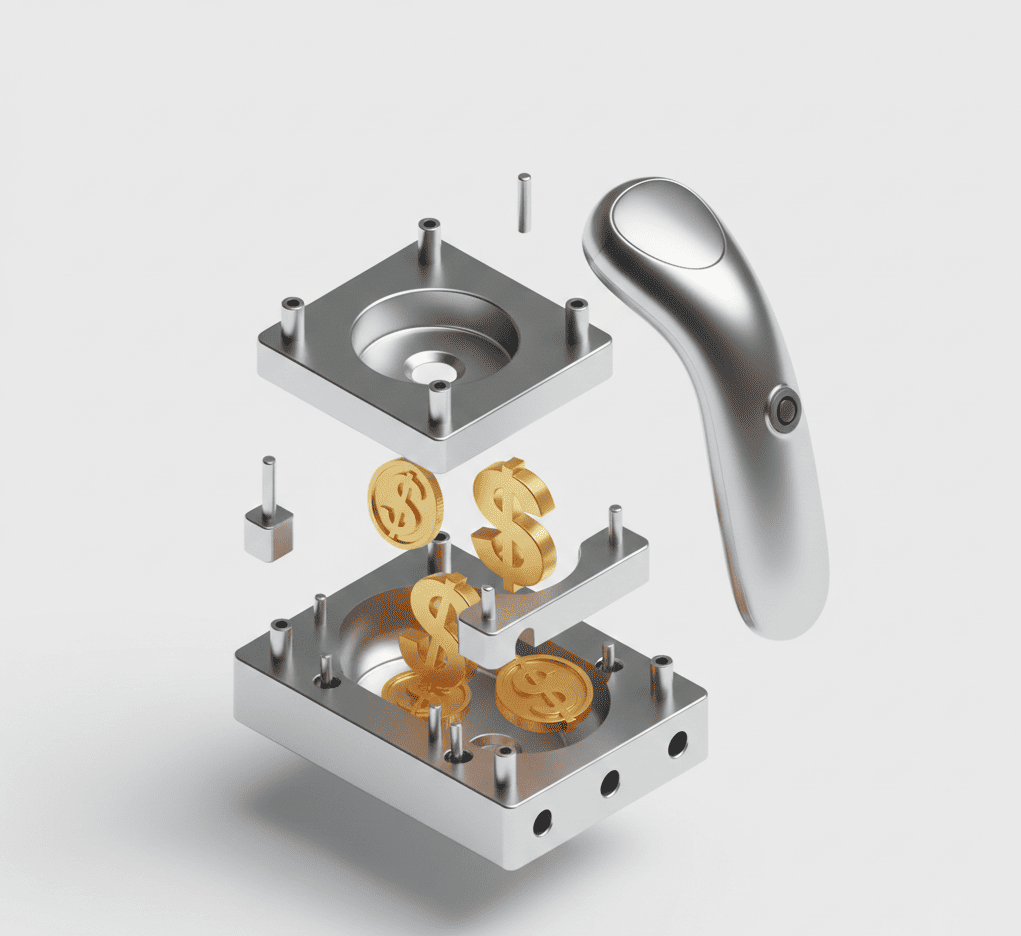

Opening a private mold for vibrators requires significant upfront investment. Most adult toy manufacturers quote $15,000-$50,000 for custom tooling, but actual costs vary dramatically based on materials and complexity.

Private mold costs for vibrators range from $2,000 for basic silicone molds to $80,000 for complex liquid injection tooling. Plastic injection molds typically cost $20,000-$40,000, while silicone molds offer lower initial investment but higher per-unit production costs.

After 15 years running VF Pleasure, I've helped hundreds of brands navigate mold investment decisions. The biggest mistake I see? Focusing only on initial tooling costs without considering long-term production economics. 😤

💡 Pro Tip: Most successful brands budget 30-50% more than initial mold quotes to cover hidden costs and modifications.

What Factors Determine Silicone Mold Costs? 🔬

Understanding silicone tooling requires examining multiple cost layers. Most brands underestimate the complexity involved in custom adult toy manufacturing.

