability and risk management. Factories demonstrating strong ethical commitments typically maintain more stable workforces, experience fewer production disruptions, and demonstrate greater operational consistency.

For retailers considering manufacturer partnerships, on-site visits provide invaluable insights impossible to gather through remote communication. During facility tours, we recommend focusing special attention on:

- Cleanliness and organization of production areas

- Worker engagement and supervision approaches

- Material storage conditions and inventory management

- Quality control implementation throughout the facility

- Sample retention and reference systems

These observations often reveal more about a manufacturer's capability than formal presentations or capability statements. For retailers unable to conduct in-person visits, third-party inspection services can provide objective facility assessments using standardized protocols.

Conclusion

Successful rose vibrator sourcing requires balancing quality, customization, and MOQ considerations. By thoroughly evaluating manufacturers beyond price, implementing strategic customization, and negotiating flexible terms, retailers can develop distinctive product offerings while managing inventory risk and maintaining strong profit margins.