Starting a sex toy business feels overwhelming. You worry about manufacturers, costs, and market entry. Many entrepreneurs fail because they lack a clear roadmap.

I launched VF Pleasure 15 years ago with one production line in Dongguan. Today, we operate 5-10 lines serving global retailers. My journey taught me that success comes from understanding manufacturing realities, building trust with suppliers, and focusing on quality over quick profits.

![]()

Let me share the real story behind building a successful adult toy manufacturing business. These lessons cost me years of mistakes and countless sleepless nights. 💪

- 1 What Were the Biggest Challenges When Starting Your Adult Toy Factory? 😰

- 2 How Did You Overcome Financial Constraints in the Beginning? 💰

- 3 What Mistakes Did You Make When Choosing Your First Manufacturer Partners? ❌

- 4 How Did You Build Trust With International Clients Initially? 🌍

- 5 What Role Did Trade Shows Play in Your Early Growth? 🎪

- 6 How Did You Develop Your First Custom Product Line? 🎨

- 7 What Would You Do Differently If Starting Again Today? 🔄

- 8 Conclusion 🎉

What Were the Biggest Challenges When Starting Your Adult Toy Factory? 😰

Starting felt like jumping into deep water without knowing how to swim. I had passion but no manufacturing experience.

The initial challenges included finding reliable suppliers for body-safe materials, understanding FDA and CE compliance requirements, securing factory space in Dongguan, and convincing retailers to trust an unknown Chinese manufacturer. Capital was tight—I started with savings of $50,000.

Understanding Material Safety Standards ⚠️

My first major hurdle was learning about body-safe materials. I didn't realize that not all silicone is created equal.

Medical-grade platinum silicone costs significantly more than regular silicone. I initially tried cutting costs with cheaper alternatives. That decision almost destroyed my reputation before it started.

💔 A potential client from Germany tested my early samples. They failed phthalate tests. I felt embarrassed and defeated.

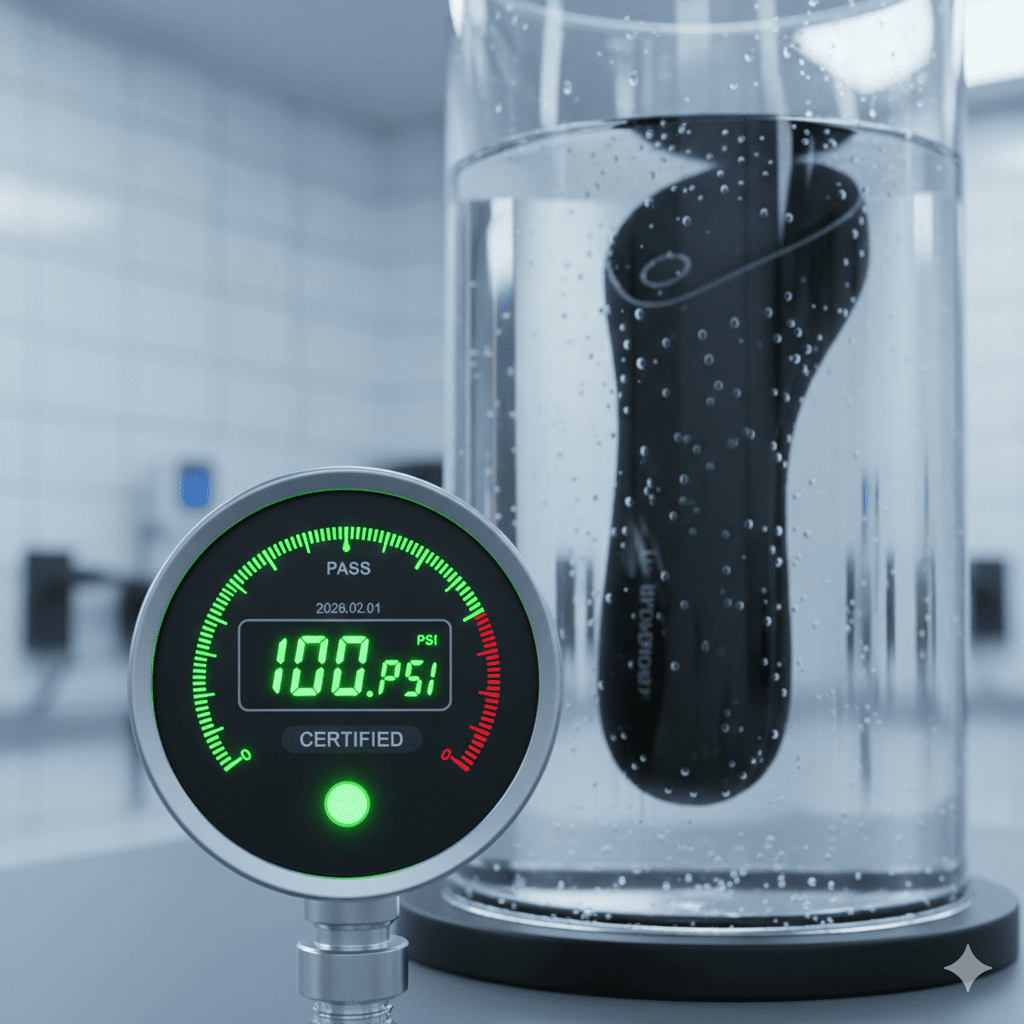

That failure taught me the most valuable lesson: never compromise on material safety. I invested in partnerships with certified silicone suppliers. I learned about ABS plastic grades. I studied glass manufacturing standards for niche products.

