You've probably wondered how those intimate products make their way from concept to your bedroom drawer. The adult toy manufacturing process involves strict quality controls, specialized materials, and precision engineering that most people never see.

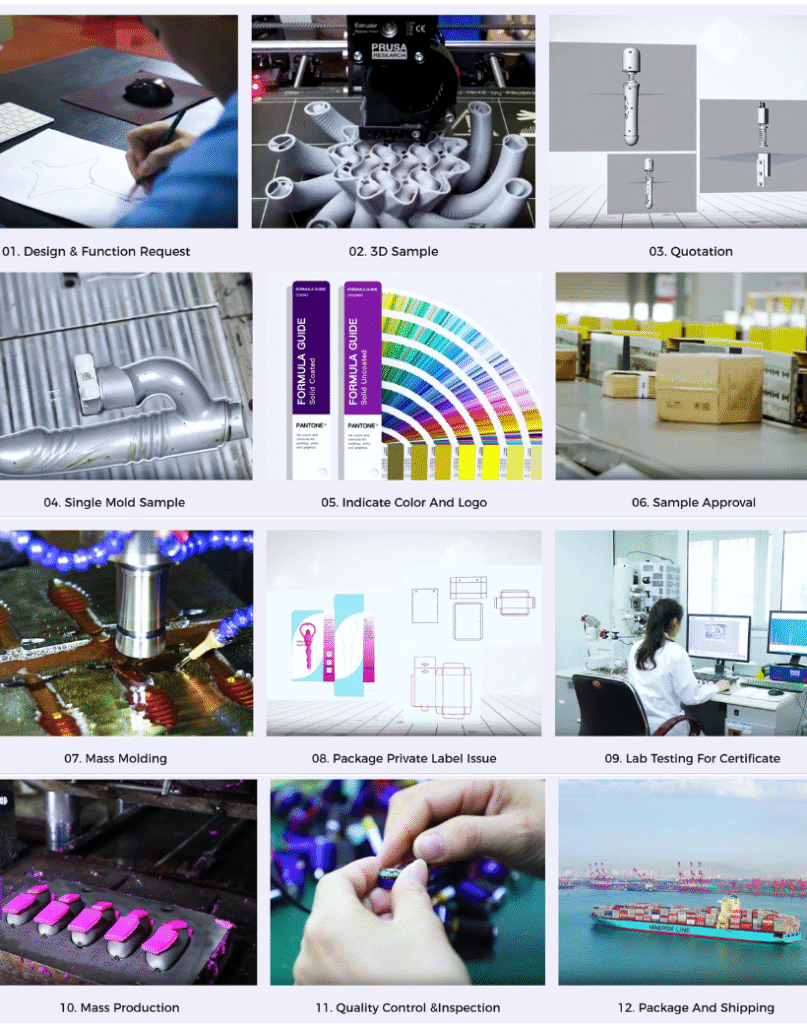

Adult toy manufacturing follows a structured 6-8 week process involving design consultation, R&D prototyping, precision tooling, multi-stage production with quality controls, and compliance verification - all requiring specialized equipment and food-grade materials to ensure safety and functionality.

After 15 years running VF Pleasure and our DongGuang facility, I've seen this industry evolve dramatically. Let me walk you through exactly how we transform ideas into market-ready products.

How Does the Design and Development Phase Work?