Silicone mold costs vary from $2,000 for basic compression molds to $80,000 for liquid injection systems. Material complexity, cavity count, and precision requirements drive pricing differences significantly.

Basic Silicone Compression Molds 🛠️

Simple compression molds represent the most affordable entry point. These tools work well for basic shapes without complex internal features.

Our factory typically quotes $2,000-$5,000 for basic compression tooling. However, mold lifespan remains limited to 50-100 cycles before replacement becomes necessary.

⚠️ Important: Compression molds have shorter lifespans but lower upfront costs - perfect for testing market demand.

Per-unit costs with compression molding:

- Food-grade platinum silicone: $80/kg material cost

- 50-gram vibrator production: approximately $15 per unit

- Labor and processing: $3-5 per unit additional

Advanced Liquid Injection Molding 🚀

Complex custom vibrators require sophisticated liquid injection systems. These molds enable precise wall thickness control and intricate internal geometries.

Investment ranges from $50,000-$80,000 for multi-cavity liquid injection tools. Higher upfront costs deliver superior part consistency and faster cycle times.

Liquid injection advantages:

- ✅ Consistent wall thickness throughout complex shapes

- ✅ Reduced material waste compared to compression molding

- ✅ Higher production speeds for volume manufacturing

- ✅ Superior surface finish quality

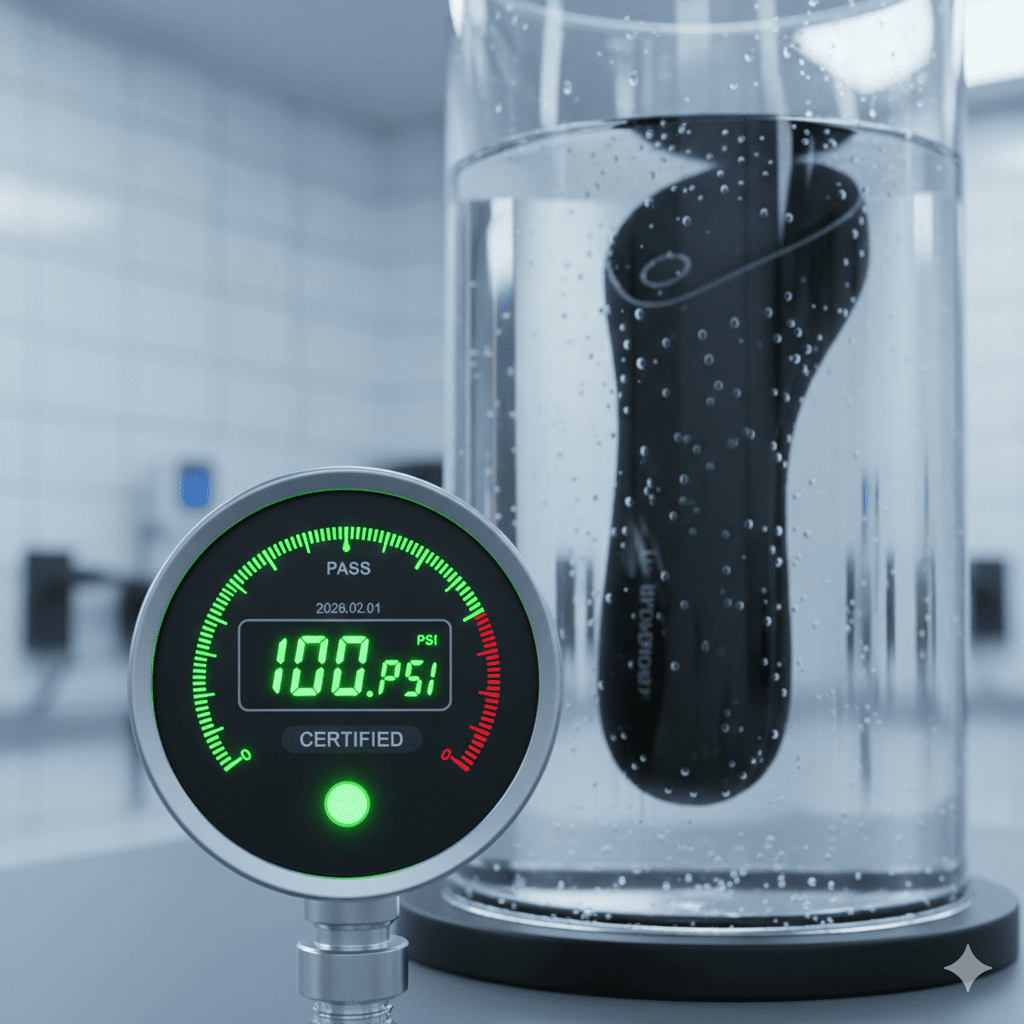

Material Selection Impact 🎯

Platinum-cure silicone demands different tooling approaches than standard grades. Medical-grade materials require specialized handling and processing equipment.