Today, VF Pleasure's manufacturing process prioritizes material transparency. Every batch includes certification documents. Our clients trust us because we learned this lesson the hard way.

Building the First Production Line 🏭

Setting up my first production line required $30,000. I rented a small space in Dongguan's industrial district.

I bought used molding machines from a closing factory. I hired three workers who had experience in general plastic manufacturing. None of us knew adult toy production specifics.

| Initial Setup Component | Cost (USD) | Time Required |

|---|---|---|

| 🔧 Molding Equipment | $15,000 | 2 months |

| 📦 Material Inventory | $8,000 | 1 month |

| 👷 Labor (3 workers) | $1,200/month | Ongoing |

| 🏢 Factory Rent | $800/month | Ongoing |

| ✅ Quality Testing Tools | $5,000 | 2 weeks |

We made mistakes constantly. Our first vibrator batch had motor alignment issues. Half the units buzzed at wrong frequencies. I personally inspected and reworked each defective unit.

Those early production runs taught me about quality control. I developed checklists that we still use today. Our quality standards guide reflects lessons from those painful first months.

💡 Pro Tip: Never launch without comprehensive quality testing protocols. The cost of recalls far exceeds investment in proper QC systems.

Finding My First Clients 🤝

Getting that first order felt impossible. Nobody knew VF Pleasure. Chinese manufacturers had mixed reputations.

I attended the Guangzhou Sex Culture Festival in 2010. I brought samples in a simple cardboard box. My English was basic. I felt intimidated by established manufacturers with fancy booths.

"I met David, a procurement manager from a US retail chain. He was skeptical but willing to test our products. That first order was only 500 units—barely profitable. But David's feedback transformed our business." 🙏

David pointed out design flaws I never noticed. He explained what US consumers expected. He shared market trends I didn't know existed.

Key lessons from my first client relationship:

- ✅ Listen more than you talk

- ✅ Welcome criticism as free consulting

- ✅ Prioritize relationships over immediate profits

- ✅ Document every piece of feedback

- ✅ Follow through on every promise

That relationship taught me about building partnerships with adult toy distributors. Today, we prioritize long-term relationships over quick sales. Our OEM and ODM services reflect client feedback accumulated over 15 years.

🎯 Ready to start your adult toy business with a proven partner? Contact VF Pleasure for a free consultation on custom manufacturing solutions.

How Did You Overcome Financial Constraints in the Beginning? 💰

Money was my constant worry. I couldn't sleep thinking about payroll and material costs.

I used a bootstrapping approach—reinvesting every profit into equipment and materials. I avoided bank loans initially because interest rates were high. Instead, I negotiated payment terms with suppliers and offered volume discounts to early clients for faster payments.

Managing Cash Flow Without External Funding 📊

My strategy was simple but difficult: keep expenses minimal and turn inventory quickly.

I lived in a small apartment near the factory. I worked 16-hour days, handling everything from production supervision to customer emails. My wife managed accounting and supplier relationships.

We negotiated 60-day payment terms with silicone suppliers. We offered clients 30-day terms. That 30-day gap gave us breathing room to manufacture and ship orders.

🔑 Key financial principles I followed:

- Never spend on unnecessary equipment

- Pay workers fairly but keep the team small

- Reinvest at least 70% of profits into business growth

- Maintain three months of operating expenses as reserve

- Avoid debt unless absolutely necessary

This conservative approach meant slow growth. But it kept VF Pleasure sustainable. We never faced the cash flow crises that killed many competitors.

Our wholesale pricing structure today reflects those early financial lessons. We build healthy margins while remaining competitive.