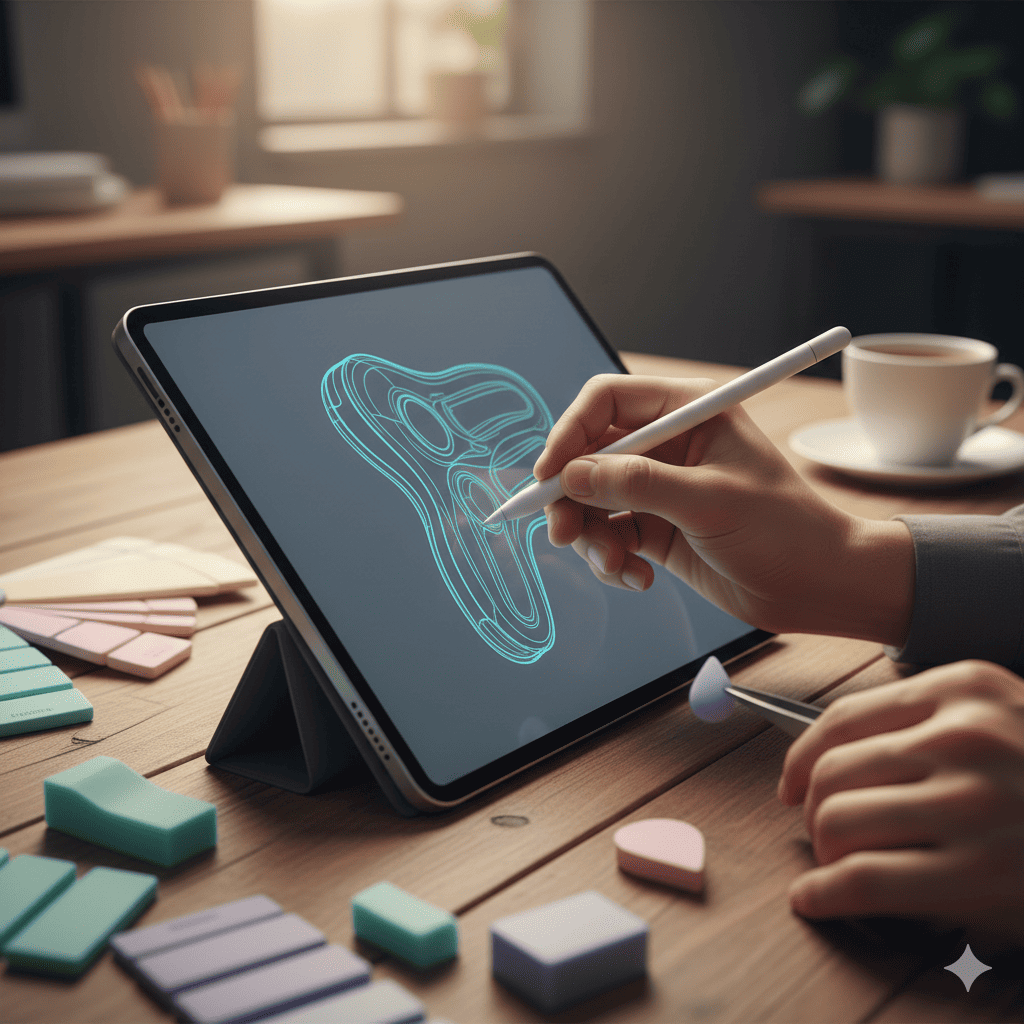

Your journey starts before any manufacturing begins. We need to understand your market positioning and user requirements completely.

The design phase involves detailed client consultations, CAD modeling, 3D prototyping, and material compatibility testing to validate concepts before expensive tooling investment.