Our body-safe materials guide covers certification requirements that affect mold design specifications.

📊 Cost Breakdown: Medical-grade certifications add 15-25% to base tooling costs but enable premium positioning.

How Much Do Plastic Injection Molds Cost? 💳

Plastic injection tooling offers different economics compared to silicone systems. Initial investment typically exceeds silicone options, but per-unit costs drop significantly.

Plastic injection molds for vibrators cost $20,000-$40,000 for standard tooling. Complex multi-cavity systems or specialized materials can push costs toward $60,000-$80,000 range.

Standard ABS Plastic Tooling 🔧

Most male adult toys and vibrator housings use ABS plastic construction. Standard injection molds offer excellent durability and production speeds.

Typical ABS tooling investment ranges $20,000-$30,000 for single-cavity systems. Multi-cavity tools increase costs but reduce per-unit production expenses.

| Cost Factor | Price Range | Notes |

|---|---|---|

| Material costs | $2-4 per kg | ABS plastic raw material |

| Cycle times | 30-60 seconds | Per part production speed |

| Mold lifespan | 500,000+ cycles | Typical durability expectation |

| Per-unit costs | $0.50-$2.00 | Depending on complexity |

Specialized Plastic Materials 🏆

Premium vibrators often require specialized plastics like medical-grade polycarbonate or TPE overmolding. These materials demand enhanced tooling specifications.

Our OEM adult toys manufacturing process accommodates various plastic grades based on product requirements.

🎨 Design Flexibility: Two-shot molding enables premium textures and color combinations but requires $40,000+ investment.

Specialized material considerations:

- 📈 Medical-grade certifications add 15-25% to tooling costs

- 🎯 Two-shot molding systems require $40,000+ investment

- 🎨 Surface texturing increases mold complexity significantly

- 🌈 Color-matching capabilities affect material selection

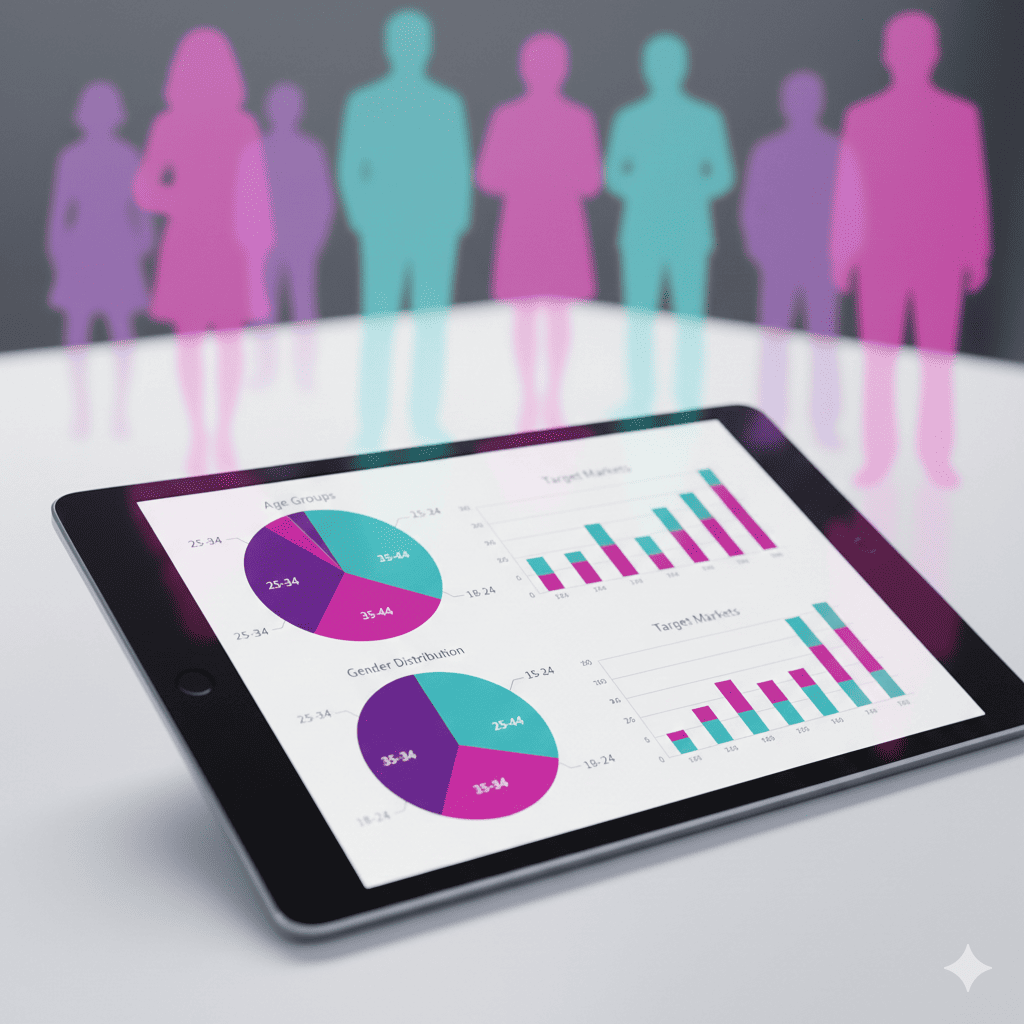

Production Volume Economics 📊

Break-even analysis determines optimal mold investment levels. Higher volume production justifies expensive tooling through reduced per-unit costs.

Most successful private label sex toys require minimum 10,000-unit annual volumes to justify custom tooling investment.

💰 ROI Reality Check: Custom tooling pays off when you're producing 15,000+ units annually. Below that threshold, consider ODM options first.

What Hidden Costs Should You Consider? 😱

Mold investment extends beyond initial tooling expenses. Smart manufacturers budget for ongoing maintenance, modifications, and production setup costs.

Hidden mold costs include maintenance ($2,000-$5,000 annually), design modifications ($3,000-$8,000), and production setup fees ($1,000-$3,000 per run). These expenses can add 30-50% to total investment.