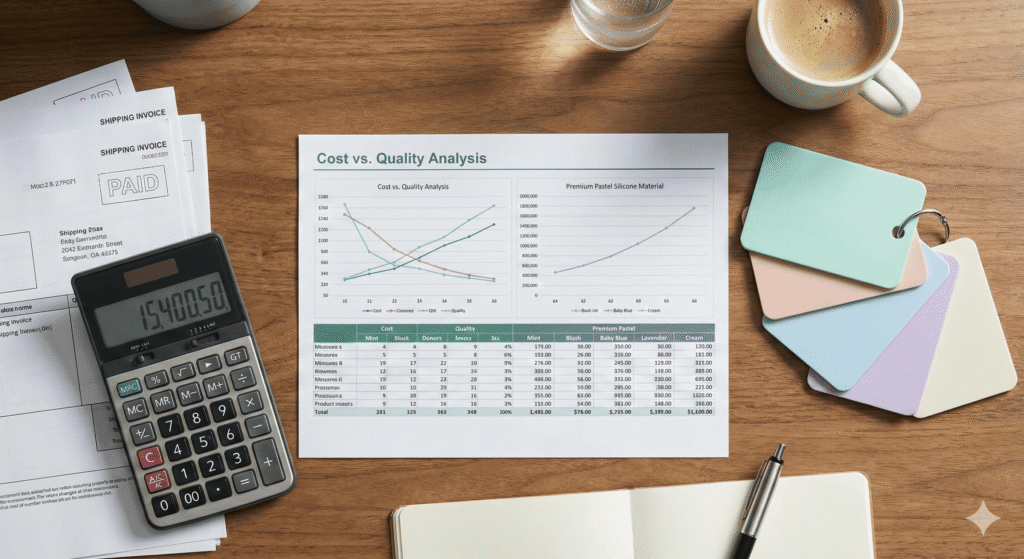

Scaling Production Gradually 📈

I didn't rush to buy new equipment. I maxed out our existing capacity first.

Our first production line could handle 2,000 units monthly. I pushed to reach that capacity before considering expansion. We worked night shifts. We optimized workflows constantly.

When revenue stabilized after year two, I bought a second molding machine. I hired two more workers. This gradual scaling prevented overextension.

| Year | Production Lines | Monthly Output | Team Size | Revenue (USD) |

|---|---|---|---|---|

| Year 1 | 1 | 1,200 units | 3 | $18,000 |

| Year 2 | 2 | 3,500 units | 5 | $52,000 |

| Year 3 | 3 | 6,000 units | 8 | $95,000 |

| Year 5 | 5 | 12,000 units | 15 | $185,000 |

Today, we operate 5-10 production lines depending on seasonal demand. Our custom adult toy manufacturing capabilities evolved through this disciplined growth approach.