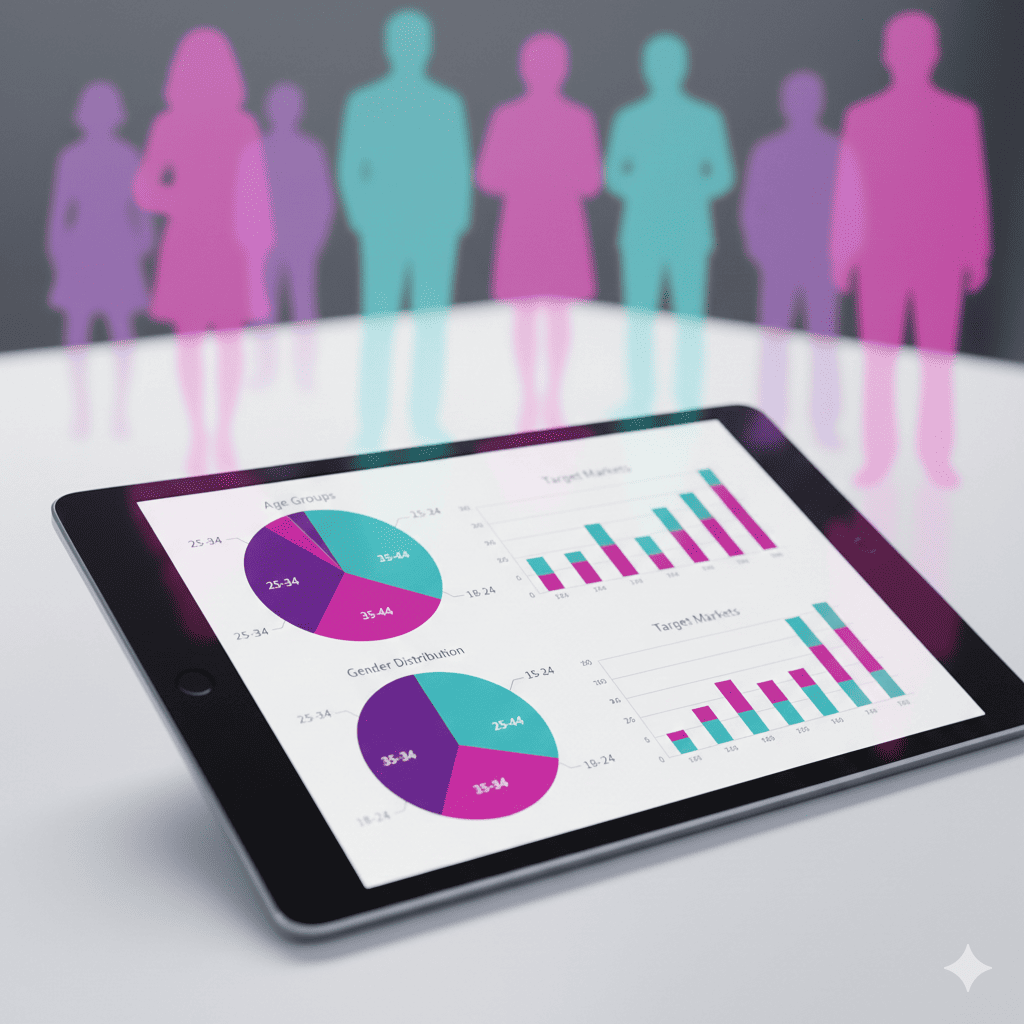

I start every project with comprehensive client consultations. You tell me your target demographic, price points, and functionality requirements. Our R&D team then creates initial concepts using professional CAD software.

This isn't just sketching ideas. We're engineering products that must function reliably under specific conditions. Motors need precise positioning. Wall thickness affects both flexibility and durability. Battery placement impacts weight distribution.