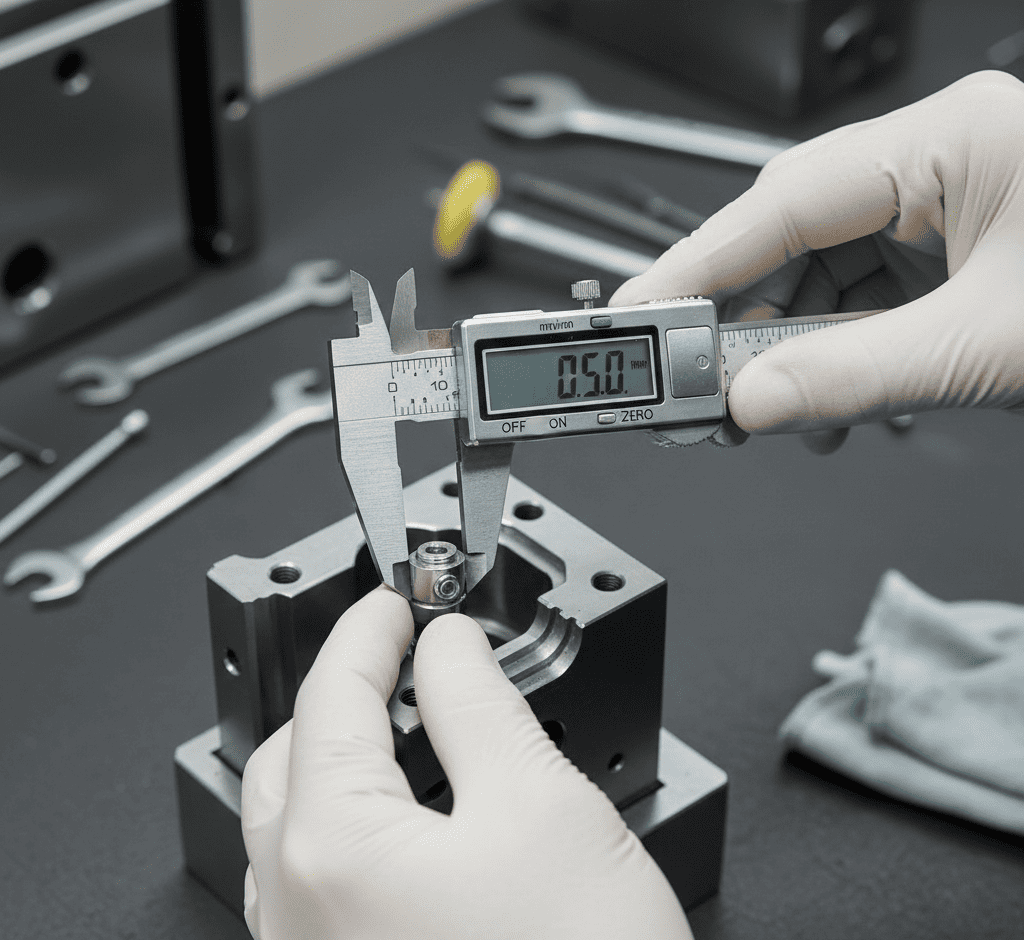

Mold Maintenance Requirements 🔧

Regular maintenance ensures consistent part quality throughout production runs. Silicone molds require more frequent attention than steel injection tools.

Silicone mold maintenance:

- 🧼 Surface cleaning after each production cycle

- 🔄 Replacement every 50-100 uses for compression molds

- ⚙️ Liquid injection systems need quarterly servicing

- 💸 Annual maintenance costs: $2,000-$3,000 typical

Plastic injection maintenance:

- 📅 Monthly preventive maintenance schedules

- 🔍 Annual deep cleaning and inspection

- 🔩 Component replacement every 2-3 years

- 💰 Maintenance costs: $3,000-$5,000 annually

Design Modification Expenses 🎨

Product improvements often require mold modifications. Our custom adult toy factory builds flexibility into initial tooling designs.

Typical modification costs range $3,000-$8,000 depending on complexity. Major design changes may require complete mold replacement.

⚠️ Smart Strategy: Design your mold with future modifications in mind. Modular tooling costs 10-15% more upfront but saves thousands later.

Production Setup Fees 📋

Each production run incurs setup costs regardless of quantity. Shorter runs spread these expenses across fewer units, increasing per-piece costs.

Setup fees typically range $1,000-$3,000 per production campaign. Our low MOQ manufacturing helps minimize these impacts.