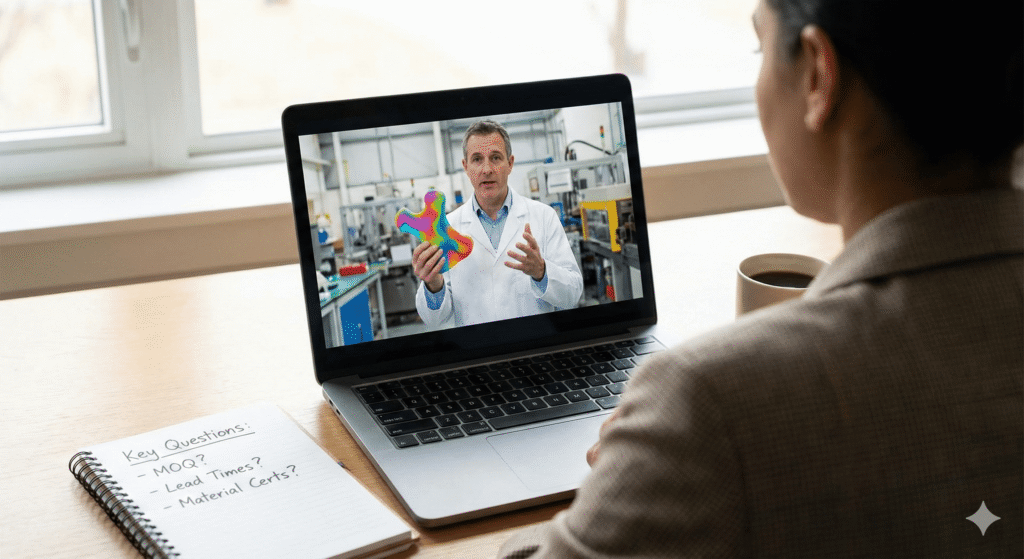

What Mistakes Did You Make When Choosing Your First Manufacturer Partners? ❌

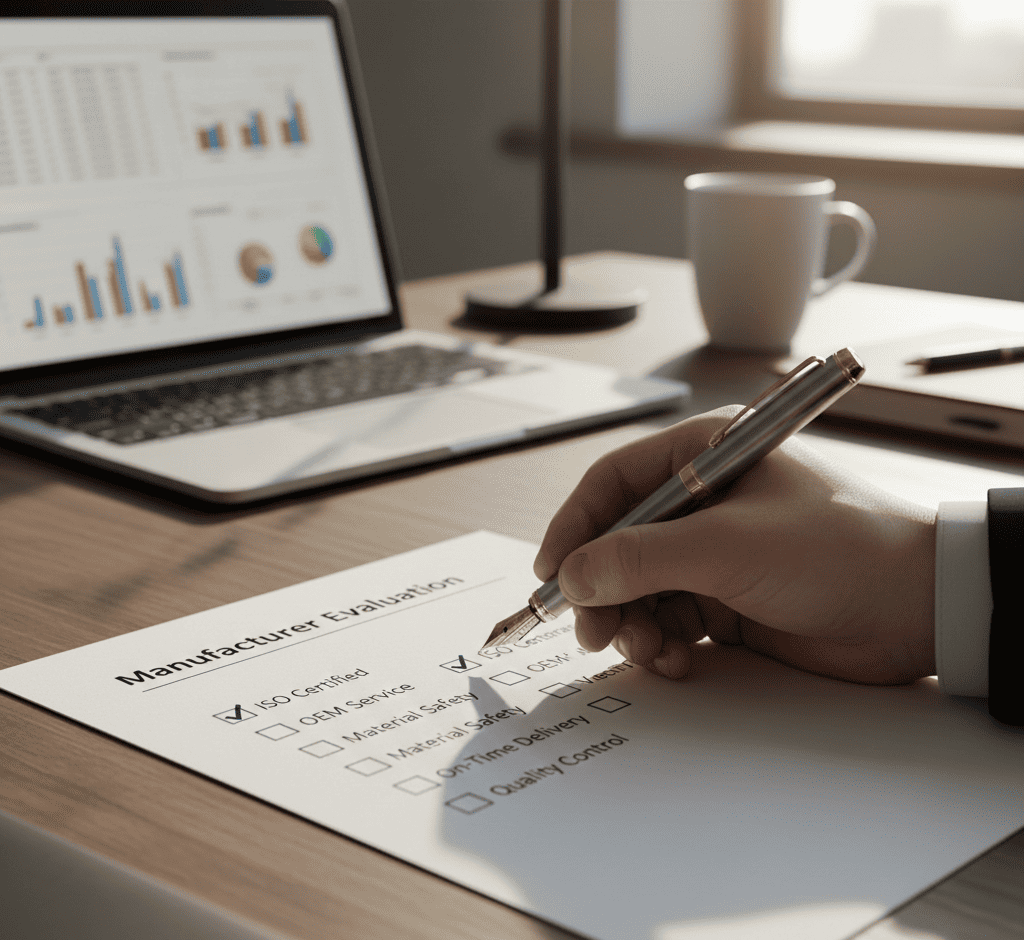

I made costly mistakes trusting the wrong suppliers. These errors taught me valuable lessons about due diligence.

My biggest mistake was prioritizing low prices over reliability. I chose a silicone supplier offering 20% below market rates. Their quality was inconsistent. We received contaminated batches that ruined production runs. I learned to verify certifications, visit facilities personally, and request sample batches before committing to partnerships.

The Contaminated Silicone Incident ☠️

This happened in my second year. I switched silicone suppliers to save $2 per kilogram.

The new supplier provided fake FDA certificates. I didn't verify thoroughly. We manufactured 3,000 vibrators with their material.

⚠️ A European client tested the products. The silicone contained phthalates. I had to recall the entire batch. The cost was devastating—$25,000 in wasted materials and labor.

I personally visited five silicone manufacturers after that disaster. I inspected their facilities. I requested third-party lab reports. I verified their certification documents with certifying bodies.

Due diligence checklist I developed: ✅

- Visit supplier facilities in person

- Request and verify all safety certifications

- Order small test batches before bulk purchases

- Check references from other adult toy manufacturers

- Verify business licenses and corporate registrations

- Establish written quality agreements with penalty clauses

This checklist is now standard for verifying adult toy quality from Chinese suppliers. I share it with clients to help them avoid my mistakes.

Learning About Payment Protection 💸

I lost $10,000 to a motor supplier who disappeared after receiving full payment upfront.

I was naive about payment terms. The supplier offered great prices on vibrator motors. They required 100% payment before production. I trusted them because they seemed professional.

They delivered the first two orders perfectly. On the third order—my largest at $10,000—they vanished. No phones answered. Their factory was empty.

😤 This taught me about payment structures:

- Never pay more than 30% upfront to new suppliers

- Use escrow services or letters of credit for large orders

- Build supplier relationships gradually

- Verify supplier financial stability through credit reports

Today, VF Pleasure's OEM strategies include helping clients establish safe payment terms with component suppliers. We leverage our established relationships to reduce client risk.

🛡️ Want to avoid costly supplier mistakes? Download our free supplier verification checklist based on 15 years of experience.

How Did You Build Trust With International Clients Initially? 🌍

Building trust across cultural and geographic boundaries was my biggest challenge. Chinese manufacturers faced stereotypes about quality and reliability.

I built trust through radical transparency. I invited clients to visit our Dongguan facility. I provided video documentation of production processes. I offered money-back guarantees on first orders. I responded to emails within two hours regardless of time zones. Small gestures like remembering client birthdays and understanding their market needs created lasting relationships.

The Power of Factory Visits 🏭

Nothing built trust faster than bringing clients to our facility.

I started offering fully hosted factory visits in my third year. I covered local transportation and accommodation costs for serious buyers. This was expensive but transformative.

Clients saw our workers following safety protocols. They inspected our material storage conditions. They watched quality testing procedures. They met our design team.

💯 Many clients arrived skeptical. They left as partners. Seeing operations in person eliminated doubts that emails couldn't address.

What clients appreciated most during visits:

- ✅ Watching full production cycles from raw materials to finished products

- ✅ Meeting the team personally and understanding our culture

- ✅ Reviewing quality control documentation systems

- ✅ Discussing customization possibilities with designers directly

- ✅ Understanding our capacity and limitations honestly

Today, we host 20-30 client visits annually. Our Shenzhen R&D center makes visits even more valuable. Clients see innovation happening in real-time.

We document these visits in our guide to choosing adult toy manufacturers. Factory transparency remains our strongest trust-building tool.

Responding to Cultural Differences 🗺️

Understanding different markets required cultural education I didn't have initially.