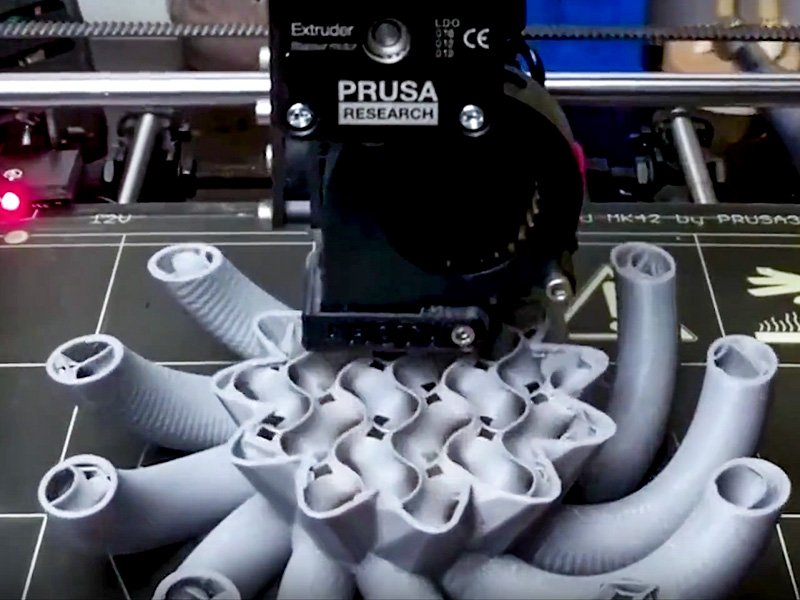

We use 3D printing1 for rapid prototyping to validate initial forms. This lets you hold and examine the concept before committing to expensive tooling. Material compatibility testing happens early too - particularly crucial when working with food-grade platinum silicone and medical-grade materials.

The testing phase reveals potential issues. Maybe the motor housing creates unwanted vibration transfer. Perhaps the silicone formulation needs adjustment for the desired firmness. We resolve these problems now, not during production.

| Design Phase Component | Timeline | Purpose |

|---|---|---|

| Client Consultation | 1-2 days | Requirements gathering |

| Concept Development | 3-5 days | Initial design creation |

| 3D Prototyping | 2-3 days | Physical validation |

| Material Testing | 1-2 weeks | Safety verification |

| Design Refinement | 3-5 days | Issue resolution |

What Happens During Pre-Production Planning?