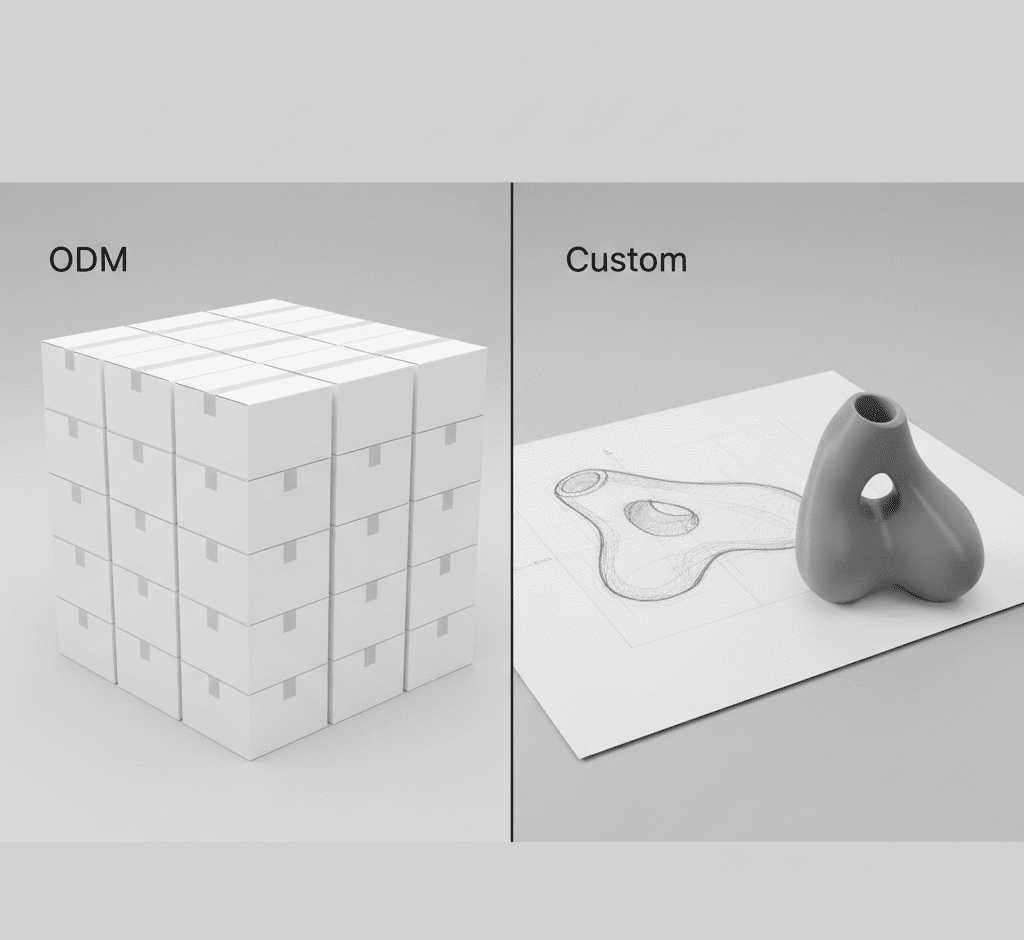

Should You Choose ODM Over Custom Molds? 🤔

ODM manufacturing offers alternative paths to market without custom tooling investment. Our ODM vs OEM comparison explains different approaches.

ODM manufacturing eliminates mold costs but limits customization options. Custom tooling provides complete design control at higher initial investment. Break-even typically occurs around 15,000-20,000 units annually.

ODM Cost Benefits 💡

Existing tooling reduces initial investment requirements significantly. Our wholesale adult toys catalog offers hundreds of proven designs.

🚀 Fast Track Option: ODM gets you to market 3-6 months faster than custom tooling while testing demand.

ODM advantages:

- ✅ Zero tooling investment required

- ⚡ Faster time-to-market execution

- 🎯 Proven design performance

- 📦 Lower minimum order quantities

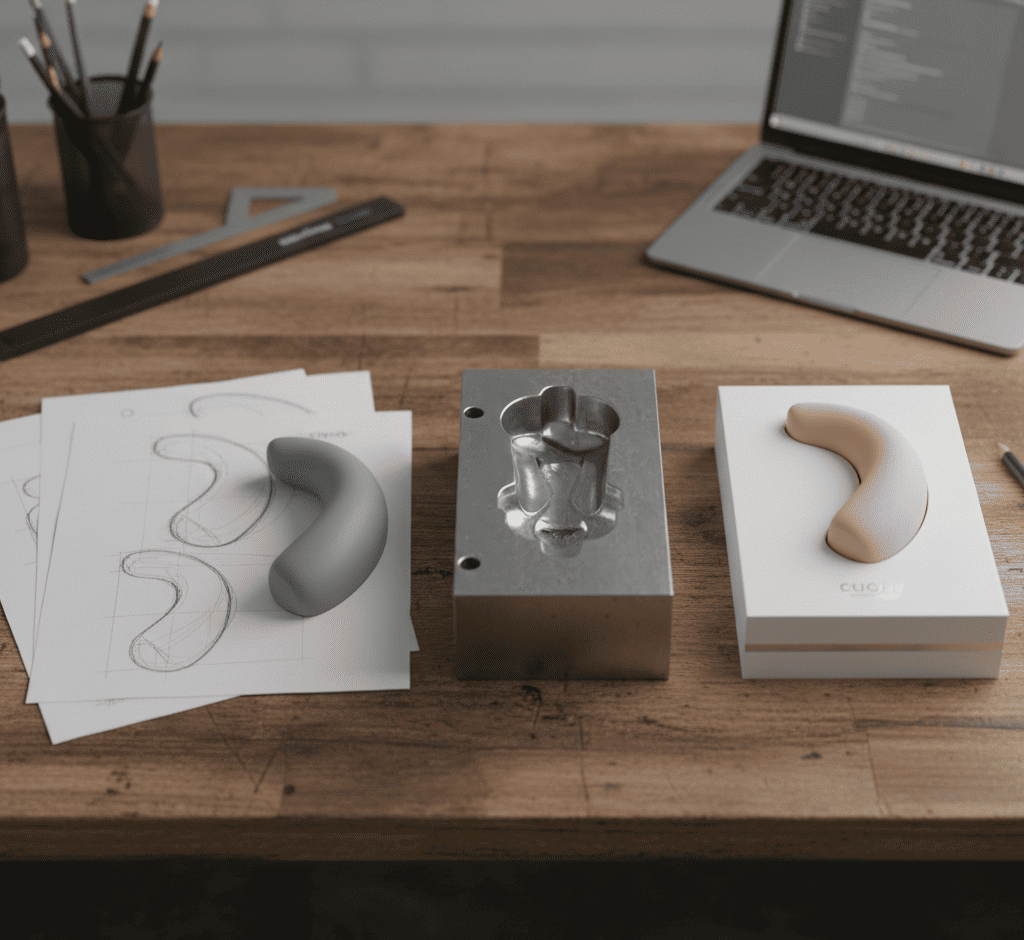

Custom Mold Advantages 🏆

Unique designs command premium pricing and stronger brand differentiation. Custom tooling enables exclusive product offerings competitors cannot replicate.

Our private label development process guides brands through custom tooling decisions.

Custom tooling benefits:

- 🎨 Complete design control and exclusivity

- 🔬 Optimal material selection for performance

- 📈 Scalable production for volume growth

- 💰 Enhanced profit margins through differentiation

Ready to Start Your Custom Mold Project? 🚀

Understanding mold costs is just the beginning. The real question is: which approach aligns with your business goals and budget?

📞 Get Expert Guidance: Schedule a free consultation with our engineering team to discuss your specific requirements and get accurate cost estimates for your project.

Next Steps:

- 📋 Define your product specifications and target volumes

- 💰 Set realistic budget expectations including hidden costs

- 🤝 Partner with experienced manufacturers like VF Pleasure

- 📊 Compare ODM vs custom tooling economics for your situation

Conclusion 🎯

Private mold costs vary dramatically based on materials, complexity, and volume requirements. Smart investment decisions balance initial tooling expenses against long-term production economics and market positioning goals.

Whether you choose $2,000 compression molds or $80,000 injection systems, success depends on matching tooling investment to your business strategy.

🎉 Ready to explore your options? Contact our team at VF Pleasure for personalized cost estimates and strategic guidance on your custom vibrator project.