American clients valued direct communication and speed. European clients prioritized detailed documentation and compliance. Australian clients focused on unique designs that stood out.

I made mistakes. I once promised a delivery timeline that was standard in China but unrealistic for international shipping. The client felt deceived even though I shipped on time by Chinese standards.

📝 I learned to under-promise and over-deliver. If production takes four weeks, I quote six weeks. If shipping takes two weeks, I quote three weeks. This buffer protects relationships.

| Market | Communication Style | Priority | Common Concern |

|---|---|---|---|

| 🇺🇸 United States | Direct, fast-paced | Speed to market | Compliance costs |

| 🇪🇺 Europe | Detailed, formal | Documentation | CE certification |

| 🇦🇺 Australia | Casual, relationship-focused | Unique designs | Shipping logistics |

| 🇨🇦 Canada | Balanced, thorough | Quality assurance | Bilingual packaging |

Understanding these differences transformed our client relationships. Our guide to finding reliable OEM adult toy factories includes cultural considerations that I wish I had known earlier.

What Role Did Trade Shows Play in Your Early Growth? 🎪

Trade shows were my university for the adult toy industry. They accelerated learning that would have taken years otherwise.

Attending the Guangzhou Sex Culture Festival, Shanghai Adult Expo, and later international shows in Germany and Las Vegas gave me market intelligence impossible to get elsewhere. I saw competitor products, met potential clients, learned about trends, and built supplier networks. My first three major clients came from trade show connections.

My First Trade Show Experience 😬

Guangzhou Sex Culture Festival 2010 was intimidating. I had basic samples and even more basic English.

I shared a small booth with another manufacturer to split costs. My display was simple—ten vibrator samples on a black cloth. Other booths had elaborate lighting and professional models demonstrating products.

I felt inadequate. But I stayed the entire three days. I talked to everyone who stopped by. I collected business cards. I took photos of competitor products.

🎓 That show taught me what the market wanted. I saw that clitoral stimulators were gaining popularity. I noticed that rechargeable products commanded premium prices. I learned that packaging quality mattered as much as product quality.

Lessons from my first trade show:

- 📦 Bring more samples than you think you need

- 📝 Take detailed notes on competitor products and pricing

- 🤝 Focus on building relationships, not just making sales

- ⏰ Follow up with every contact within one week

- 👀 Study what draws crowds to other booths

I returned to Dongguan with new ideas. We developed three new products based on show insights. Two became bestsellers.

Today, I attend 4-5 international trade shows annually. Our booth at Shenzhen International Adult Expo attracts hundreds of visitors. We use shows to launch new products and gather market feedback.

Our SZI Expo 2025 guide helps clients maximize their trade show investment.

Networking That Changed Everything 🌟

Trade shows introduced me to people who transformed my business.

I met a German distributor named Klaus at the Shanghai show in 2012. He was frustrated with his current supplier's quality issues. We talked for two hours about manufacturing challenges.

Klaus took a chance on VF Pleasure. His first order was small—1,000 units. But he provided detailed feedback on every aspect. He explained European safety regulations I didn't understand. He shared market research his company had conducted.

🇩🇪 That relationship opened the European market for us. Klaus introduced me to other distributors. He vouched for our quality. Today, European clients represent 40% of our business.

"Trade shows aren't just about displaying products. They're about finding the right people who believe in your vision and help you grow. Klaus taught me that partnerships are more valuable than transactions." 💎

I also met component suppliers at shows. I found the motor manufacturer we still use today. I connected with packaging designers who understood adult product discretion requirements.

Our guide to building distribution partnerships reflects networking lessons learned through years of trade show attendance.

🎯 Planning to attend a trade show? Get our complete SZI Expo 2025 preparation guide to maximize your ROI.