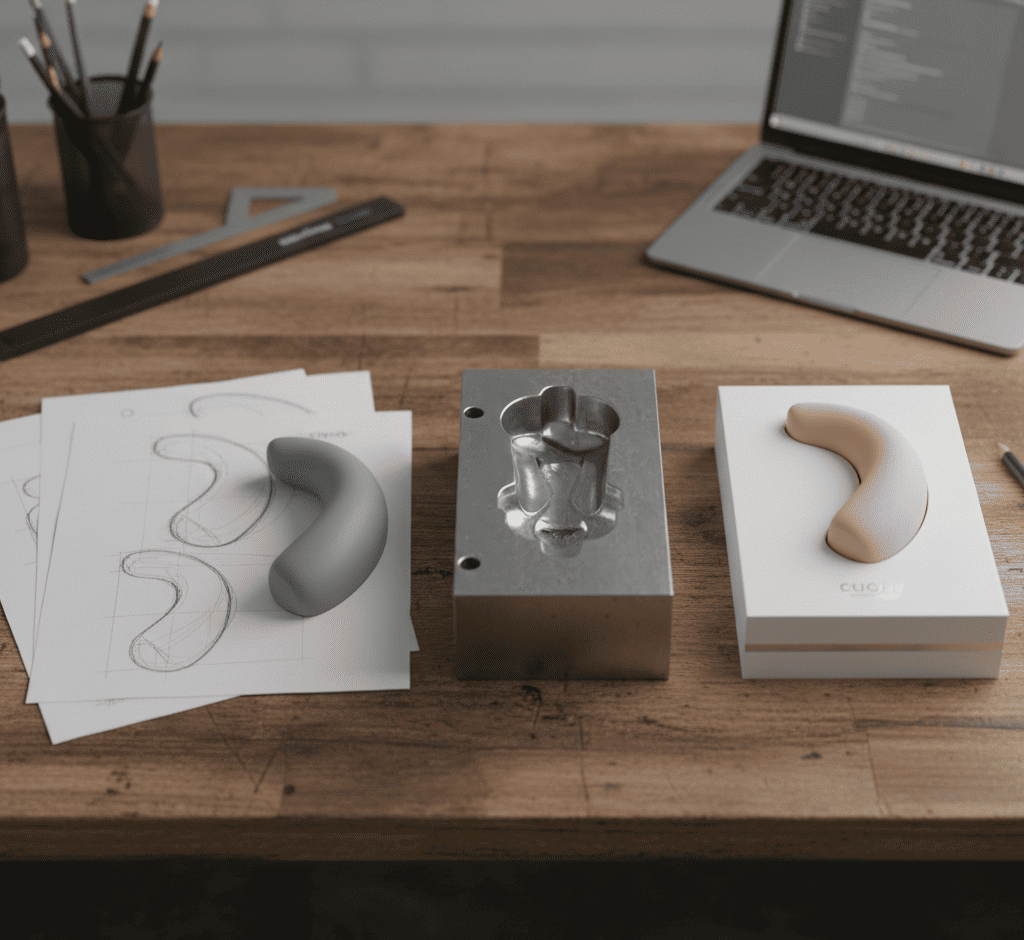

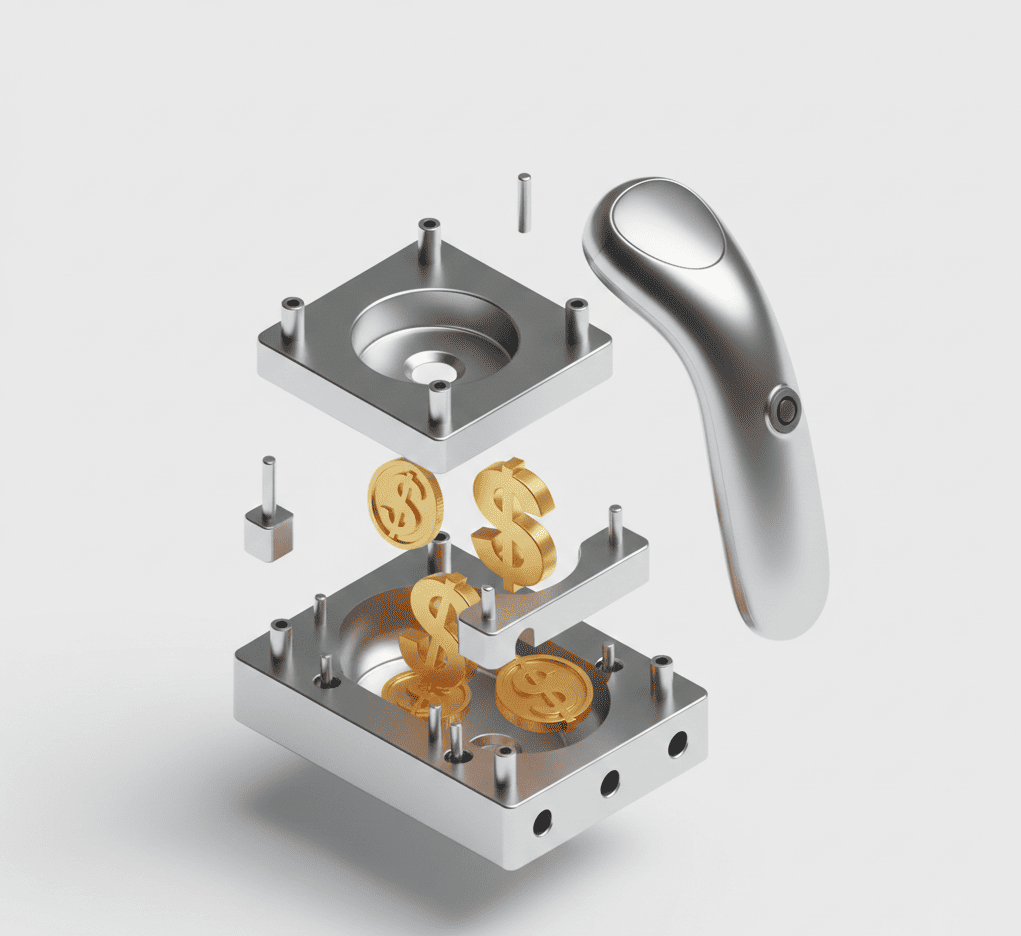

Pre-production determines whether your product succeeds or fails. This phase focuses on tooling development and pilot testing.

Pre-production involves creating precision molds, developing quality tooling investment, running pilot batches, and validating functionality before full production commitment.

Tooling development is absolutely critical. For custom sex toys using silicone, we create precision molds ensuring consistent wall thickness and proper curing temperatures.

I've learned that investing in high-quality steel tooling upfront prevents costly production delays later. Cheap aluminum molds might save money initially, but they wear quickly and produce inconsistent results.

Our tooling engineers consider every detail. Parting lines must be positioned where they won't affect user experience. Vent placement prevents air bubbles during silicone casting2. Gate locations minimize visible marks on finished products.

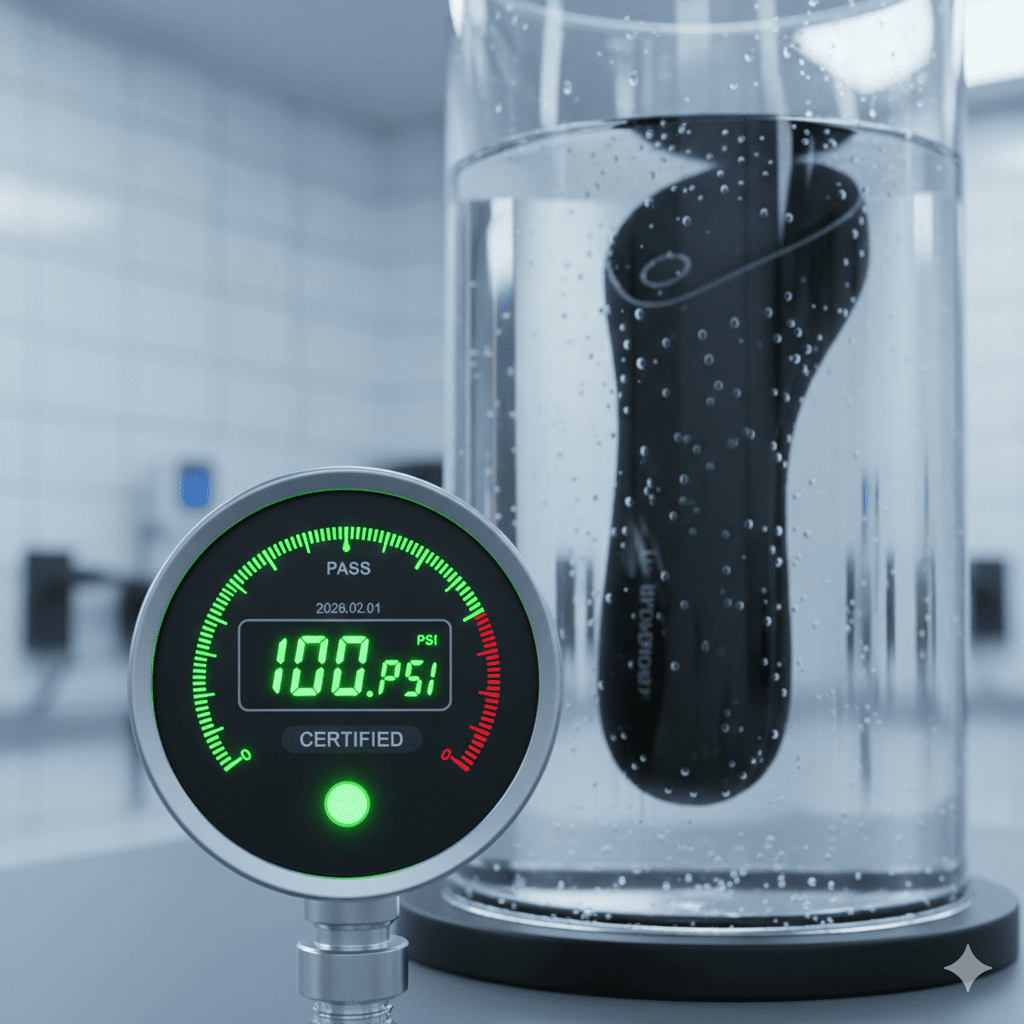

We run pilot batches to validate functionality. Motors get tested for vibration patterns and battery life. Waterproofing undergoes submersion testing. Electronic components face temperature cycling to ensure reliability.