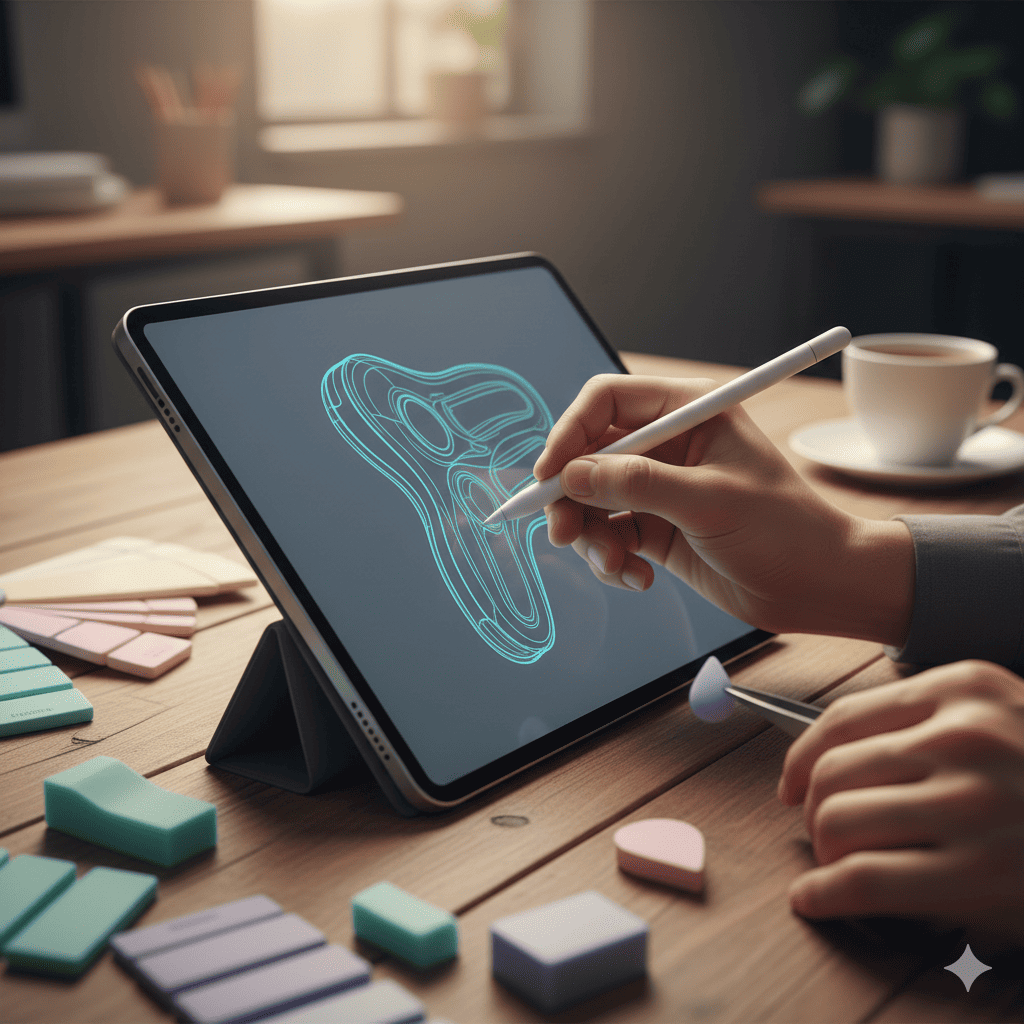

How Did You Develop Your First Custom Product Line? 🎨

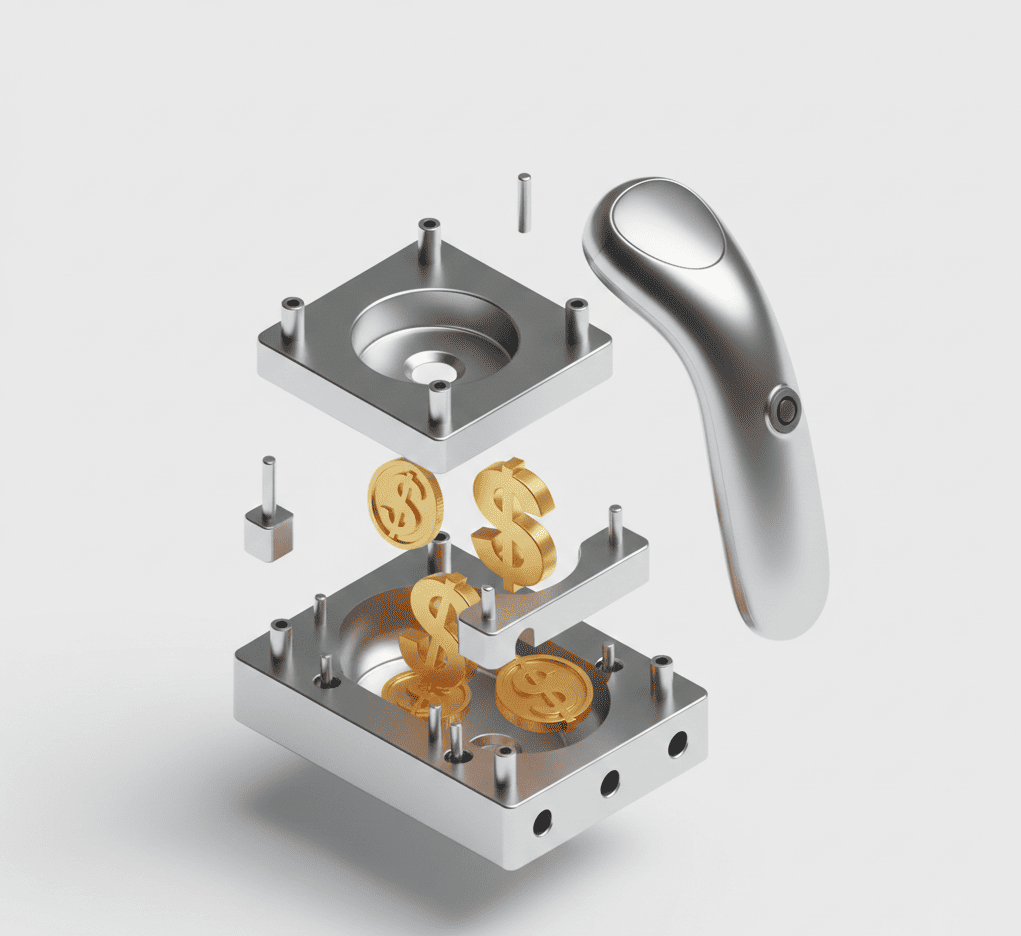

Creating custom products was scary. I worried about development costs and whether clients would actually buy what they ordered.