This phase also involves supply chain coordination. We source food-grade silicone from certified suppliers. Electronic components come from factories meeting our quality standards. Packaging materials get arranged based on your private label requirements.

The pilot testing reveals manufacturing challenges. Maybe our silicone cure cycle needs adjustment. Perhaps assembly sequence requires modification for efficiency. We solve these issues before committing to full production runs.

How Does the Manufacturing Process Actually Work?

Manufacturing transforms validated designs into finished products through multiple specialized processes. Our production lines handle different materials and components simultaneously.

Manufacturing involves injection molding for rigid components, silicone casting for body-safe materials, precision motor assembly, multi-stage quality control, and final packaging integration.

Our adult toy factory operates specialized production lines for different materials and product types. Injection molding3 handles ABS plastic components like battery housings and control panels. These require precise temperature control and consistent cycle times.

Silicone casting4 happens in clean-room environments. We mix platinum-cure silicone to exact specifications, then inject it into heated molds. Curing temperatures and times vary based on wall thickness and silicone durometer.

Motor integration requires precision assembly. Vibrator motors get positioned exactly where designs specify. Wiring harnesses route through product interiors without creating stress points. Battery connections use corrosion-resistant materials.

Quality control5 happens at every manufacturing stage. Incoming material inspection verifies food-grade certifications and material properties. In-process monitoring checks dimensions, cure completeness, and assembly alignment.

Final product testing includes functionality verification, waterproof testing, and packaging integrity checks. Every vibrator gets powered on to verify motor operation and vibration patterns.

Our production capacity varies by product complexity. Simple single-motor products might complete 1,000 units daily per line. Complex multi-function products with advanced electronics might produce 200-300 units daily.

Batch documentation6 tracks every component from raw materials through finished goods. This traceability supports quality investigations and regulatory compliance requirements.