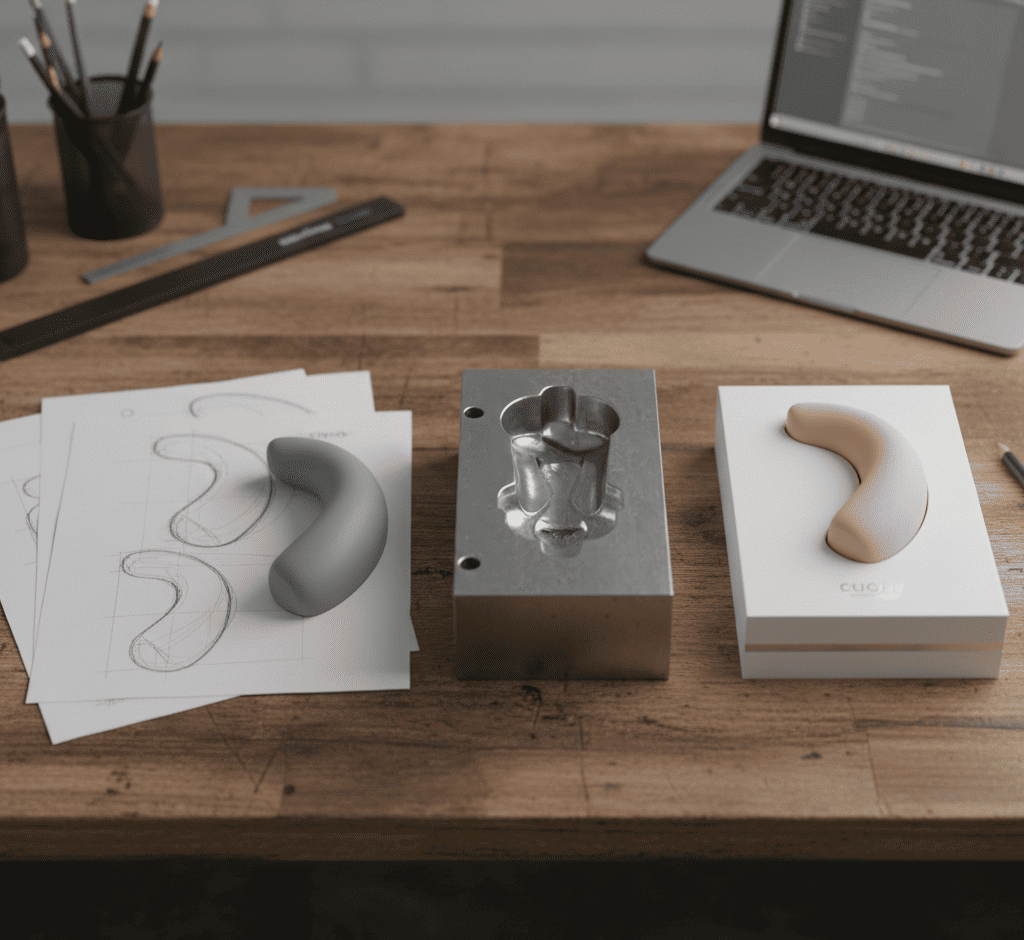

My first custom project came from an Australian retailer requesting a unique rabbit vibrator design. They wanted specific dimensions, dual motors with different patterns, and waterproof construction. We invested $8,000 in mold development and prototyping. The learning curve was steep, but this project established our custom manufacturing capabilities.

Understanding Client Needs Beyond Specifications 🔍

The Australian retailer sent technical drawings. They seemed clear. But drawings don't capture everything.

I scheduled video calls to understand their market. I asked about their target customers. I learned they wanted to serve couples in their 30s and 40s seeking rekindled intimacy.

This context changed everything. The technical specs were just starting points. The product needed to feel approachable, not intimidating. It needed quiet motors for discretion. It needed simple controls for users new to adult toys.

💡 We designed three prototypes:

- Following their exact specifications

- Our interpretation based on market understanding

- A hybrid combining their vision with our manufacturing experience

The client chose the hybrid. They appreciated that we thought beyond just executing their order.

Key questions I learned to ask clients: ❓

- Who is your target customer specifically?

- What problems are they trying to solve?

- What products have they used before?

- What price point are you targeting?

- What makes your brand different from competitors?

These questions became standard in our custom adult toy development process. Understanding client markets makes our custom products more successful.

Managing Prototype Iterations 🔄

We went through five prototype iterations. Each cycle took two weeks and cost $800.

The first prototype had motor vibration that was too intense. The second had a clitoral arm positioned incorrectly. The third had a button design that was confusing. The fourth had waterproofing issues.

Each failure frustrated me. I worried about costs mounting. But the client appreciated our persistence. They saw we were committed to getting it right.