| Manufacturing Stage | Process Type | Quality Checks |

|---|---|---|

| Component Molding | Injection/Casting | Dimensional verification |

| Motor Integration | Precision assembly | Functionality testing |

| Electronics Assembly | Manual/Automated | Electrical testing |

| Final Assembly | Manual | Complete functionality |

| Packaging | Automated | Integrity verification |

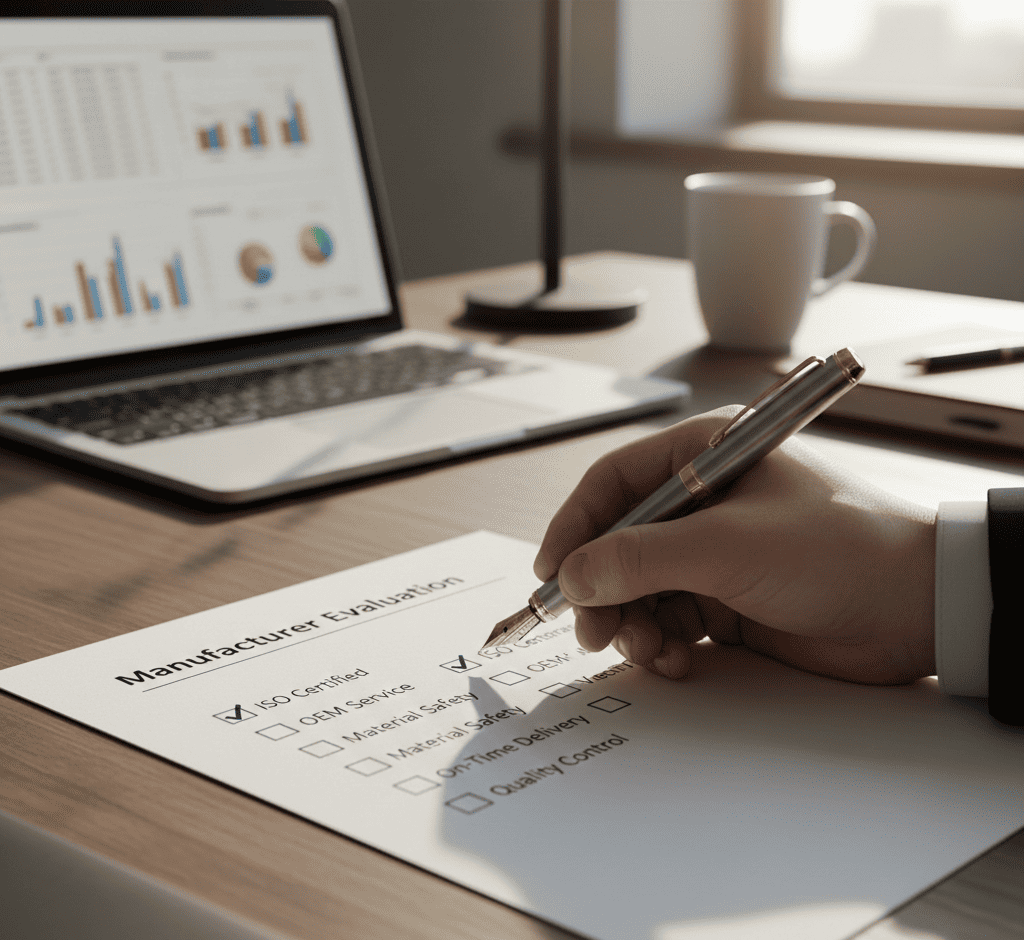

What Are the Compliance and Finishing Requirements?

Final production phases ensure products meet regulatory requirements and customer specifications. This determines market acceptance and legal compliance.

Compliance and finishing involve regulatory verification for target markets, custom packaging development, final quality assurance, batch documentation, and shipment preparation.

Regulatory compliance verification happens before any products ship. Different markets have varying requirements. European CE marking requires specific material certifications and electrical safety testing. US FDA guidelines affect materials and labeling.

We maintain relationships with certified testing laboratories. Products undergo biocompatibility testing7, electrical safety verification, and chemical analysis. Documentation packages support customs clearance and regulatory submissions.

Packaging customization reflects your brand identity. Private label sex toys receive custom packaging featuring your branding, product information, and regulatory statements.

Package design considers retail environments and shipping requirements. Discreet packaging options protect consumer privacy. Retail-ready packaging supports merchandising and point-of-sale presentation.

Final quality assurance includes complete product testing and packaging integrity verification. We simulate shipping conditions to ensure products arrive undamaged. Random sampling validates ongoing production quality.

Batch documentation provides complete traceability from raw materials through finished goods. This supports quality investigations, regulatory inquiries, and customer service requirements.

Our wholesale sex toys services include inventory management and drop-shipping capabilities. Products can ship directly to your customers or transfer to your distribution facilities.

Conclusion

Creating adult toys involves sophisticated manufacturing processes requiring specialized expertise, quality materials, and strict compliance protocols across design, production, and finishing phases.

-

Explore how 3D printing can enhance your product development process, offering rapid prototyping and design validation. ↩

-

Learn about the silicone casting process and its importance in producing durable and safe products. ↩

-

Explore this link to understand how injection molding works and its significance in producing high-quality components. ↩

-

Learn about silicone casting techniques and their applications in creating durable and safe products. ↩

-

Discover essential quality control practices that ensure product reliability and compliance in manufacturing. ↩

-

Find out how batch documentation enhances traceability and supports quality investigations in production. ↩

-

Exploring biocompatibility testing helps ensure that products are safe for consumer use and meet health standards. ↩