✅ The fifth prototype was perfect. The client ordered 5,000 units. They reordered 10,000 units three months later. That product became a bestseller for them.

| Prototype Stage | Issue Identified | Solution | Cost | Time |

|---|---|---|---|---|

| 🔧 Prototype 1 | Motor too strong | Adjusted motor voltage | $800 | 2 weeks |

| 🔧 Prototype 2 | Arm positioning | Modified mold design | $800 | 2 weeks |

| 🔧 Prototype 3 | Button confusion | Redesigned control panel | $800 | 2 weeks |

| 🔧 Prototype 4 | Waterproofing | Added extra sealing | $800 | 2 weeks |

| ✅ Prototype 5 | Approved | No changes needed | $800 | 2 weeks |

This project taught me that low MOQ custom manufacturing requires patience and iteration. We now offer rapid prototyping to reduce client development timelines.

Our complete guide to OEM vs ODM services explains these processes in detail.

🚀 Ready to develop your custom adult toy? Start with our free product development consultation - we'll help you avoid costly mistakes.

What Would You Do Differently If Starting Again Today? 🔄

Looking back, I see many things I would change. Some mistakes were necessary learning experiences. Others were simply avoidable.

If I started today, I would invest in professional branding and marketing from day one. I would hire an experienced production manager earlier instead of trying to learn everything myself. I would attend international trade shows in my first year rather than waiting until year three. Most importantly, I would focus on fewer products initially and perfect them before expanding.

Investing in Professional Expertise Earlier 💼

I tried to save money by doing everything myself. This was a mistake that cost more in the long run.

I spent six months learning CAD design to create product drawings. I could have hired a designer for $3,000 to do better work in two weeks. My amateur designs delayed product launches and created manufacturing inefficiencies.

I taught myself basic web development to build our first website. It looked unprofessional. Potential clients judged our manufacturing capabilities by our website quality. A $5,000 investment in professional web design would have paid for itself in closed deals.

😓 I handled all customer service emails personally. This limited our response capacity. Hiring a bilingual customer service representative in year two instead of year four would have improved client satisfaction significantly.

Professional services worth early investment: 💰

- 🎨 Product design and CAD modeling

- 🌐 Professional website development with SEO

- ✅ Quality assurance manager with industry experience

- 📞 Bilingual customer service team

- 📸 Professional photography and product documentation

Today, VF Pleasure has specialized teams for each function. Our comprehensive manufacturing capabilities reflect lessons from doing everything inadequately myself.

Starting with Niche Focus 🎯

I tried to manufacture every type of adult toy. This spread resources too thin and prevented excellence in any category.

We made vibrators, dildos, anal toys, male masturbators, and couples toys simultaneously. Each category required different materials, expertise, and market understanding.

💡 If I started today, I would focus exclusively on vibrators for the first two years. I would perfect materials, motors, controls, and waterproofing. I would become known as the best vibrator manufacturer before expanding.

Specialization builds reputation faster. Clients remember specialists, not generalists.

Our current product categories reflect eventual focus:

But we developed these capabilities sequentially, not simultaneously. Our guide to starting an adult toy business emphasizes focused growth.

Building Digital Presence Sooner 📱

I underestimated online marketing. I thought trade shows and word-of-mouth were sufficient.

The adult toy industry moved online faster than I anticipated. By year five, most buyers researched suppliers online before trade shows. Our weak digital presence meant we weren't even being considered.

We didn't start serious content marketing until year seven. We should have started in year one.

🌐 If I restarted today, I would:

- Launch a professional website immediately

- Publish educational content about manufacturing processes

- Document our quality standards and certifications online

- Share client success stories (with permission)

- Engage on LinkedIn and industry forums

- Invest in SEO to rank for relevant keywords

Our current content strategy includes comprehensive guides like choosing silicone sex toy manufacturers and understanding OEM adult toy manufacturing. These resources attract qualified leads and establish authority.

Starting these efforts earlier would have accelerated growth significantly. 📈

Conclusion 🎉

Starting VF Pleasure taught me that success in adult toy manufacturing requires patience, transparency, and constant learning. The journey was harder than I imagined but more rewarding than I hoped. Focus on quality, build genuine relationships, and grow sustainably. 💪

🚀 Ready to Start Your Adult Toy Business Journey?

Don't make the same mistakes I did. Let VF Pleasure's 15 years of experience guide your success.

What We Offer:

- ✅ Custom OEM/ODM Services with low MOQ

- ✅ Fast prototyping (2-week turnaround)

- ✅ Body-safe materials with full certifications

- ✅ Free factory tours and consultation

- ✅ Transparent pricing and quality guarantees

📞 Take Action Today:

- 🌐 Visit VF Pleasure to explore our capabilities

- 📧 Contact us for a free consultation on your project

- 📚 Download our complete OEM/ODM guide

- 🎪 Meet us at SZI Expo 2025

💬 Questions? Comments? Share your own startup story below!

We love hearing from fellow entrepreneurs in the adult toy industry. Let's learn from each other. 👇

📌 Related Articles You'll Find Valuable:

- How to Choose a Reliable Adult Toy Manufacturer

- Complete Guide to Private Label Sex Toys

- Adult Toy Market Trends 2025-2030

- Body-Safe Materials Guide

© 2025 VF Pleasure | Quality Adult Toys Manufacturing Since 2010 🏭